Campbeltown Flood Protection Scheme (2024)

View across Burnside Square, Campbeltown - Courtesy of DAWSON-WAM Ltd

Campbeltown has experienced flooding over many years, which has affected residential properties, businesses, roads, and community life in general. In June 2022, construction started on a 24-month, £16m scheme, (co-funded 80% by the Scottish Government and 20% by Argyll and Bute Council) under the Flood Risk Management (Scotland) Act 2009 where the council is responsible for developing sustainable flood management solutions. DAWSON-WAM Ltd was appointed as principal contractor, with AECOM employed by the council to provide design and project management support throughout the contract.

Flooding sources

The existing sewer network system in the Burnside and Meadows areas could not cope with increasing amounts of surface water. The sewer network combined surface water with sewage water from households. When the system was overwhelmed during periods of heavy rain, fouled water backed up out of the system and flooded streets and premises.

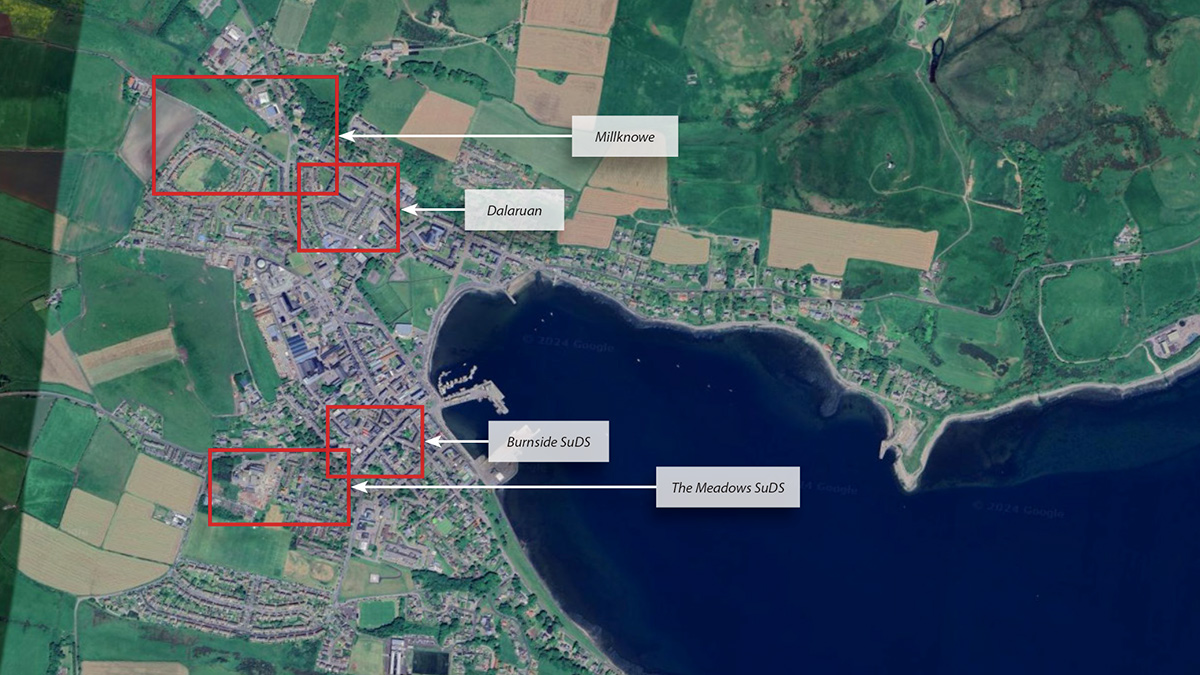

On the outskirts of the town is the Millknowe Burn which, due to several steep catchments, is the most dominant flood source in Campbeltown. Flows from the Balgreggan Burn also caused overtopping during extreme events at the Dalaruan culvert intake and resulted in overland flows and flooding in the town.

Google Earth image showing Campbeltown FPS site locations

Scope of works

The scope of the scheme was to reduce the risk of flooding from the Millknowe and Balgreggan Burns and from localised surface water in Campbeltown. The project was rolled out over four working areas:

- Millknowe flood storage reservoir.

- Dalaruan culvert.

- The Meadown SuDS.

- Burnside Square.

Millknowe Flood Storage Reservoir

Millknowe Field is located beside the watercourse channel, which acts as a catchment area for rainwater. It floods onto nearby roads and streets; particularly the main A83 trunk road which provides the primary access into the town. There are two block of flats beside the field, built essentially on the same floodplain that is prone to flooding during heavy rainfall when the watercourse and culvert cannot cope with the flow of water.

