Loggerheads Village, located in north-west Staffordshire, was previously served by two separate Sewage Treatment Works (STW); Loggerheads Village, now know as Sanatorium Transfer Pumping Station (TPS), and Loggerheads Sanatorium STW. The £17m AMP7 Q WFD upgrade project represents a significant investment in wastewater infrastructure by Severn Trent, which has been designed to enhance environmental compliance, improve water quality, and implement advanced treatment technologies; notably a DfMA membrane bioreactor (MBR) system.

Project background

The original project comprised an outline design to improve and redevelop Sanatorium STW with flows forwarded from the ‘old’ Village STW (now called Village TPS) to Sanatorium to be treated and returned. However, this solution was not feasible due to Sanitorium STW having access limitations and general site constraints.

The project was redesigned to incorporate a third location at the site of the ‘old’ village reed beds (now called Village STW). Upgrades here were built off-line and comprise a PST distribution splitter chamber, two PSTs, an MBR system, de-sludge and sludge tanks, chemical dosing and sludge thickening. Flows from Village TPS will still be forwarded for treatment at the Sanatorium site, enabling full flow treatment from both catchments to be screened and the sent to Village STW for full treatment, from where flows will be split back to each respective site’s FE sample chamber for quality monitoring.

[caption id="attachment_25475" align="alignnone" width="1200"] (above right) Google Maps image showing locations of sites and (left) simplified schematic showing site interconnections - Courtesy of Coffey[/caption]

Objectives & project scope

The goal of the project is to meet tightened discharge permits and improve operational efficiency and resilience, by upgrading and replacing outdated infrastructure and implementing a new, innovative technology for enhanced treatment.

The scope of the project is extensive and included the following:

A new inlet works package from SPIRAC Ltd.

Shaft tank PS with storm retention constructed by Active Tunnelling Ltd.

Two new stainless steel circular PSTs from Stortec Engineering Ltd complete with new scraper bridges.

A modular containerised three-stream MBR treatment plant and MBR equalisation tank from Coftec with internal technical room chemical dosing.

Sludge treatment facilities including a Huber Technology containerised S-DISC thickening plant and sludge storage.

Transfer pumping stations including a new outfall pumping station returning flows to the respective outfalls via new rising mains between sites.

New Fe chemical dosing plant from Colloide to meet specific dosing requirements of the new MBR.

Final effluent monitoring from Servitech International Ltd.

Extensive mechanical and electrical works and new control systems across the sites.

[caption id="attachment_25484" align="alignnone" width="1200"] New SPIRAC Ltd inlet works package plant - Courtesy of Coffey[/caption]

Inlet works

Coffey appointed SPIRAC Ltd to deliver the new inlet works package. This comprised a new stainless-steel reception tank where the forwarded flows from Village TPS would be blended with the current Sanatorium flows before passing through inlet screens. The inlet works package included:

Two FINEGUARD™ screens (duty/standby) sized for a 700mm wide x 1000mm deep channel, with each capable of screening 81 l/s.

A 7m screw conveyor capable of handling <3.0m3/hr.

Two SPIROWASH® screenings washing units, each capable of handling up to 2.5m3/hr volume. The units receive screenings from the screw conveyor and clean, dewater and compact the screenings, before discharging via press tubes into a skip.

Support structure for the packaged inlet works installed on dedicated concrete pad.

Full steel platforms and access stairs.

PST tanks & splitter chamber

Stortec Engineering Ltd installed two 12m diameter primary settlement tanks constructed from ULTRASTORE® high-grade stainless-steel panels. Each tank will be installed with a reverse U-type GRP launder channel fitted with V-Notch weir plates, scum boards and associated drop box. Each PST will be fitted with rotating half bridge scrapers.

The 4.6m x 3.1m x 2.8m cast in situ PST splitter chamber was constructed by DS Construction (UK) Ltd. This was installed with a PST bypass and penstock control. Steel access platforms and stairs were provided by Steelway.

[caption id="attachment_25481" align="alignnone" width="1200"] Stortec Engineering Ltd ULTRASTORE® PST tanks and scraper bridges - Courtesy of Coffey[/caption]

Membrane bioreactor (MBR) technology

The MBR system is designed to meet stringent discharge permits and deliver high-quality effluent. Each MBR process stream includes fine screens, denitrification tanks, containerised Oxi/aeration tanks equipped with FBDA membrane diffusers and blowers, six membrane modules per stream, and a technical room fitted with pumps for membrane cleaning, chemical dosing and blowers.

