Steve Vick International Ltd

4.5km Slip Lining Project

Hexi Trailer - Steve Vick International

Van Voskuilen, who act as SVI’s sole agent in the Netherlands, inserted 4.5km of 90mm PE into a 4” asbestos main in Hardenberg in the east of the country. To aid safety and efficiency during the project, the company used the SVI Mini Pipe Handler and the Hexi pipe coil Trailer.

Reduced pipe wastage

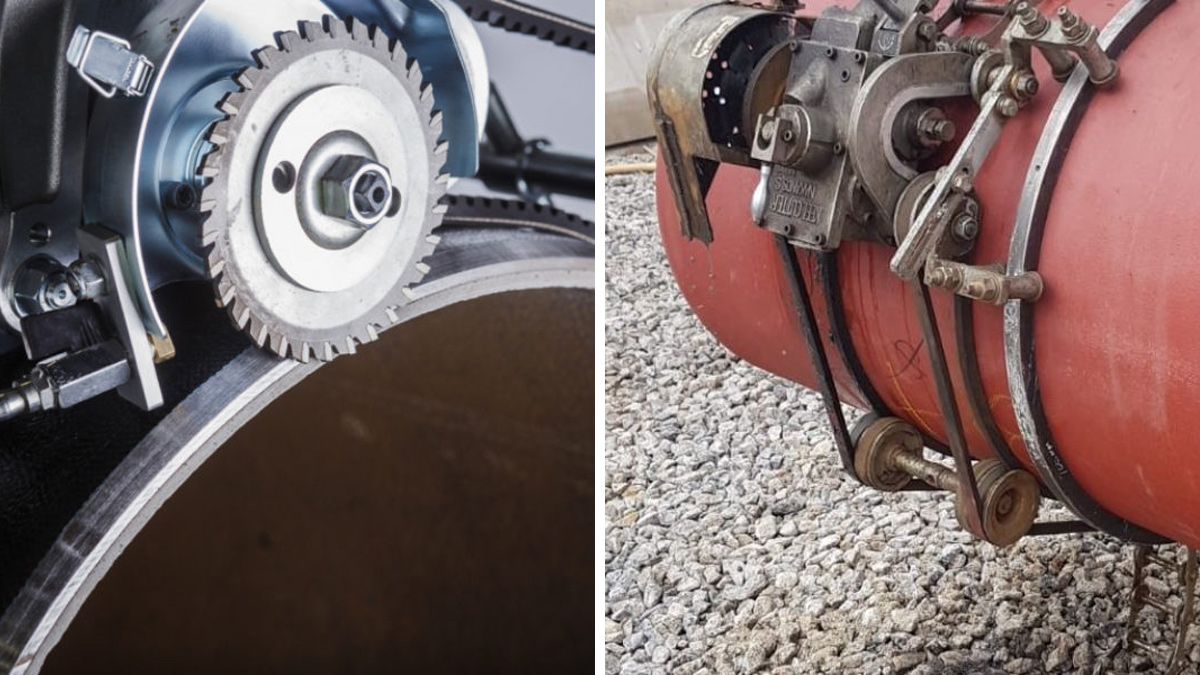

The Hexi Trailer is capable of dispensing coiled pipe with diameters of 63mm to 125mm. A major advantage of the trailer is that by taking a 500 metre coil (63 – 90mm) rather than the usual 100 or 120 metres, it allows operators to save money by reducing pipe wastage when used over several projects, as the quantity of unused ‘ends’ of pipe is minimised.

With its hexagonal drum, which is raised and lowered hydraulically, the Hexi Trailer allows pipe to be pulled off smoothly, quickly and in a controlled manner. The trouble-free operation allows one operative to dispense the pipe compared with other trailers on the market which require two or even three people.

With safety a key consideration in the design of the Hexi Trailer, all loading and dispensing procedures are carried out from ground level and both ends of the pipe are secured until the moment of dispensing to prevent the PE ‘springing away’ thus avoiding an injury hazard.

