Steve Vick International Ltd

Pipe Handler

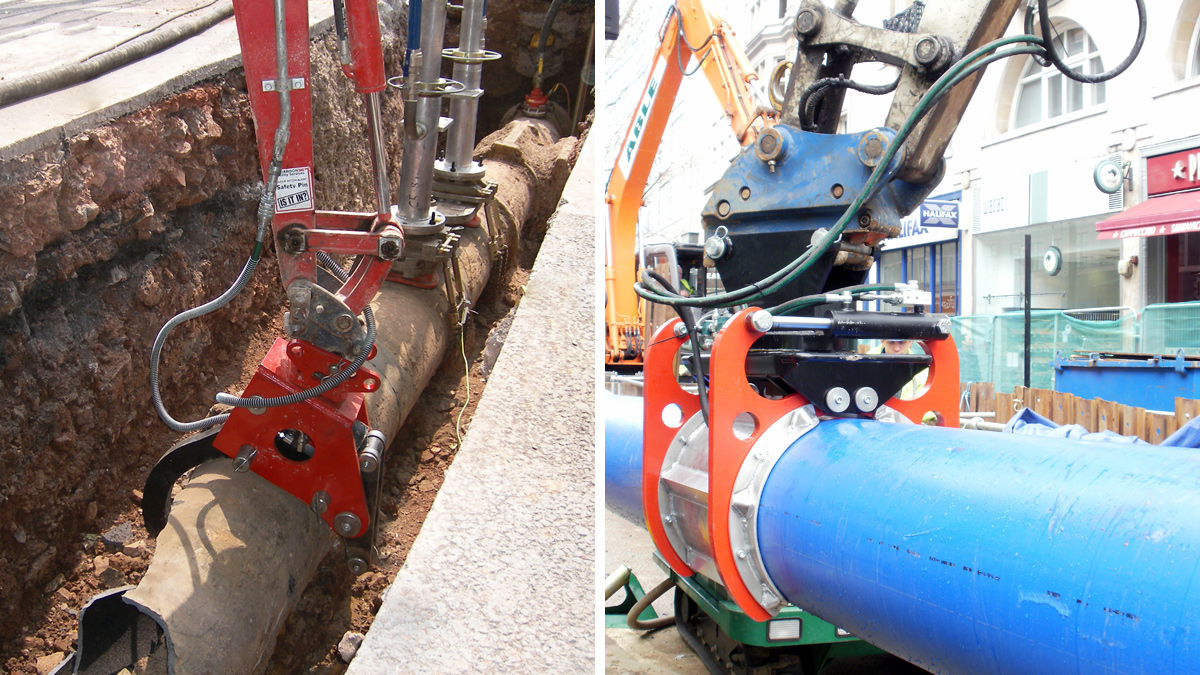

(left) small diameter Pipe Handler and (right) large diameter Pipe Handler

The regional water and sewerage company, which serves 2.8 million customers across the south west of England used directional drilling to replace the sewerage pipe which ran across farmer’s fields on the outskirts of Salisbury. In order to replace the 1km stretch, several different lengths of pipe needed to be inserted, ranging from 70m to 120m. To achieve these lengths, individual 12m sticks of PE were butt fused together.

The SVI Pipe Handler was used to pull the pipes that had already been joined into place, these pipes sometimes extended to many metres in length. Once the pipe was in place the pipe handler unloaded the next 12m stick and lifted it into the correct position for butt fusion.

Traditionally when manoeuvring PE pipe on site an excavator bucket and sling would be used. However, this can cause the pipe to swing and become unstable which can be a hazard to operatives. The benefits of using the Steve Vick International Pipe Handler are that it is a single person operation which requires a one stage set up for the whole process. Once in place the pipe handler can be controlled entirely from the cab, avoiding the need for operatives to handle the pipe. This reduction in the man handling of the pipe not only improves safety but is also more time efficient.

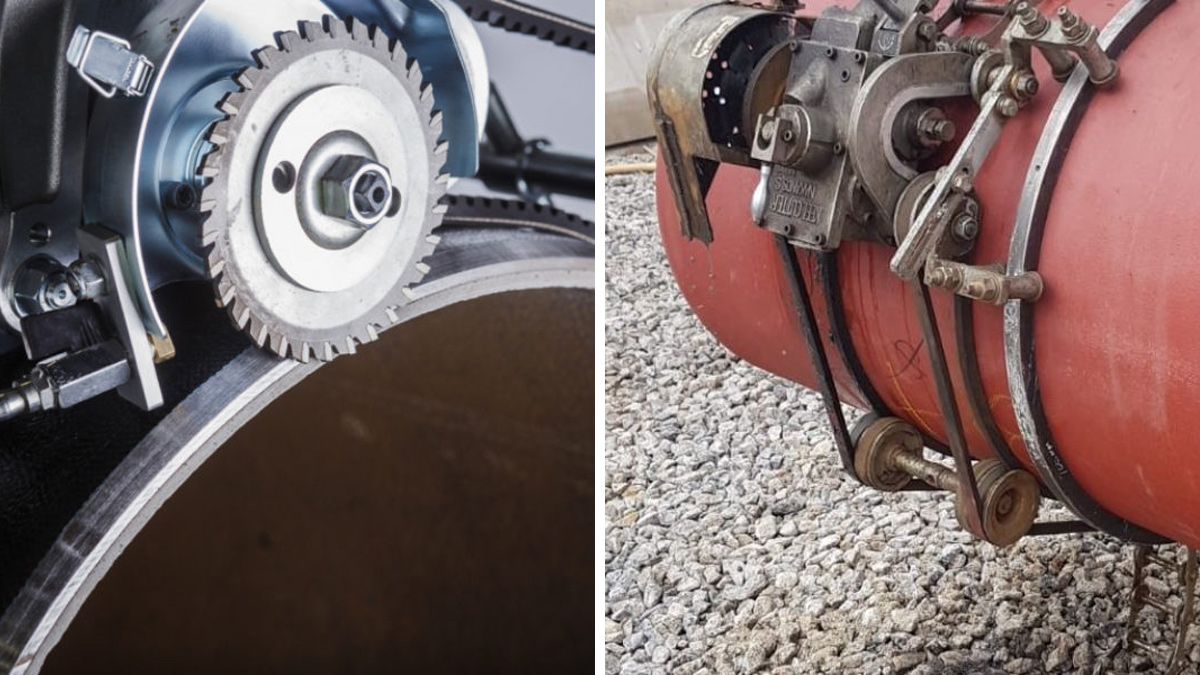

How Does The Pipe Handler Work?

The Pipe Handler is a highly efficient addition to the tools available on site. It enables sticks of PE to be loaded or unloaded safely from storage racks or lorries and loaded into the butt fusion machine. The Pipe Handler is also designed to slipline pipe by gripping the PE,positioning it in the excavation and inserting the pipe. The entire operation is controlled from the cab, avoiding the need for operatives to handle the pipe or enter the trench.

There are three models in the range handling pipe diameters from 250mm up to 900mm in diameter. Each model is capable of handling various diameters using shell inserts.

Available for hire or purchase, the SVI Pipe Handlers connect to the arm of most common 5-8 tonne hydraulic excavators and can achieve pushing speeds of 10 metres per minute with lengths of 500+ metres being pushed at one time.

For more information: Steve Vick International Ltd | +44 (0)1225 864864 | www.stevevick.com