Eela WTW (2025)

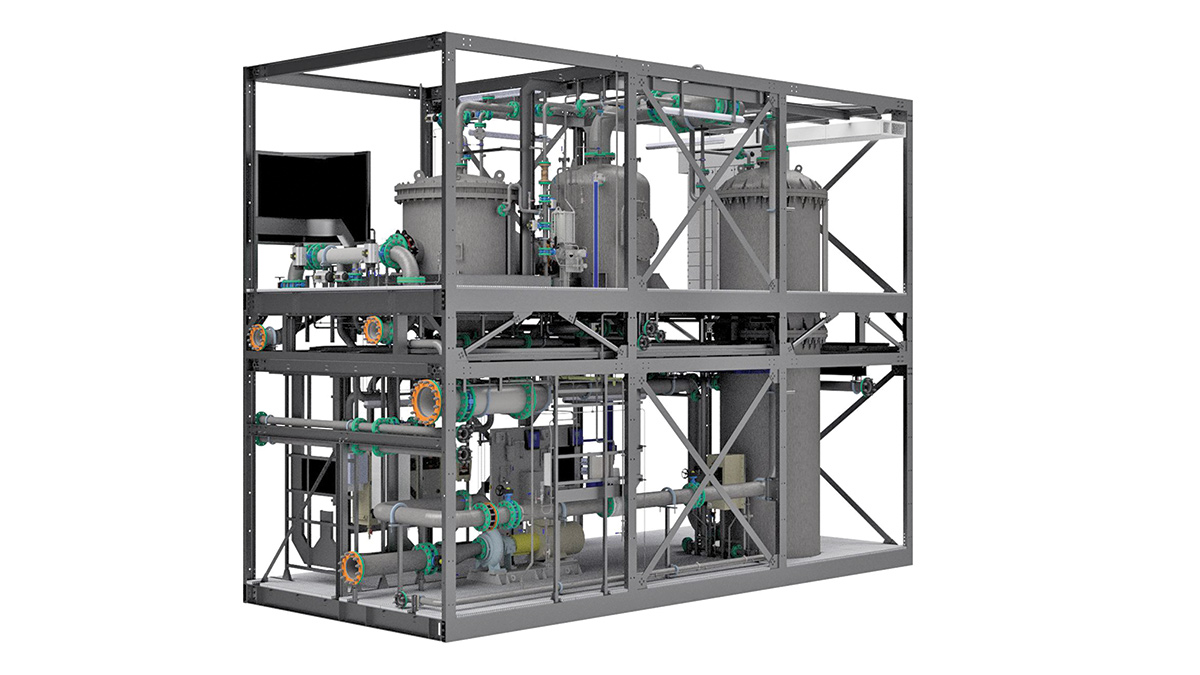

Modular and productised off-site build approach in workshop conditions - Courtesy of RSE

Eela Water Treatment Works (WTW) was built in 1978 near Ollaberry on the mainland of Shetland, and it currently supplies up to 4.3Ml/d to around 5,400 people and the Sullum Voe Oil Terminal. The area supplied by Eela has a history of microbiological and discolouration exceedances of regulatory standards in the final water. Incapacities exist in the clarifiers where maintenance and efficient sludge removal cannot be performed. Discolouration issues within the final water at Eela, and in its associated distribution zone, are linked to seasonal peaks in raw water manganese. RSE (Ross-shire Engineering) was awarded the upgrade at Eela WTW to mitigate the 29 residual risks at customers’ taps within the Drinking Water Safety Plan (DWSP) that meet the threshold for action.

Redefining DfMA – Design for Modular Assembly

To maximise efficiency and minimise disruption, RSE is employing an off-site modular build strategy. This approach enables progress on-site, with the civils team moving forward with earthworks, slabs, underground pipework, etc, at the same time as they push forward in their cutting-edge manufacturing facility. This parallel workflow significantly accelerates the overall programme.

