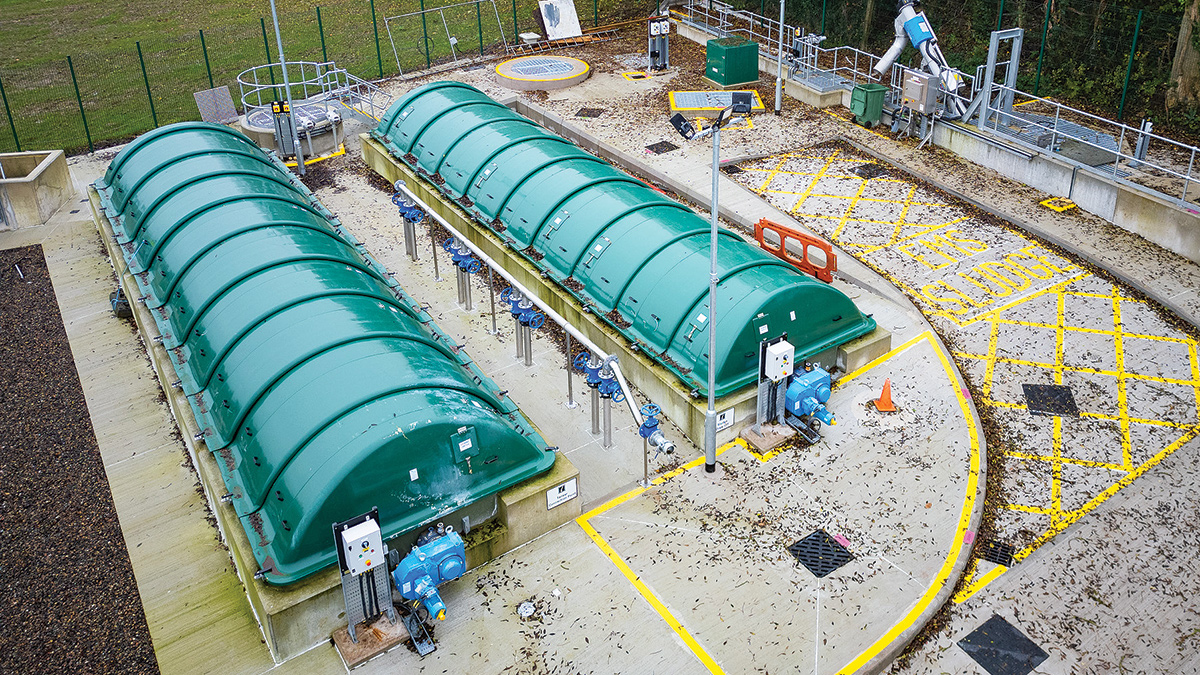

Derrycrin WwTW (2024)

Drone image of the new Derrycrin WwTW - Courtesy of NI Water

Derrycrin Wastewater Treatment Works (WwTW) is situated in a small village in County Tyrone, on the western shores of Lough Neagh, approximately 8 miles east of Cookstown and serves the Ballinderry area. The Ballinderry River is a short distance north of the village and marks the boundary between Counties Tyrone and Derry/Londonderry. The existing works at Derrycrin had been in service for almost 50 years with NI Water having to undertake continued investment in maintenance to achieve discharge compliance levels. Increasing population demands, resulting in greater pressure being exerted on the wastewater treatment works, meant that the existing assets were approaching the end of their design lives and part of the site was prone to flooding.

Introduction

As part of their six-year business plan (Price Control Period 2021-2027) and infrastructure programme, NI Water invested £3.2m to replace Derrycrin WwTW with modern new infrastructure and technology on the existing site footprint that included the installation of state-of-the-art treatment tanks, along with advanced electrical and mechanical systems to provide a robust wastewater treatment solution.

Existing treatment process

Site investigations discovered that the existing Derrycrin treatment process, originally constructed in the 1970s with a design population equivalent of 285, was under capacity to treat the flow and loads from the current population (PE 403).

The existing Derrycrin WwTW located near the Ballinderry River – Courtesy of NI Water

The works comprised of an inlet receiving chamber and rectangular primary settlement tank with a cover, a percolating filter and final settlement (a steel hopper bottomed humus tank). The original tertiary treatment reed bed was decommissioned due to structural failure and removed to create space for a temporary Submerged Aerated Filter (SAF) plant.