The MBR system is a complex, innovative challenge to develop a containerised solution that conforms to Severn Trent’s requirements and standards. The system had to be developed to incorporate redundancy during design, which meant a shift-away from technical room mounted local control panels to an intelligent MCC for each stream. The FFT of 22.5 l/s is ditributed evenly across three streams vis a new equalisation tank. Constructed by DS Construction, the equalisation tank is 17.3m long x 12m wide with a depth ranging from 4m to 5.2m at the sump. A steel access system was constructed by Steelway along the width of the tank with each MBR stream fed via pumps with power and control from the MBR MCCs.

To accommodate the MBR system, an extensive civils programme had to be undertaken to provide all feed and permeate pipework, drainage, washwater, manholes, ducting and draw pits to each stream. Once all services were in place, a base slab was constructed for each stream.

[caption id="attachment_25489" align="alignnone" width="1200"] Installation of the containerised MBRs - Courtesy of Coffey[/caption]

The MBR system was manufactured by Coftec with membranes from Blue Foot Membranes. The system is a modular containerised arrangement comprising three parallel treatment streams, each engineered for optimal biological and membrane filtration performance. All the tanks have been coated with protective coatings from Belzona Ltd, expertly prepared and painted by Barnett Engineering.

Upon delivery to site, the MBRs were craned into position onto the pre-constructed bases prior to the end of 2024. Extensive mechanical works were undertaken by Jones Site Services & Installation (JSS&I) and electrical installation works by Elsym Installations Ltd.

Membrane bioreactor (MBR) design parameters & flow management

Total flow to full treatment

22.5 l/s, distributed evenly across three streams (7.5 l/s per stream)

Bioreactor MLSS

10,000 mg/l

MBR peak flow handling

Up to 22.5 l/s, with excess flows diverted to the storm tanks

Membrane tank MLSS

13,500 mg/l

Equalisation tank

Balancing flow between 37.5 l/s to 22.5 l/s assuming all treatment streams operating

Nominal net flux

23.6 l/m2/h

Recirculation ratio

2.9 (to ensure effective biological treatment)

Backwash flux

55 l/m2/h

To meet the obligations of Severn Trent, one of the MBRs was partially commissioned and placed into service in March 2025. This provided valuable data and verification of performance of the MBR technology. Construction of all three MBR streams was completed by the autumn of 2025.

[caption id="attachment_25479" align="alignnone" width="1200"] MBR Oxitank (left) Bluefoot membrane installation and (right) fit-out in tanks coated with Belzona protective coatings applied by Barnett Engineering - Courtesy of Coffey[/caption]

Loggerheads Sanitorium STW: Supply chain - key participants

Principal designer & contractor: Coffey Construction Ltd

Design: Doran Consulting

Survey: Murphy Geospatial

H&S inspection & CDM: Hurst Setters

Ground investigation: Card Geotechnics Limited

Ecology & hedge removal: Three Shires Ltd

Ecology & tree removal: RammSanderson Ecology

MBR design & supply: Coftec

Temporary works design: BSP Consulting Ltd

Shaft design & construct: Active Tunnelling

Main pipeline installers: A Thomas Plant Hire (ATP)

Directional drillers: GMAC Utilities Ltd

Mechanical installation: Jones Site Services & Installation Ltd

Electrical installation: Elsym Installations Ltd

Civil works: DS Construction (UK) Ltd

Civils package (Sanatorium): Fortel

Slide rail shoring system: National Trench Safety UK

Buried service & pipe integration: Fincher Utilities Ltd

Pressure testing: JMC Northern Limited

Temporary pumping equipment: Pump Supplies Ltd

MBR protective coatings: Belzona Ltd

MBR protective coating application: Barnett Engineering Ltd

MBR access metalwork: Midland Structures Ltd

Ancillary metalworks: Structural Fabrications Ltd

Inlet works/screens: SPIRAC Ltd

Sludge thickening unit: Huber Technology

PSTs: Stortec Engineering Ltd

Storage & buffer tanks: Goodwin Tanks

RAM desludge pumps: EMS Industries Ltd

MCC package for MBRs: Te-Tech Process Solutions

MCCs & telemetry: RSE Control Systems (Blackburn Starling Ltd)

