PBJ Engineering Services Ltd

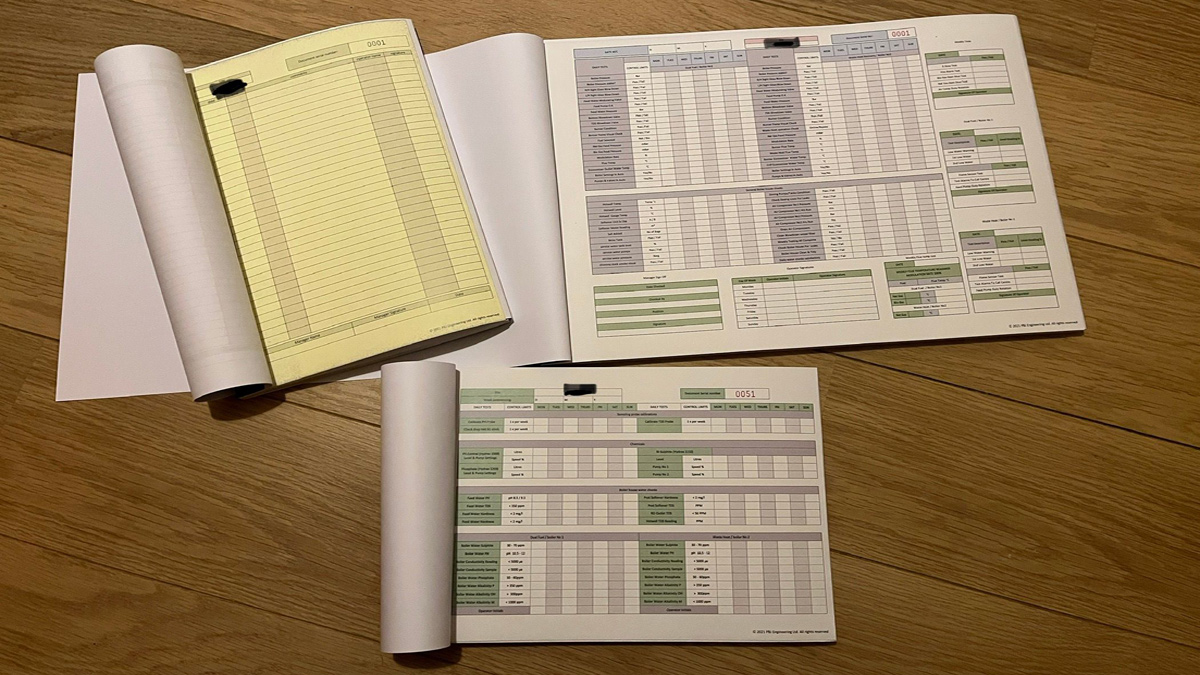

Reverse Osmosis System at a Major Sewage Treatment Works

Courtesy of PBJ Engineering

The challenge

The steam boilers at the STW were facing an operational headache. High levels of Total Dissolved Solids (TDS) in their main water supply meant the boilers had to frequently release water. And not just any water — scalding hot, 185-degree water under 10 bar pressure. The process was energy-draining as each release required more fuel to bring the incoming water back up to temperature.

Our team at PBJ Engineering, alongside our partners Lubron and Roger Huelin & Co Ltd, were entrusted with a critical mission: to introduce an effective water purification solution that could address this challenge.

The solution

Enter the Reverse Osmosis (RO) plant, provided by Lubron. Integrating this plant drastically reduced the boiler’s need to release water. By controlling the release, the boilers consume less energy, translating into noticeable savings. Beyond energy conservation, there were added benefits: the boiler’s chemical treatment needs were curtailed due to reduced wastage, and a cleaner water feed minimised the risk of internal scaling.

Courtesy of PBJ Engineering

One of the stand-out features of our approach was the care taken to minimise operational disruptions. Our meticulous planning ensured that the RO plant’s integration only led to a brief half-day interruption. What’s more, our team introduced extra valves and bypass routes to the design, ensuring that should any unexpected issue arise, the system would smartly bypass the RO plant, guaranteeing zero downtime.

During our installation, we unearthed inefficiencies in the site’s existing water-softening plant. In order to take the opportunity during the planned downtime, we took the initiative to overhaul this unit, further enhancing the site’s operational efficiency.

Added value

Our initial assessment laid the groundwork for a cost-to-savings projection. According to our calculations and in collaboration with our partners, the system was on track to pay for itself in approximately two-and-a-half to three years. Almost two years post-installation, the RO plant has showcased its reliability with no reported failures, echoing our commitment to delivering lasting solutions.

Courtesy of PBJ Engineering

Paul Collins from Lubron echoed this stating;

“As a result and due to the success of this project, we are finding the business for boiler treatment increasing now due to sites wanting to eliminate some of the chemical treatment. Also the cost saving in water use and energy for blow downs significantly and quickly pays for an RO system”.

Such projects resonate with PBJ Engineering’s ethos. Guided by Paul Johnson’s expertise our team blends technical know-how with practical solutions, ensuring that clients reap the rewards of both immediate efficiency and long-term value.