Insertion controlled from digger cab

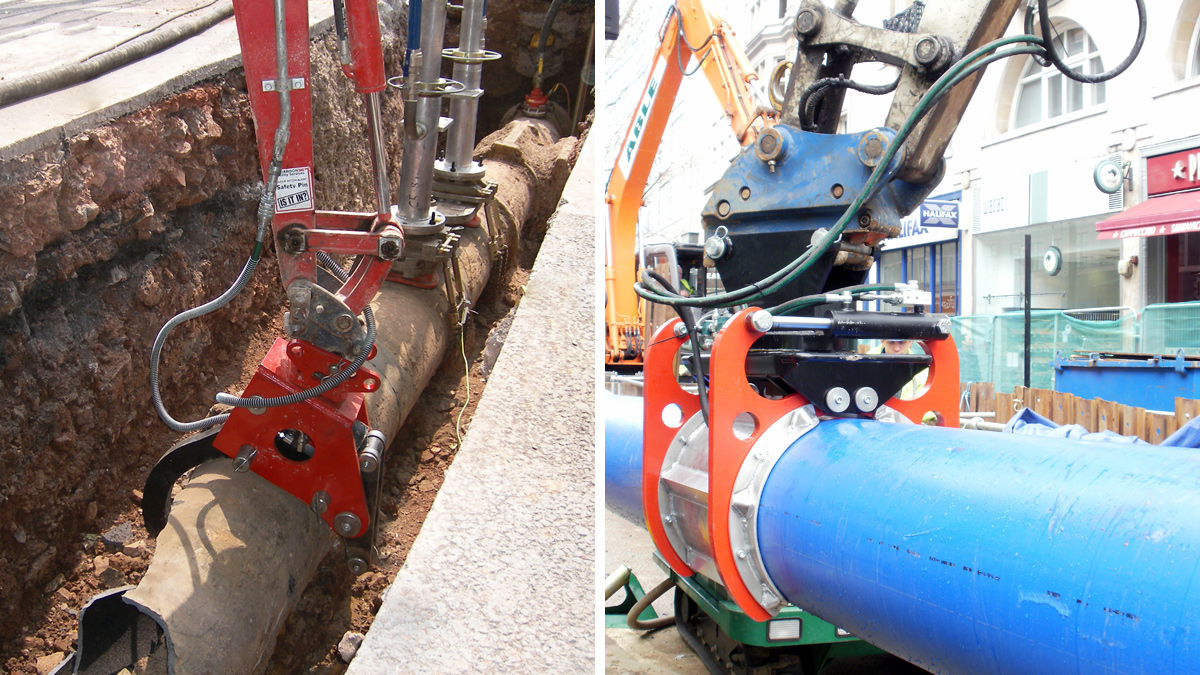

To speed up the insertion process, Voskuilen used the Mini Pipe Handler. SVI’s range of Pipe Handlers attach to the quick hitch or standard bucket pins of most common hydraulic excavators to make the process of inserting plastic pipe easier, safer and faster. There are five models available to accommodate pipe diameters from 40mm right up to 630mm. Loading, manoeuvring and inserting operations are easily controlled from the safety of the excavator cab meaning that operators do not have to enter the trench.

Asked why slip lining was chosen as the replacement method, Van Voskuilen Director, Albèr van Ee, said:

“There was considerable damage to the old main which needed to be replaced. As there were many trees on the course of the main there was insufficient space to lay a new pipe so insertion was the preferred option”.

Active throughout the Netherlands, Van Voskuilen designs, installs and maintains pipes, ducts and cables including gas and water mains and electricity cables. The company is the sole agent in the Netherlands for all SVI products and techniques for the trenchless repair, renovation and decommissioning of pipes. Vitens supplies 5.6 million customers and manages 49,000 km of water mains in the Netherlands.

For more information: Steve Vick International Ltd | +44 (0)1225 864864 | www.stevevick.com