Lagging & trace heating: Jade Insulation Ltd

Access systems: Steelway Ltd

Fibre systems: PEICA Systems Ltd

Pumps supply: Xylem Water Solutions

Chemical dosing: Colloide

GRP kiosks: NPS Engineering Group

MBR instrumentation: Endress+Hauser

Quality instrumentation: Servitech International

Flow instrumentation: Siemens

Generators: WB Power Services

Site buildings: SpaceBuilder

Crane hire: Dewsbury & Proud Ltd

Plant hire: Flannery Plant Hire (Oval) Ltd

[caption id="attachment_25490" align="alignnone" width="1200"] Temporary works: (top left) pipe and chamber installation works, (bottom left) for the Village STW main MCC and (right) for the construction of the works return PS - Courtesy of Coffey[/caption]

Inter-site infrastructure & civil works

In total, over 1.7 km of pipelines were laid using various techniques including pipe ploughing, open cut works and horizontal directional drilling (HDD) under roads and watercourses.

Rising mains (pipe ploughing): Pipe ploughing was undertaken by ATP Cable Plough for nearly 1km of three rising mains, two fibre ducts and one National Grid HV supply between Sanatorium and Village STW.

This innovative method was selected by Coffey because of environmental and ground reinstatement issues; the cable plough’s efficient and low-impact method means that any complications when restoring and subsequently handing back land are dramatically reduced.

Pipe ploughing is effective on almost any terrain and because it causes minimal disruption to the ground’s geological structure, it offers a significant reduction in time, money and risk for the client and contractor. This is particularly significant when working in areas which are particularly sensitive to ecological and environmental issues. It also works very effectively on soft ground and marshland and consequently, it provides designers with an opportunity to soften the impact of schemes when route planning.

Added to this, as it cuts, installs and back-fills all in one operation, pipe ploughing eliminates any risk of trench-collapse and associated health and safety concerns, resulting in a huge increase in productivity over traditional ways of working.

Rising mains - A53 crossing: The A53 crossing required 6 (No.) 80m HDD shots at a depth of 4.0m as stipulated by the local authorities. This incurred the challenge of a significant element of open cut works to link the pipe ploughed runs to the HDD pipework, as ploughing is limited to a 2m maximum depth. Fincher Utilities Ltd was brought in to fulfil this requirement, along with all associated SRD pipework welding and setting out.

[caption id="attachment_25486" align="alignnone" width="1200"] (left) Rising main pipe ploughing and (right) pipe ploughing to HDD integration - Courtesy of Coffey[/caption]

Rising mains - Hemphill Brook crossing: Because of limited point-to-point visibility caused by forestry, newt lakes, and the brook itself, the crossing required 6 (No.) 120m gyroscopic drill shots. Additionally, this required a considerable amount of open cut work to connect the ploughed runs to the HDD pipework.

Due to the client-driven changes with the design and land access, the pipelaying work fell during the winter months, with challenging weather conditions; in particular significant rainfall and high winds bringing trees down along the main Sanatorium access route. Throughout this stage of the project, the project team operated in 24-hour shifts to achieve the completion date of December 2024 for this phase of the works.

Due to challenges found during the HDD drilling processes, accumulated air within the rising mains was found during commissioning; resulting in additional open-air vents and air release valves. During design, the intent was to mitigate this requirement due to the field being used for farming activities where significant complications of in-field structures would have been present. An innovative adaptation in the design was for a designated kiosk to be positioned in a safe location on the field boundary.

[caption id="attachment_25487" align="alignnone" width="1200"] Ongoing operations when working 24 hours/day - Courtesy of Coffey[/caption]