While the SAF plant had assisted achieving the final effluent compliance requirement, the plant was ageing overall, and at times of high river levels, the plant was prone to increased risk of flooding. To address these issues and maintain discharge compliance to the Ballinderry River, a new works was required.

The replacement WwTW for Derrycrin has been designed to serve a projected population equivalent of 556, constructed within the confines of the existing NI Water-owned land.

Project drivers

During the planning stage, the main driver for the Derrycrin WwTW project was to provide a new WwTW to cater for development of the surrounding area and ensure compliance with the stricter Northern Ireland Environmental Agency (NIEA) Water Order Consent that will be imposed in future.

The existing works was biologically overloaded and operating beyond its full design hydraulic capacity. Age, condition of the site, increased PE and regulatory requirements were all significant drivers for the project as follows:

- Future growth: To meet the future growth of the local population in the Derrycrin area to 2042 (25-year population growth projection of 556 PE).

- Design flexibility: To provide flexibility in the new design to cater for future extensions or modifications in design flows, loads or consents with minimum disruption.

- Water quality discharge compliance: To deliver environmental improvements through enhanced water quality discharge to the Ballinderry River in accordance with the Water Order Consent standard and Urban Wastewater Treatment Regulations (NI) 2007.

- Environmental impact: A secondary driver was to maximise operational efficiencies, and promote sustainability through reduced energy costs, minimised visual impact, waste, disruption, noise, air quality (odour) and socioeconomic effects.

- Health & safety/structures: Removal of the Health and Safety risks of the failing structures and to ensure all new structures and equipment were above the Q100 flood level to avoid recurrence of flooding at the Derrycrin site.

- Construction phase discharge consent: To phase the construction of the new treatment works on a restricted site whilst keeping the existing process operational to meet all construction phase discharge consent standards for the works duration.

Derrycrin during construction (August 2023) – Courtesy of NI Water

Early contractor involvement

DLJ Water Ltd, a vastly experienced joint venture between Deane Public Works Ltd, Lowry Building & Civil Engineering Ltd and Jacopa Ltd (now Avove Ireland), was appointed by NI Water as the main contractor in February 2021 under an NEC 4 Early Contractor Involvement (ECI) contract.

DLJ Water, specialists in civil, process, and MEICA design and engineering services of water and wastewater treatment plants and infrastructure assets, provided multi-disciplinary design, project and supply chain management for the contract and delivered a full turnkey design and build solution for replacement of Derrycrin WwTW from start to completion.

Process/MEICA designs were provided by treatment process specialist and joint venture partner Jacopa Ltd (now Avove Ireland). AECOM was appointed as civil/structural designers for the scheme on a Professional Services Contract to DLJ Water and worked with joint venture partner Lowry Building and Civil Engineering to finalise the civil design requirements.

The ECI phase allowed DLJ Water to align resources and integrate objectives with NI Water and their project management team from RPS Consulting Engineers at an early stage to benefit delivery. This proactive approach led to enhanced collaboration, innovation, value, efficiency and reduced whole life costs for the project.

Derrycrin WwTW: Supply chain – key participants

- Principal contractor & designer: DLJ Water Ltd

- Jacopa Ltd – now Avove Ireland

- Deane Public Works Ltd

- Lowry Building & Civil Engineering Ltd

- Client project management: RPS Consulting

- Civil/structural designers: AECOM

- MEICA design: Jacopa Ltd – now Avove Ireland

- Temporary works: Cassidy Geotechnical

- Piling contractor: Hamilton Bogie

- Formwork & concrete: McMenamin Construction

- Electrical installation & ICA: Profitec

- Mechanical installation: Bann Mechanical

- Rotating biological contactors: KEE Process Ltd

- Sludge pumps: Xylem Water Solutions

- Water booster set: Dutypoint Ltd

- Concrete: Creagh Concrete

- Precast concrete: FP McCann

- Pipework: Associated Pipeline Products

- MCC: Motrol

- Inlet screen: M&N Electrical & Mechanical (Hydro International Ltd’s UK Wastewater Services)

- Fencing: O’Neill Fencing

Temporary treatment plant used at Derrycrin – Courtesy of DLJ Water Ltd

Civil design

AECOM provided civil, structural and geotechnical design services, including the initial enabling and investigatory works carried out at the ECI stage, as well as the detailed design for construction. They were also employed throughout the construction phase to address any issues.