Snipefield Industrial Estate is located on the northern side of the watercourse channel, which is home to many local businesses. This was also prone to flooding from the field during heavy rainfall events.

The scope of works at Millknowe included:

- Construction of a flood storage reservoir in Millknowe field to provide temporary flood water storage within the watercourse channel during high rainfall events.

- Realignment of the watercourse channel along a new sheet piled wall.

- Installation of over 500m of new back of wall drainage ranging in diameter from 225mm to 600mm and new outfalls with flap valves through the new flood wall.

Installation of AZ sheet piled wall with TM22 piling rig to form reservoir – Courtesy of DAWSON-WAM Ltd

Flood storage reservoir

The reservoir was constructed in line with the Reservoir (Scotland) Act 2011 and comprised a 125m long AZ19-700 sheet piled wall encased in a 2.6m (average height) earth embankment dam and concrete spillway. A 325m AZ20-700 sheet piled flood wall formed the enclosed dam structure and provided flood protection to Snipefield Industrial Estate. The sheet piles were driven into cohesive soils and ranged between 6m to 9.5m in length. A new concrete culvert passing through the dam with headwall and orifice plate was constructed to throttle the flows. The exposed piles were capped off with a precast concrete coping.

To facilitate the installation of the 450m of steel sheet pile wall, a 6m wide x 600mm deep stone temporary piling platform was installed to support the 90T ABI TM22 piling rig.

Where space allowed, the piling platform was constructed in Snipefield Industrial Estate to the north of the watercourse. This minimised the length of the watercourse that was required to be culverted and reduced the impact on agricultural soils and the watercourse, and reduced the amount of imported stone required.

DAWSON WAM’s in-house heavy-duty steel mats were utilised which further reduced the amount of imported material for the piling platform. Three temporary bridge culvert crossings were constructed using the mats which allowed full access along the length of the wall during construction.

Temporary bridge crossing watercourse using DAWSON-WAM Ltd’s heavy duty steel mats – Courtesy of DAWSON-WAM Ltd

The sheet piles were purchased from Arcelor Mittal in Luxembourg, and were stored in DAWSON-WAM Ltd’s yard in Bedfordshire. The piles clutches were sealed using Biguma SV and were delivered to site in a just-in-time basis throughout the project.

DAWSON-WAM Ltd used an ABI TM22 piling rig to complete the piling installation works. This rig with its powerful 36VV vibro hammer is the most powerful leader rig mounted vibro in the UK and Europe. Interchangeable attachments were mobilised, including the preaugering with advanced cased CFA and the HydroPress system, which allowed increased production and mitigated risks where unforeseen ground conditions were encountered.

Service crossings

The new sheet piled wall installation required to perpendicularly cross a 225mm asbestos cement Scottish watermain and a high voltage (HV) Scottish Power cable. These two services were critical to the town infrastructure and any disruption or shutdowns would have caused a extensive disruption to the town’s residents.

Traditionally these services would have to be diverted through the wall in a phased approach, resulting in inefficiencies and several shutdowns on the services. Through DAWSON-WAM Ltd’s in-house expertise and utilising its specialist vibrationless HydroPress piling equipment, installation of the piles adjacent to the utilities was successfully achieved without diverting the services. This involved early liaison and working closely with the designer and utility providers, undertaking trial pits to ascertain the ground conditions, installation of vibration monitors on the services to highlight vibration levels during install and agreeing a short shut down of the services during pile install.

Earth embankment

The earth embankment at Millknowe consisted of an up to 4m high 125m long embankment with a 21m in situ reinforced concrete spillway. The embankment footprint was excavated removing 3000t of topsoil, 6000T of peat and associated soft soils to form the earth embankment foundation on alluvial or raised beach deposits with a Cu value greater than 40Kpa.

To consolidate the formation level prior to construction, trial pits were excavated along the footprint of the structure and with the aid of a shear vein test, the employer-appointed Reservoir Construction Engineer witnessed and approved the formation levels on site.

2,600t of locally sourced Class 6C compacted in accordance with CESWI 7th Edition in a 500mm deep layer formed the foundation of the embankment. The main body of the embankment was constructed using 5,800t of compacted Class 1A granular fill, with the maximum embankment height of 4m with sloped of 1V:3H. Class 6N granular material was used to segregate the Class 6C and Class 1A material around the piles.