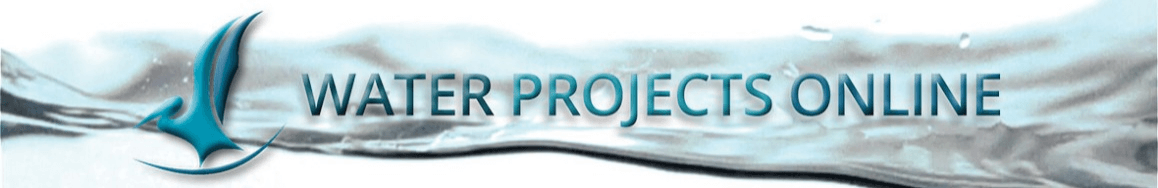

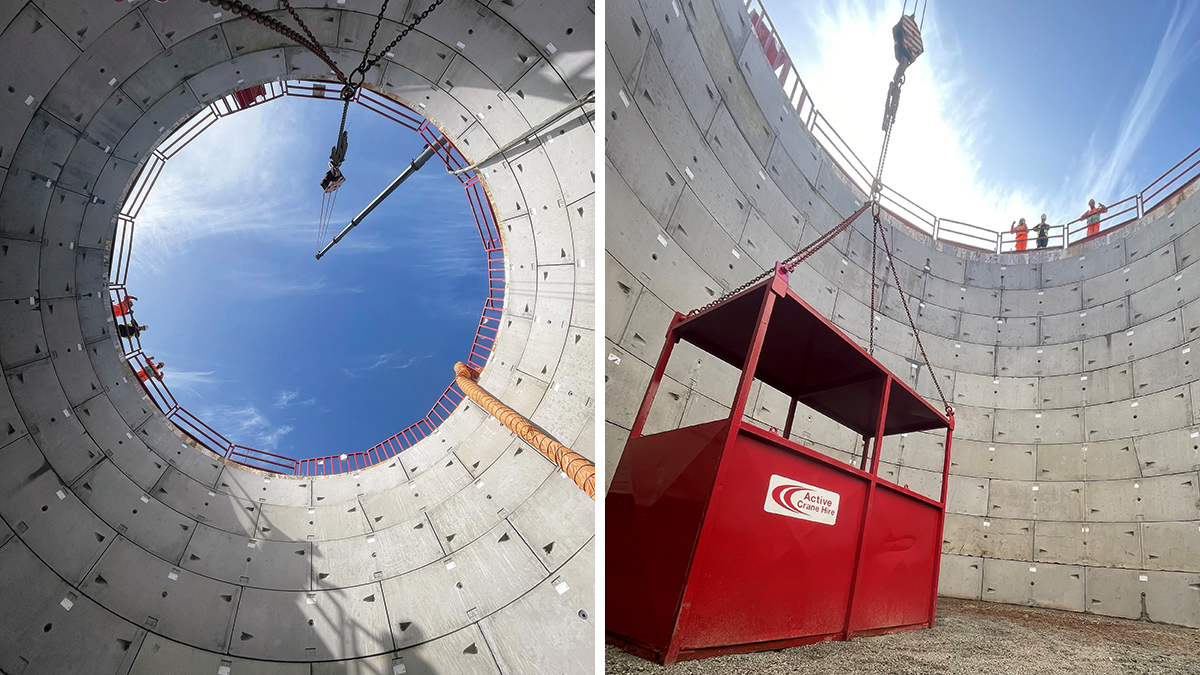

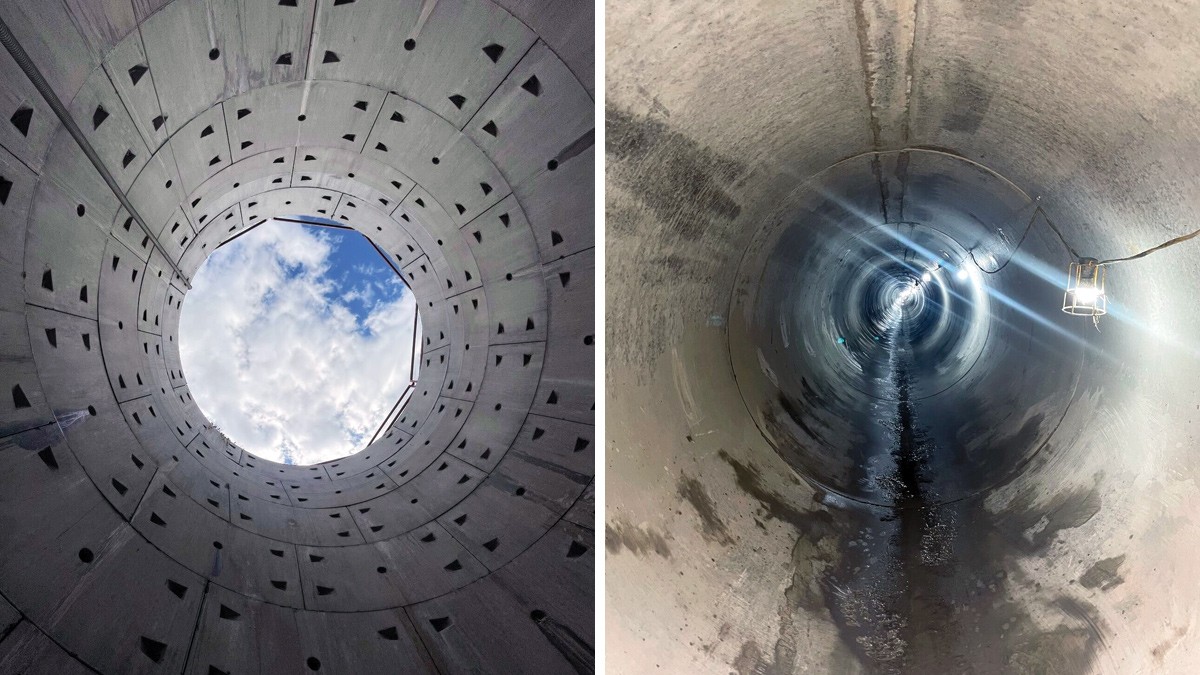

Sanatorium transfer pumping station shaft tank

The transfer pumping station shaft tank was required to transfer crude FFT flows to the Village STW. The pumping station incorporates stormwater storage capacity of 320m3, duty/assist/standby transfer pumps, access steelwork, a UMON4 MCERTS flow meter on the pumping main to Village STW, a bypass arrangement for tank maintenance and an EDM level sensor for UMON3 compliance.

The transfer pumping station shaft tank at Sanatorium was designed and constructed by Active Tunnelling Ltd and the scope included:

A 7.5m deep, 10.5m internal diameter shaft.

Reinforced concrete guide collar.

Install 7 (No.)10.5m ID precast concrete segmental rings, build to one ring above collar level.

250mm deep drainage blanket including sump pipe and 100mm blinding.

Reinforced concrete base slab 1.25m deep.

Grouting the shaft anulus.

Mass concrete benching to a maximum depth of 1.15m including forming sump.

[caption id="attachment_25483" align="alignnone" width="1200"] Sanitorium TPS shaft tank - Courtesy of Coffey[/caption]

Chemical dosing

Colloide provided chemical dosing plant and ferric sulphate storage with a walk-in dosing kiosk for four-point simultaneous dosing in accordance with Severn Trent’s template design. The primary dosing point is into PST distribution chamber. The secondary dosing location is into each of the three denitrification tanks and is configured to forward feed control based on the pre-MBR ortho-P monitor and the MBR stream feed pumping station flow.

Each dosing point and MBR stream has duty/standby pumps with automatic switchover to the standby; requiring eight pumps in total. Standby dosing lines are required to each duty dosing line; requiring 16 dosing lines in total.

