Steve Vick International Ltd

800m Pipeline Rehabilitation

Hexi Trailer - Steve Vick International

The regional water and sewerage company, which serves 2.8 million customers across the south west of England, purchased six Hexi Trailers in 2013. The trailers have been put to good use ever since, and are currently employed on 70% of water main replacement projects.

This recent project took place in Calne, Wiltshire and involved replacing 800m of cast iron water main originally laid in the 1920s. The main had reached the end of its life, and Wessex Water wanted to ensure that customers were provided with a reliable and clean water supply by replacing it with plastic pipe.

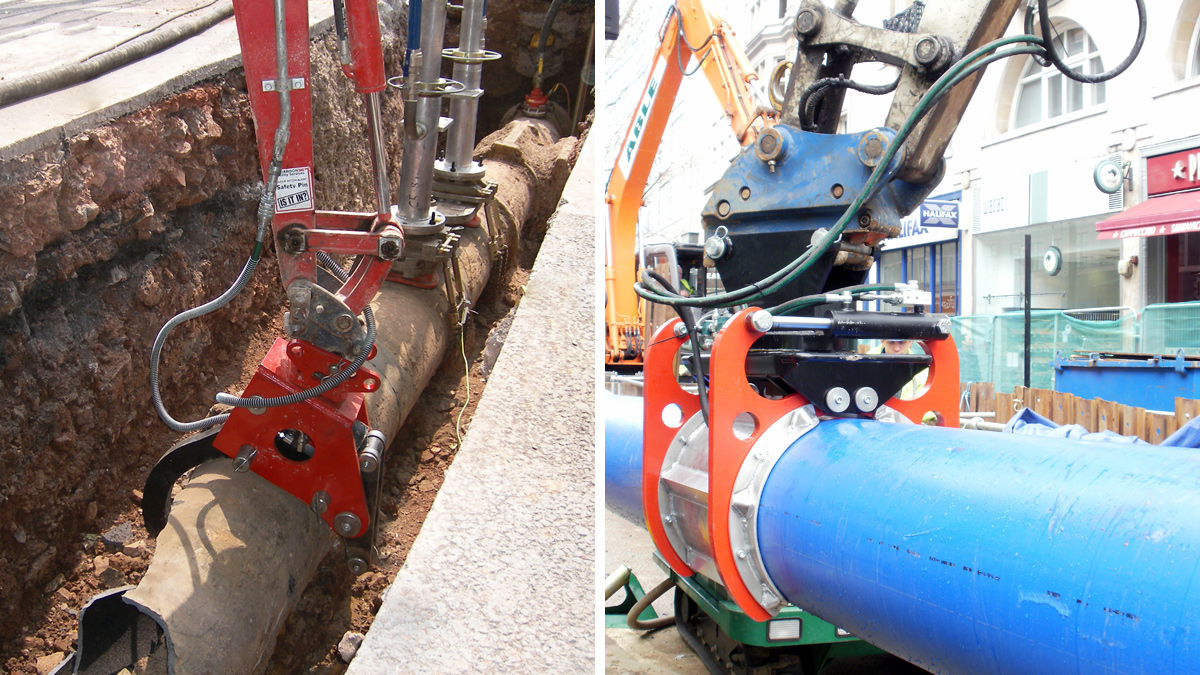

The new plastic pipe was inserted into the old cast iron main using another SVI product – the Pipe Handler.

By using this method, Wessex Water were able reduce the number of ground excavations and speed up the replacement process.

500m of pipe inserted in one push

The high capacity Hexi Trailer, loaded with a 500 metre coil of 63mm diameter PE, allowed operatives to insert 800m of pipe in just two pushes, one of 500m and the second of 300m. The coils of pipe were manoeuvred on site and the pipe accurately inserted into the old water main by the SVI Pipe Handler attached to an excavator; an insertion rate of 300m per hour was achieved.

Only one excavation was needed, leading to minimum disruption and reinstatement costs. Alternative methods of replacement would have involved digging down every 100m.