The embankment was capped with a 300mm layer of site won screened topsoil and reinforced with coir matting and seeded. Associate embankment toe drainage and a hardstand access road was provided for future maintenance access.

Realigned burn along sheet piled wall reinforced with coir matting – Courtesy of DAWSON-WAM Ltd

Dalaruan culvert

270m of the existing Dalaruan storm water culvert required upgrading from the Millknowe flood storage reservoir intake to downstream of Dalaruan Street intake. This online upgrade would convey flows and provide additional inline storage from the Millknowe reservoir and prevent overtopping flows from the Balgreggan Burn during extreme rain events.

The exemplary design proposed the install of concrete culverts however as Dalaruan Street is straddled by terraced houses with listed boundary walls and with a congested mix of utilities of various eras, it was decided from an early stage in the contract a detailed survey be undertaken including trial digs to ascertain existing utility positions. This work proved prudent as a design change was requested to provide a more buildable solution while managing live flows and to avoid extensive service diversions.

The contractor and designer worked collaboratively, and through engaging with the supply chain and by re-modelling validation, the section of culvert was changed to a twin line using AquaSpira pipes. This solution provided a bespoke steel reinforced twin piped culvert which had both health and safety and constructability benefits and prevented extensive costly service diversions.

In total, 110m of twin 900mm and 45m of twin 675mm pipes were installed including 115m of single 675mm pipe to form the new culvert. AquaSpira’s prefabricated manhole units were used, which proved to be considerably easier to install compared to the traditional concrete manhole rings, and benefited the management of the existing live storm flows, as well as a faster build time.

During the 6-month construction phase of the Dalaruan culverts, as the majority of the works required the closure of the Dalaruan Road, an extensive public relations exercise was undertaken prior to works commencing. Following the extensive liaison, a phased programme of work plan was developed which merged the phasing of the works and the concerns raised from the public events.

This plan was then shared prior to construction commencing and was supplemented with a full-time public liaison officer, this resulted in the successful installation of the replacement culvert in time to take the first storm flows.

(left) Installation of twin 675mm diameter AquaSpira pipes and (right) installation of prefabricated manholes – Courtesy of DAWSON-WAM Ltd

The Meadown SuDS

The Meadows catchment area consisted of an existing, out of date, undersized combined sewer network system that during periods of heavy rainfall events caused out of sewer flooding to occur. This, combined with the existing culverts in the Witchburn and Meadows areas that could not convey sufficient volume of stormwater, resulted in regular localised flooding events.

The solution was to provide 6500m2 of storm separation on the existing road network by installing over 1.2km of new storm pipe ranging in diameter from 150mm to 375mm and connecting over 65 existing storm gullies to the new infrastructure. This new pipe network conveyed storm flows to three new detention basins with a total capacity of 1500m3 to temporarily attenuate surface water runoff before releasing it back into the existing Witchburn Culvert system. The shallow detention basins were constructed in existing green spaces with 1:4 slopes with a 3D cellular confinement system installed on the basin slopes to improve soil stabilisation and control erosion.

Flows from the basins are retained by flow control manholes fitted with Storm Brake valves, which limit storm flows to between 4.5 l/s and 7.7 l/s into the culverts in a more forgiving manner.

Biodiversity within the detentions basins was enhanced by planting a wet meadows mix plant and a combination of birch and willow trees surrounding them. Due to the poor quality of the existing road surfacing, new full width reinstatement was undertaken to all roads that acquired new storm drainage significantly enhancing the whole road network.

Reinstated detention basis at Meadows – Courtesy of DAWSON-WAM Ltd

Burnside Square

A new underground geocellular attenuation tank in Burnside Square was constructed to temporarily store and attenuate 540m3 of surface water runoff from 1.6km newly constructed storm separation pipework in the Witchburn and Burnside areas during high rainfall events before releasing it back into the existing culvert network.

As Burnside Square was at the heart of the town, it posed several construction risks none less than excavating near three-storey properties that dated back to the 1700s with stone foundations, while having to maintain safe access to the business and residential premises contained within.

Due to the level of disruption anticipated in this area, the contract had restricted these works to be completed during the winter months and required it to be re-opened for public use by June 2023 in time for the peak tourist season.

Following the completion of a detailed ground investigation, it identified that there was largely granular materials withing the dig area for the new attenuation structure, with a water strike just at dig level. Due to the above mentioned buildability concerns, a battered excavation solution posed many risks, therefore a secant piled box cofferdam solution was opted for which would act as both permanent and temporary works for the tank.

