Enpure Ltd

Silicon Carbide Ceramic Membranes (2024)

Cembrane SiC stack - Courtesy of Enpure Ltd

Water companies are facing ever tightening standards, including the treatment of micro-pollutants to almost non-detectable levels in drinking water, very low levels of phosphorus discharge from wastewater treatment, and the requirement to drastically reducing storm overflow spills. The proprietary silicon carbide (SiC) membrane and module is an innovative technology that provides some unique advantages for potable water, wastewater and CSO applications, and helps water companies increase their treatment capacities, reduce costs and reduce their carbon footprint; major drivers for the industry when selecting key process technologies.

Silicon carbide (SiC) ceramic membranes

Silicon carbide ceramic membranes are submerged ultrafiltration flat-plate membranes with a pore size of 0.1 microns. They act as a physical barrier that blocks solids and pathogens, allowing clean water to pass through. The filtration process involves applying a slight vacuum to the membrane surface, pulling water through the membrane while contaminants are retained. After diamond, silicon carbide is the hardest material known to man.

One of the key advantages of SiC membranes, compared to any other organic or alumina ceramic membrane, is their natural hydrophilicity, which attracts water while repelling organic foulants. This reduces membrane fouling, improving filtration efficiency and reducing cleaning requirement. The system uses periodic back pulse washing and air scouring to dislodge accumulated solids, ensuring extended filtration cycle between chemical in place cleaning.

The SiC membranes are also chemically inert, sustaining pH between 2 to 13 and can act as a strong oxidising compound, such as ozone. They are also mechanically robust making them resistant to harsh mechanical and chemical cleanings.

Cembrane SiC membranes, modules, stacks & towers – Courtesy of Enpure Ltd

Key benefits brought by the adoption of the Silicon carbide ceramic membranes are:

- Increased flow: Get up to five times more flow out of existing rapid gravity filters (RGFs) by using Silicon carbide ceramic membranes.

- Low carbon footprint: SiC can be installed in existing tanks available on site, reducing the need to build new concrete structures.

- Consistent water quality: The SiC membranes consistently produce water that meets and exceeds regulatory standards independent of feed water quality.

- Durability & reliability: After multiple years of operation, the SiC membranes show no signs of degradation and no decline of the membrane permeability, vastly improving whole-life cost.

- Operational efficiency: Low maintenance and remote monitoring capabilities minimise operational costs and staffing requirements.

- 25-year whole-life cost: The whole life cost is estimated to be significantly improved compared to the traditional alternative.

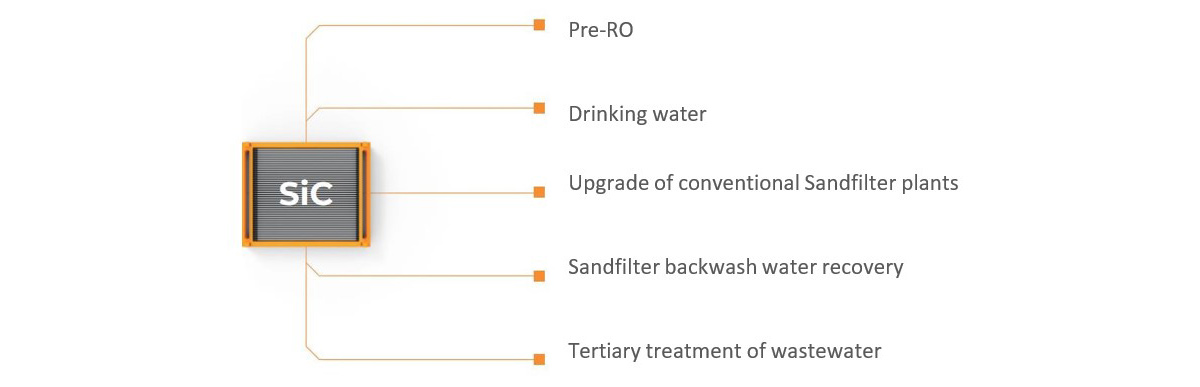

Applications of Cembrane SiC membranes – Courtesy of Enpure Ltd

Cembrane

Cembrane SiC membranes have been installed in over 250 facilities worldwide. The innovative technology provides several advantages against more commonly used organic and inorganic membranes including market-leading flux rates, longevity, robustness and ease of operation. The membranes are manufactured in Denmark and the USA, and have been utilised in more than 70 countries to providing safe drinking water and wastewater treatment.

Case Study: Gothenburg Water Treatment Plant (Sweden)

The Gothenburg Municipal WTP faced challenges reducing manganese levels to comply with regulatory limit of 0.05 mg/l. The plant used a conventional treatment process for treating borehole water by dosing potassium permanganate (KMnO4) to precipitate iron and manganese, followed by sand filtration. While this method effectively removed iron, it struggled to consistently reduce manganese to the required level resulting in non-compliant water.

Additionally, the plant needed to increase its capacity by 50% from 3,500m³/day to 5,200m³/day to meet growing demand. This had to be achieved within the existing filter footprint of 15m2, due to land ownership issues. An upgrade of the existing traditional green sand filters with KMnO4 dosing would have required 42m2 to achieve these requirements, whilst the SiC membrane alternative only required 15m2 and was therefore selected for pilot trials.

(left) Installation of Cembrane SiC stack, (top right) Cembrane SiC stack from above, and (bottom right) SiC membranes have sprinkler cleaning option – Courtesy of Enpure Ltd

Performance confirmed by successful pilot trials: To assess the SiC membranes’ performance, the customer conducted a two-month pilot test between 2015 and 2016. The test evaluated the system’s ability to remove iron and manganese, as well as its durability and maintenance needs. The results were highly positive; manganese concentrations were consistently reduced to below 0.02 mg/l and turbidity was also reduced to less than 0.1 NTU (significantly below the target of 1 NTU). Following the successful pilot, the municipality decided to fully implement the SiC membrane system.

Eighty SiC membrane modules were installed in two filtration tanks, enabling the plant to treat up to 5,200m3/day within the 15m2 footprint. The membranes are installed within modules, each containing 42 flat sheet membranes, providing a total membrane surface area of 6.85m2 per module. These membrane modules are stacked in towers, with up to 15 modules per tower. Each tower includes a top permeate module, which collects the filtered water, and a bottom diffuser module, which distributes air for cleaning purposes. For Gothenburg, eight towers comprising ten filtration modules were installed in two of the existing filter structures.

Conclusions: Three years after installation, the SiC membrane system has continued to perform exceptionally well. A full inspection revealed no signs of decline in membrane permeability or structural damage, and the plant consistently delivers high-quality drinking water with the following parameters being achieved:

-

- Flows: 50% increase from 3,500m³/day to 5,200m³/day.

- Manganese: <0.02 mg/l (target <0.05 mg/l).

- Iron: Non-detectable (target <0.05 mg/l).

- Turbidity: <0.1 NTU (target <1 NTU).

- Recovery rate improvement: from 80% to 99%.

Conclusion

Cembrane SiC membranes give water companies the opportunity to expand and improve their treatment facilities at low additional cost and carbon footprint. Cembrane and Enpure are both part of SKion Water, who have a diverse portfolio of innovative companies providing technologies for water and wastewater treatment to municipal and industrial sectors. Enpure Ltd will deliver Cembrane SiC membranes throughout the UK.