The delivery of over 40 Transportable Treatment Units (TTUs) to Shetland demands meticulous logistical planning and seamless coordination between RSE, the client, and logistics partners. All the TTUs will first be mobilised to the Port of Cromarty Firth in Invergordon, where they will be securely loaded and fastened onto a vessel. After a 24-48 hour sea journey, the units will then be off-loaded at the Sullum Voe Oil Terminal and transported by road to the project site. This operation represents one of the most remote and logistically complex modular water treatment deployments in the UK, delivered at an unprecedented pace.

Trusted water technology solutions

As a trusted provider of advanced water treatment technology solutions, RSE are undertaking Principal Designer and Principal Contractor responsibilities on the project; delivering the full scope of civil engineering works, process engineering, MEICA, filtration, chemical dosing, clear water storage systems, and commissioning of the new 5.7Ml/d ceramic membrane treatment plant, to replace the existing 1978 facility.

Eela WTW TTUs fabricated in modules before disassembly and transportation to site – Courtesy of RSE

The new works will utilise PWNT’s C37 CeraMac® ceramic membrane system, offering enhanced resilience and water quality performance to address long-standing issues with microbiological and discolouration exceedances.

Enabling all involved to clearly visualise the delivery strategy was paramount, meaning the in-house RSE BIM team used the Autodesk Construction Cloud Federated Model to prepare a step-by-step 4D animation of the delivery and rebuilding of the plant.

Eela WTW: Supply chain: key participants

- Designer & contractor: RSE (Ross-shire Engineering)

- Ceramic membranes: PWNT

- Logistics & specialist transportation: GF Job

- Shipping: Marlin Abrams

- Groundworks: Tulloch Developments

- Civils: T-Gray Groundworks

- Formwork & precast concrete: DB Stuart Ltd

- Process pumps: Sulzer Pumps Wastewater Ltd

- Compressors: Kerr Compressors

- Chemical dosing lines: FT Water Treatment

- Chemical dosing pumps: Prominent Fluid Controls (UK) Ltd

- Chemical dosing pipework: Georg Fischer

- Pipework materials: Cleveland Steel & Tubes Ltd

- Pipework materials: DH Stainless

- MCCs: GPS Group

- Chemical tank bund gratings: Relinea

- Valves & pneumatic actuators: Socla UK

- Static mixers: Statiflo International

- Pneumatic control banks: Burkert Fluid Control Systems

- Pressure instruments: Trafag UK

- Quality instruments (pH/ORP): Endress+Hauser Group

- Quality instruments (turbidity): Hach UK

- Quality instruments: Process Instruments (UK) Ltd

- Process flow meters & pressure instruments: IFM Electronics

- Process flow meters & level transducers: Siemens

- Large diameter flanges: JR Whitehead 2000 Ltd (flanges.co.uk)

- Instrument pipework: Mapress

- Instrument pipework: Hylok

- HV switches: Schneider Electric Ltd

- HVAC: Air Technology Systems

- Safety showers/eyebaths: Aqua Safety Showers International Ltd

Treatment works process

Raw water flows to the WTW primarily via gravity feed from the Roer Water Reservoir, with supplementary volume provided through pumped abstraction from the Eela Water Reservoir. These two sources are blended in an external mixing tank to ensure consistent influent quality prior to treatment. The blended raw water stream is then introduced into the treatment train, initiating a multi-stage purification process. The treatment sequence involves:

- Pre-filtration to remove coarse particulates.

- Automated chemical dosing for pH adjustment and coagulation enhancement.

- Coagulation and flocculation to aggregate suspended solids.

- Membrane filtration for fine particulate and microbial removal.

- Limestone contactor for remineralisation and pH stabilisation.

- On-site electro-chlorination for final disinfection and residual protection.