Civil design included the temporary works to facilitate delivery of the new WwTW, which comprised a primary tank, SAF plant, final settlement tank, sludge holding tank, a pumping station, drainage, interconnecting pipework, ductwork and valve chambers as well as site drainage to meet NI Water’s EMSD requirements.

Other civil design requirements included decommissioning, demolition and removal of existing redundant assets, temporary pipework layout and phasing plan, upgraded vehicular access and entrance from Ballinderry Bridge Road, fencing, signage and lighting.

Key civil design considerations were ensuring that the new structures were elevated relative to the existing site/works to reduce the risk of flooding while maintaining gravity inflows to the WwTW and that formation levels maintained the correct hydraulic profile throughout the site.

Derrycrin WwTW inlet works – Courtesy of DLJ Water Ltd

Regular design and HAZOP meetings were important to develop sequencing of construction works for the major structures and coordinating the positioning of new pipework whilst the existing pipework and services were kept operational. These design workshops gave the integrated project team and NI Water operations staff the opportunity to review the proposed completed works to aid clash detection and advise on design changes or pinch points.

The replacement WwTW was designed on the existing confined site footprint in a phased manner whilst the existing works remained operational. This meant that NI Water didn’t need to make any land purchase to facilitate the plant upgrade.

Process design

Jacopa Ltd (now Avove Ireland) designed a full turnkey replacement process/MEICA plant for Derrycrin considering the best available technology/technique to provide low OPEX costs to serve a projected population of PE 556 within the confines of the existing site boundary.

Following design reviews of the existing WwTW, it was apparent that the available site footprint for a replacement works was limited and maintaining treatment capabilities (in line with current discharge consent standards), while constructing the new works, would prove difficult.

The new rotating biological contactors – Courtesy of NI Water

To overcome the challenge of the restrictive site, Jacopa (now Avove Ireland) identified redundant assets under the client’s portfolio that could be refurbished to form part of a temporary treatment solution. Jacopa engaged their supply chain to fully develop a compact, low maintenance temporary treatment solution that would provide effective treatment during the construction phase. The incoming flows at the existing inlet works were diverted to the temporary treatment plant.

Incoming flows gravitated through a 6mm bar screen which then passed flows to a treatment plant, comprising of an inlet lift pumping station, primary tank, SAF unit with an aeration blower kiosk for biological treatment, a lamella tank downstream for final solids removal and finally, a sludge holding tank.

Construction phasing was kept to a minimum, with a small number of assets from the existing site kept online, specifically the existing final pumping station to lift the flows from the temporary plant to an existing SAF and modified final settlement tanks. The temporary plant was operated and maintained throughout the construction phase by Jacopa/Lowrys.

The new Derrycrin WwTW comprises of a new inlet works (6mm screening) and a 10mm bar screen with improved flow control consisting of a greater than Formula A and FFT overflow discharging to a copasac chamber. Downstream of the inlet, the flow goes into a flow split chamber that is designed to split the flow between two rotating biological contactor (RBC) package plants with provision for a third to be installed in the future.

Flow split chamber – Courtesy of DLJ Water Ltd

The new RBCs provide biological treatment for the removal of organic pollutants, such as ammonia. Each unit comprises loss of rotation sensors, GRP covers, clamps, local control stations, easy-lift lids and end covers, internal auto greaser that had been moved to a hatch (this is for easy replacement by one operator), inlet flow balancing and desludge/scum pump.

Desludging of the sludge tanks within the RBCs is an operation that should be completed every 45 days. The treated effluent from the RBCs flows from the final tank in the RBCs to a joint MCerts chamber. The return liquors pumping station has been designed to protect the watercourse and receive flows from various sources such as the automatic decanted liquors from surface water run-off from potentially contaminated areas; for example, tanker loading areas and inlet screening/skip areas, drainage from process sumps and any general containment.

The new works has been supplied with a new MCC housed within a GRP kiosk including HMI and upgraded telemetry. A new 1000 litre potable wash water booster set and two hose reels in kiosks have been provided and the MCerts chamber measures the flows from the site with temperature and turbidity being measured in the tank also. A flow meter has been installed in the wash water booster set to measure the true usage of water on a wastewater site. All this key information – to assist future decision making – can be tracked and accessed by NI Water through the SCADA network.

MCert chamber – Courtesy of DLJ Water Ltd

Challenges/constraints

DLJ Integrated Project Team overcame some major constraints/challenges through a collaborative team approach to deliver an operationally efficient works including:

- Construction of a new treatment works on a very confined site with difficult terrain.