Using a high capacity trailer and mechanised pipe handling equipment helped ensure this replacement project was completed within two days.

New Design

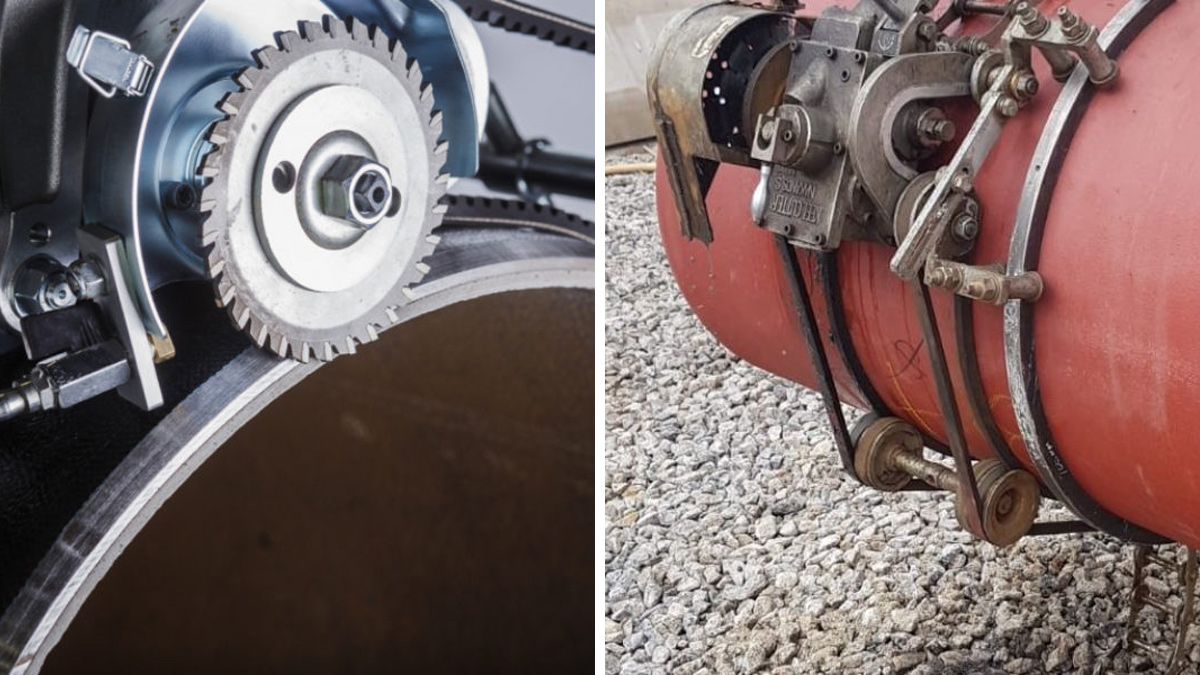

The Hexi trailer was a completely new design for SVI when it was introduced in 2012. It is capable of dispensing coiled pipe with diameters of 63mm-90mm and has a number of key advantages. Firstly, by taking a 500 metre coil rather than the usual 100 or 120 metres, it allows operators to save money by reducing pipe wastage.

Secondly, due to the hydraulically powered raised hexagonal drum, the pipe is dispensed smoothly and quickly.

The easy operation allows one operative to dispense the pipe compared with other trailers on the market which require two or even three people. Safety was a key consideration when developing the Hexi trailer, with the result that all loading and dispensing procedures are carried out from ground level and both ends of the pipe are secured until the moment of dispensing to prevent the PE ‘springing away’ thus avoiding an injury hazard.

Insertion made faster and safer

SVI developed their Pipe Handlers to make the process of inserting plastic pipe easier, safer and faster.

There are five models in the range accommodating pipe diameters from 40mm to 630mm. All models attach to a quick hitch or standard bucket pins of most common hydraulic excavators. Loading, manoeuvring and inserting operations are easily controlled from the safety of the excavator cab.

For more information: Steve Vick International Ltd | +44 (0)1225 864864 | www.stevevick.com