DAWSON-WAM Ltd utilised its in-house cased CFA piling rig to install the 300 (No.) 450mm diameter secant piled cofferdam, with its vibrationless installation method eliminating the risk of vibration on the surrounding properties, with this solution the space around the perimeter of the site was able to be maximized, resulting in sufficient space for pedestrians to access the premises safely during the construction period.

(left) Secant pile installation using cased CFA at Burnside Square, and (right) Geocell attenuation tank at Burnside Square prior to backfilling – Courtesy of DAWSON-WAM Ltd

Upon the excavation of the 2700T of granular material, the area was bedded with single-sized rounded stone which provided the base for Polypipe’s lightweight Polystorm-R crates. The crates were delivered in articulated lorries and were built in situ and wrapped in a welded impermeable liner and geotextile protection fleece.

Inspection chambers and a manifold pipe arrangement was formed to enable the filling, emptying, and maintenance of the tank. To prevent overloading of the tank in the temporary condition, the tank was backfilled with imported aggregate in a sequence using small plant, a 100mm layer of Bitmac then formed the foundation for the 900m2 of new block paving.

As the existing square was predominately used for car parking, the council grasped the opportunity to reinstate the area into a multi-functional space that could be utilised for community events as well as serving as daily parking.As part of the final reinstatement, over 52 new bollards and an array of new street furniture and planters were installed.

Supply chain: key participants

- Main contractor: DAWSON-WAM Ltd

- Project management & client design: AECOM

- Materials testing: MATtest Limited

- Culvert pipes/chambers & twin pipe culvert (Dalaruan Street): Aquaspira Ltd

- Sheet piles: Arcelor Mittal

- Attenuation tank installation: Hydro Water Management Solutions Ltd

- Precast concrete: FP McCann

- Civil contractors: McFadyen’s Contracts Campbeltown

- Landscaping: MW Groundworks

- Attenuation tank drainage crates: Polypipe Civils & Green Urbanisation

- Drainage & ducting materials: Huws Gray | Jewson

- Transformers: Wilson Power Solutions Ltd

Storm separation pipework installation at Witchburn – Courtesy of DAWSON-WAM Ltd

Community benefits

It was obvious from inception that, engineering challenges aside, one of the key challenges for the project team would be constructing the works within this rural town in Scotland which would not have previously witnessed a construction project on this scale.

Effective consultation with stakeholders, which included road users, local businesses, residents, the general public and affected landowners, would be key to the minimising disruption and to the project’s successful delivery.

Several pre-construction pop-up events were held locally with the residents, businesses and stakeholders. Consultations were carried out through Argyll and Bute Council’s internal communications team and monthly newsletters were issued through the portal giving updates on construction progress and programme of works and queries were managed through the site-specific e-mail and emergency contact number. Public drop-in meetings and letter drops were undertaken in advance of entering a new area of works.

A project of this size and complexity will always have a significant local impact and it was important that the project team endeavoured to engage with and, for the duration of the project, be part of the community.

Realigned burn along sheet piled wall reinforced with coir matting – Courtesy of DAWSON-WAM Ltd

Initiatives to promote community engagement included:

- Visits from the construction engineering team to Dalintober and Drumlemble primary school, educating the children on the dangers of construction sites.

- Donations of PPE waterproofs to the school to help support their learning and exploration group.

- Donation of a ‘LEGO education spike prime Set’ to help engage STEM learning and problem-solving skills.

- Donation of Ukuleles to the local kids’ music group.

- Local charity donations including a donation to the Kintyre Sea Sports charity to purchase new equipment to aid in the training and development of the local disadvantaged children in water activities.

- Donation of 6T of topsoil to Campbeltown Climate Action for use in their community garden.

- Voluntary repairs to the Campbeltown youth football team goal posts and changing facilities access paving prior to a kid’s football tournament.

- Supply and installation of a bicycle rack in Burnside Square.

The most significant community benefit was the employment of a local sub-contractor to undertake much of the construction works. This provided and supported employment to the residents of Campbeltown and supported the local businesses as the money stayed in the community.

Reinstated Burnside Square – Courtesy of DAWSON-WAM Ltd

Conclusion

In Autumn 2023 during two periods of heavy rainfall, the Millknowe Reservoir, the Meadows detention basins and the Burnside attenuation tank protected the town from flooding and reduced the load onto the wastewater network.

The successful delivery of the Campbeltown Flood Scheme was a brilliant example of collaboration between the contractor, client, designers, and the local community; ultimately resulting in the success of the project as well as providing an asset that will efficiently protect the town and its residents for years to come.