- Maintaining operation of the existing process for the duration of the works.

- Boundary issue during construction – adjacent land was acquired for the duration of the contract on which the temporary treatment plant was located.

- Phased demolition of existing structures meant the site was even more confined.

- Seeding of RBCs proved difficult as temperatures were low due to the winter period.

- Period of hyper-inflation for material and labour costs during design period.

- Supply chain delays during very uncertain time due to Brexit and volatile markets etc.

The Covid-19 pandemic also interrupted the construction programme, however, DLJ managed all issues with strict site-specific Coronavirus Risk Management Plans and the introduction of an innovative paperless work system to further reduce risks.

In advance of work commencing, joint venture partner Lowry Building and Civil Engineering (LBCE) set up the work compound and Jacopa (now Avove Ireland) installed a temporary treatment plant in lands adjacent to the existing treatment works, located off the Drumenny Road.

Once this had been successfully installed, DLJ were able to begin decommissioning and demolishing the old works in a phased approach. This included mechanical and electrical stripping of some assets which were refurbished by Jacopa and delivered to NI Water before preparation of the site for the new treatment units commenced.

Desludge valves – Courtesy of DLJ Water Ltd

Although space-saving RBCs were part of the design, the additional treatment capacity required a large footprint within the existing NI Water site and there was limited room available for stockpiling spoil or construction materials. As a result, ‘just-in-time’ deliveries were employed.

DLJ Water worked closely with RPS and AECOM at design stage to agree construction and sequencing of all structures to ensure temporary and permanent loadings. Thermal restraint considerations were also considered in the reinforcement design and detailing.

The new infrastructure was elevated to ensure all new structures and equipment were above the Q100 flood level to protect key assets during flooding of the Derrycrin site.

The construction phase at Derrycrin WwTW commenced in November 2022 with a target date for completion of March 2024. Despite all he challenges highlighted, DLJ Water successfully delivered the project on time and to budget.

Public/stakeholder engagement

Collaboration was instilled throughout every aspect of the planning, design and construction phases for the new Derrycrin WwTW. NI Water along with the DLJ Water Team and RPS developed a proactive communications and public relations strategy for the project to ensure that residents and the wider public were aware of the planned installation and to keep the various stakeholders informed of developments with the project.

These included: erection of a detailed information board providing details on the project to passers-by; house calls to nearest residents; circulation of letters; progress briefings for elected representatives; circulation of press releases in the local media and social media announcements.

In addition, continuous stakeholder liaison ensured no stakeholder-driven delays.

NI Water Capital Delivery and Operations personnel pictured with the contract team from DLJ Water and RPS – Courtesy of NI Water

Key benefits/project success

The collaborative working relationship developed between DLJ Water, NI Water, RPS, AECOM and the wider supply chain through the ECI process and subsequent construction phase allowed for greater innovation and successful delivery of a sustainable, state-of-the-art wastewater treatment solution, capable of meeting its stringent consent standard and serving the community for many years.

The solution – designed and constructed by DLJ – was chosen based on its capability, flexibility and reliability to serve the future catchment needs over a 25-year projection horizon ensuring that NI Water targets were met. This impressive scheme has the added benefit of reduced risk to pollution with inclusion of EMS zones and flood levels considered during design and the new treatment process can operate during flood conditions up to 300mm over the Q100 level. Water turbidity can also be monitored remotely to ensure the process is meeting compliance.

Other benefits include providing a safer site: a new vehicular access was provided resulting in reduced risk to NI Water Operatives. This required extensive involvement from the DLJ Water team during the design phase to improve vehicular access to the site. The site is now also designed with space for an additional RBC tank in the future if required.

Sean Milligan, NI Water’s Senior Project Manager commented:

“The investment to replace Derrycrin WwTW with modern new infrastructure will support local development, deliver environmental improvements and ensure NI Water meets EU standards for many years to come.”

The new works was successfully tested, commissioned and handed over to NI Water in June 2024. It is producing excellent results and is comfortably meeting the NIEA final effluent quality standard of 40 mg/l BOD, 60 mg/l suspended solids and 15 mg/l ammonia.

This innovative wastewater treatment solution will accommodate development in the Derrycrin area and is providing increased environmental protection through enhanced water quality for the adjacent Ballinderry River and thus Lough Neagh.

The new Derrycrin WwTW - Courtesy of DLJ Water Ltd