Colloide provided 10m3 of ferric sulphate storage capacity along with chemical reception, chemical storage, and dosing kiosk bunds, and dual-contained dosing lines with capped off dual-contained standby lines. Emergency shower and eyewash stations are installed at the chemical dosing area, the poly dosing kiosk and the MBRs.

Sludge thickening

The sludge thickening solution is a containerised S-DISC thickener from Huber Technology. In addition, a glass coated sludge buffer tank and thickened-sludge holding tank were supplied by Goodwin Tanks along with duty/standby primary settlement tank desludge pumps from EMS Industries Ltd.

The S-DISC sludge thickener is a robust, efficient and reliable system using a long-life stainless steel filter cloth with minimal water, energy, and chemical usage. It offers a number of benefits including a compact design with a high sludge volume reduction of up to 90% and reduced disposal costs.

[caption id="attachment_25478" align="alignnone" width="1200"] (left) Huber S-DISC sludge thickener and (right) Goodwin Tanks sludge tank installation at Village STW with mechanical installations by JSS&I - Courtesy of Coffey[/caption]

Electrical & control systems

The electrical infrastructure is designed to support a complex array of mechanical, process, and instrumentation systems across both the Village and Sanatorium sites. The design ensures operational resilience, safety, and seamless integration with control and telemetry systems. Intelligent MCCs are housed in dedicated kiosks at both the Sanitorium and Village sites to provide power and control for the FINEGUARD™ screens, the SPIROWASH® screenings washing units, the pumping stations and to the MBR stream.

Enhanced supply capacity was required to meet increased load demands and this included new transformers to supply both Village STW and Sanatorium STW.

