Sandown WSW: Flood Resilience (2025)

Raw water lagoon - Courtesy of Trant Engineering

Sandown Water Supply Works (WSW) supplies water to the Isle of Wight. The works treats water from the River Yar, which provides a steady supply and allows the rate of extraction from the boreholes across the island to be reduced in winter so the groundwater levels can recover. The works is situated in the River Yar flood plain and is at risk from high water levels during a tidal event.

The primary impact of such an event would be failure of site controls, treatment process and delivery to the distribution network via service reservoirs. In 2024, following a study of existing site assets, Southern Water were issued with a regulatory date to review current flood risk and remedial works to ensure suitable resilience. It was decided that some critical areas require upgrades to help prevent issues and improve protection.

Project scope

The scope of the works included:

- Raising of the walls of the raw water lagoon.

- Installation of footpaths and handrailing around the raw water lagoon.

- Installation of flood barriers to MCC kiosks.

- Installation of non-return valves on raw water lagoon overflow and bypass pipework.

- Seal cable trough penetrations into Microfloc building.

- Low section of the existing WWR lagoon perimeter wall raised.

The upgrade ensures that assets are protected during a 1-in-30-year storm event (where flooding could reach up to 2.7mAOD) and will allow the works to return to service quickly and smoothly after a flood. The Drinking Water Inspectorate set a regulatory date of February 2025 for completion of the upgrade works. Southern Water selected Trant Engineering as Principal Designer and Contractor with responsibility for the design and construction.

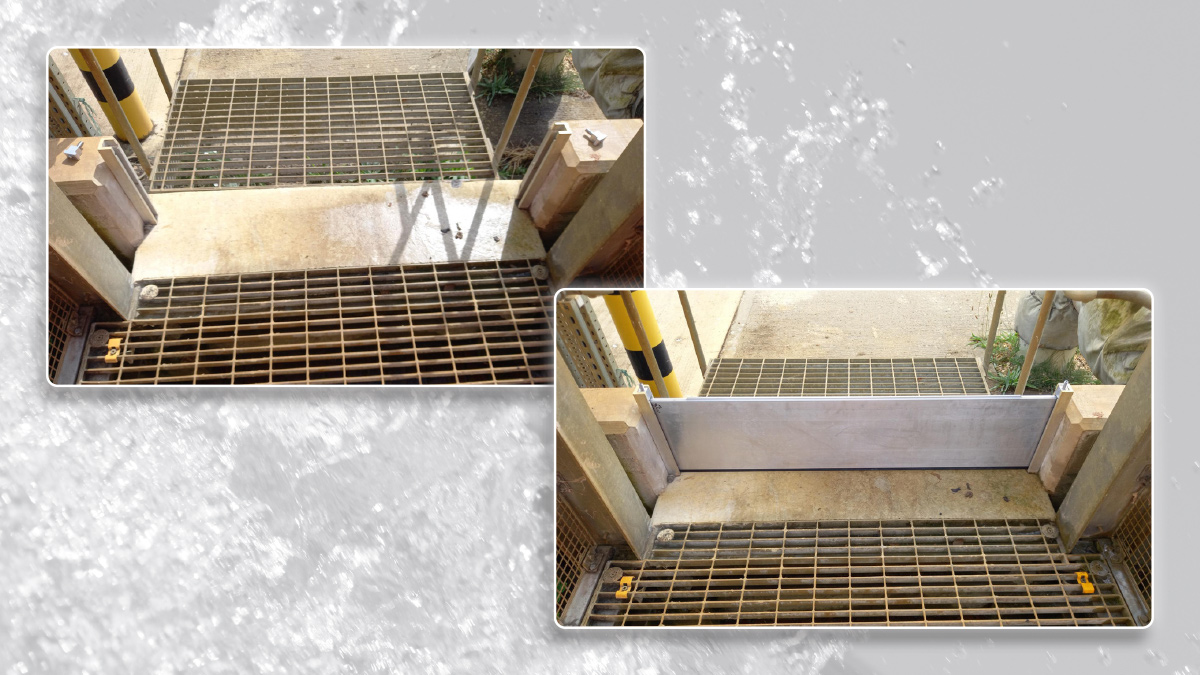

(left) Removable flood barriers deployed and removed at MCC Kiosk entry and (right) deployed over vents – Courtesy of Trant Engineering

Sandown WSW Flood Resilience Project: Supply chain – key participants

- Principal contractor: Trant Engineering

- Flood defence design: Pritchard Wilmott

- M&E: FW Marsh (Electrical and Mechanical) Ltd

- Civils: WH Brading & Son Ltd

- Flood barriers: Flood Protection Solutions Ltd

- Duct sealing: MM Engineering

- Steelwork: Semco UK

- Steelwork: Toomers Ltd

- Magflow meters: Siemens

- Duck bill non-return valves: Tideflex

The works

Using masonry construction, Trant increased the height of the wall to protect the inlet raw water storage reservoir and installed a new footpath with handrailing to provide access to the entire perimeter. The raw water lagoon gantries were fitted with removable flood barriers of a simple design from lightweight materials that can be easily and rapidly deployed by a single operative. Non-return valves were installed on raw water lagoon overflow within the adjacent river and bypass pipework to prevent backflow of flood water into the reservoir.

The motor control centre (MCC) kiosks are now protected by barriers held by removable posts over doors and entry ways. The lightweight barriers can be easily installed into position and fixed down with compression grub screws, allowing for quick deployment when required, as well as easy removal when no longer needed. All removable items are conveniently stored in a purpose-built storage unit.

Gantry access showing the removable flood barriers both deployed and removed – Courtesy of Trant Engineering

Cable entry troughs to the building housing a Microfloc treatment plant and contact tank were sealed with re-entry resin to prevent water access. This better protects the assets within the buildings reducing the chance of failure in a flood event, ensuring site can continue operating throughout extreme weather circumstances. Even in the event of a site shut down due to issues elsewhere, this protective measure will assist with restarting of site whilst preventing additional failures.

Project completion

Works began in 2024 on the live site, which continued operations without interruption to supply. The key date was the DWI Regulatory date at the end of February 2025, which was successfully met. And all flood works, including remedial works, were handed over to Southern Water on 27 March 2025.

One of the duckbill non-return valves - Courtesy of Trant Engineering