Eela WTW is engineered with over 70 strategically distributed sampling points, integrated into the Supervisory Control and Data Acquisition (SCADA) system. These sampling nodes provide real-time water quality monitoring across all critical control points. As part of the software and commissioning scope, the system includes automated fault detection protocols. Any deviation from predefined quality thresholds at these sampling points triggers an immediate diversion of affected water to a dedicated waste handling system. This diverted water is retained for controlled recycling or safe disposal, ensuring compliance with regulatory standards and operational integrity.

Products & innovations

RSE has developed a productised modular solution utilising PWNT’s C37 CeraMac® ceramic membrane technology; the m-CTU®, and the required wrap-around solutions including m-BWU®, m-CIP®, m-NAC® and m-NAL®. This innovative approach to standardisation creates consistency in design and quality, allowing significant reductions in programme, costs, and carbon, ensuring significant benefits over bespoke site builds. Each product is engineered for scalable deployment, accommodating site-specific requirements with minimal additional design work.

Workshop environment testing of pre-designed TTUs – Courtesy of RSE

The m-CTU® suite caters for plant capacities ranging from 4Ml/d to 70Ml/d to be achieved while ensuring seamless integration to the other modular assemblies. Repeatability of product offerings allow for a reduction in the number of critical spares across various sites, simplifying maintenance and repairs, in turn minimising disruption to operations. RSE is continuing to develop a range of productised water treatment solutions creating a standard, Design for Modular Assembly, plug-and-play type approach, minimising on-site disruption whilst ensuring a robust technical solution in line with current industry standards.

At Eela WTW, the adoption of the innovative off-site build approach has significantly enhanced the overall quality and efficiency of project delivery. While factory-built systems already offer a high standard of quality, the use of repeatable, pre-designed products further elevates this by enabling teams to quickly identify discrepancies through their familiarity with design packs and past projects. A key advantage of this method is the ability to carry out commissioning activities within the workshop environment. This allows early detection of defective or damaged components, thereby reducing the risk of rework and minimising delays during on-site commissioning.

Health and safety outcomes have also improved, thanks to the project teams’ growing familiarity with the product and the continuous refinement of designs to eliminate potential hazards. Furthermore, the transition from welded structures to bolted frames has enabled a 34.25% reduction in embodied carbon across our Modular Ceramic Treatment Unit (m-CTU®) product range, achieved through the use of green steel, recycled glass reinforced plastic grating, and other sustainable materials.

This modular, productised approach also boosts design office productivity by incorporating pre-designed “Lego block” components into the design process, with any additional design work tailored to complement these standard elements. Where feasible, new design areas are also productised to further streamline future builds.

CAD render of m-CTU® (ceramic ultrafiltration module) – Courtesy of RSE

Progress

The key programme dates for the Eela WTW project are as follows:

- January 2024: Early procurement contract award.

- January 2025: Construction contract award.

- January 2025: Off-site fabrication start.

- February 2025: Off-site assembly start.

- August 2025: First modular unit delivered to site.

- October 2025: Final modular unit delivery to site.

- January 2026: Commissioning start.

RSE remain on programme for the delivery of Eela WTW, with ship out and on-site installation scheduled to commence in August 2025 and the expected commissioning phase to start in January 2026.

Recognition through innovation: The King’s Award

In June 2025, RSE was honoured to receive the King’s Award for Enterprise, the highest accolade available to UK businesses, in recognition of our contribution to innovation in the water industry. The award specifically acknowledged the ground-breaking work behind the off-site build approach and development of the modular m-CTU® product; both of which were instrumental to the successful delivery of the Eela WTW project.

The upgrade at Eela WTW exemplifies the innovation that the award celebrates by embracing Design for Modular Assembly (DfMA) fabrication methods and integrating advanced water treatment processes into standardised products, the project delivered significant gains in efficiency, quality, and sustainability. The projects’s success is a testament to why RSE was honoured with the King’s Award for Enterprise, showcasing how an innovative mindset and dynamic teams can set new standards for project delivery and transform the water industry.

Senior coordinators and apprentices working on the fabrication of the modular ceramic membrane plant for Eela WTW - Courtesy of RSE