Two new telemetry outstations were installed and commissioned and a fibre network provides high-speed communication between MCCs, outstations, and control rooms. A new telemetry PLC was manufactured by RSE Control Systems (Blackburn Starling) and in addition, network node boxes were installed for network reliability between Sanatorium STW & Village STW.

[caption id="attachment_25480" align="alignnone" width="1200"] LCPs from RSE Control Systems (Blackburn Starling Ltd) for the new SPIRAC Ltd inlet works - Courtesy of Coffey[/caption]

Village TPS & Outfall PS

Village Transfer Pumping Station was modified to forward all flows of up to 21 l/s to Sanatorium. This required new duty/standby pumps, new iMCC & kiosk, integration of the existing works to accept all flows to Sanatorium and return flows back to the sample chamber for final effluent monitoring.

A key element of the Loggerheads scheme is to match the flow forwarded from the Village TPS to the Sanatorium STW to enable matching flow to be returned to the Village TPS outfall. The initial scope was for the Village TPS iMCC to be integral to the fibre ring for comms interface, however due to challenges and complications over resilience a new approach was adopted. The method used incorporated a new flow matching flow meter and bypass arrangement on the pumped main as it passes through Village STW to the inlet works at Sanatorium STW, where average flows over a 15-minute periods are measured and recorded.

Within the new Village STW, post-MBR treatment there is am outfall pumping station. From here, flows are separated to each respective site with an on-site redesigned solution of constant gravity flow back to Sanatorium STW outfall and a pumped arrangement back to Village TPS outfall. The pumped flow is continually matched to the measured 15-minute average of the flow matching flow meter.

It was necessary to ensure that the pumps were not starved meaning flow matching would be compromised. The original design was adjusted to a complete gravity weir arrangement, ensuring a constantly flooded wet well. This was one of several innovations that ensured the system performed without compromise and the programme pace was kept.

[caption id="attachment_25488" align="alignnone" width="1200"] Village Transfer Pumping Station final effluent monitoring equipment from Servitech International Ltd - Courtesy of Coffey[/caption]

Key challenges & mitigation

Design change from a 2-site to 3-site solution: The project is complex, with the number of inter-site interfaces and many innovative assets and methods used. There was no programme extension to allow for the third location (the reed bed site) and there were land access complications. This complication led Coffey to adopt 7-day working for a number of months and during key phases, 24-hour working to ensure the expanded scope could still be delivered.

Complex logistics: The integration of multiple pumping stations, rising mains, and treatment units required precise coordination and phased commissioning.

Temporary works: The temporary works at Loggerheads were extensive. The vast range has been from trench boxes for laying pipework and rising mains, through to the installation of various large manhole ring pumping stations and, at the works return, where two 3m wide by 6m deep structures were constructed.

Environmental compliance: Meeting stringent discharge permits (0.3 mg/l Total Phosphorus at Village STW) required advanced process control and real-time monitoring. A vast array of commissioning and temporary measures were required to facilitate this operation.

Mechanical, electrical & commissioning works: This element of the project has been significant as shown by the sheer volume of electrical control assets required. The subsequent electrical installation has been met with competency and support by Elsym Installations Ltd to meet the significantly condensed programme. This same intensity has been met by Jones Site Services & Installation for the mechanical requirements on a challenging scheme.

Weather mitigation: The main construction activities took place during a harsh winter when on-site activities were impacted by heavy snow, rainfall and high winds that brought down trees and a powerline; preventing access to Sanatorium during key phases and making cranage a challenge to programme. Cold temperatures impacted concrete activities for the MBR slabs and MCC bases and wet weather provided challenges for the project team during the installation of the 100m pipeline run over the wetlands to the new outfall position at Sanatorium.

[caption id="attachment_25491" align="alignnone" width="1200"] Downed trees and powerlines blocking site access during high winds - Courtesy of Coffey[/caption]

Conclusion

The Loggerheads Sanatorium STW AMP7 Q WFD project serves as a prime example of contemporary wastewater infrastructure implementation. By utilising innovative design, fostering collaboration, and prioritising environmental results, the project aims to provide enduring advantages for both the community and the environment. With completion anticipated in early 2026, it is positioned as a benchmark for upcoming AMP8 initiatives.

In April 2025, the project received the ‘Triumph in face of Adversity’ Award from Severn Trent.