Newthorpe STW (2025)

Newthorpe STW aerial view (July 2025) - Courtesy of Mott MacDonald Bentley

Newthorpe Sewage Treatment Works, located in the Erewash Valley of Nottinghamshire, recently underwent a major expansion to address increasing demand and regional growth. The upgraded facility now provides double its original capacity, increasing treatment from 324 l/s and 41,000 population equivalent (PE) to 649 l/s and 100,000 PE, in order to accommodate flows from the Heanor Milnhay catchment area. The project also included the construction of a 2.5 km dual-rising main connecting Newthorpe to Heanor Milnhay STW in Derbyshire, a dual-stream site which had reached its operational limits and could not meet projected population requirements at its original location. Upon completion, the Heanor Milnhay site has been decommissioned and re-purposed to deliver stormwater storage exceeding three times its previous capacity; considerably reducing the number of spills to river.

Project objectives

With the completion of the project, the following project objectives were achieved:

- Effluent phosphorus levels were reduced from 2 mg/l to below 0.2 mg/l.

- Plant operational and maintenance costs were cut by merging two treatment works and adopting less chemical-intensive processes.

- Untreated sewage spills were minimised by expanding stormwater storage at Heanor from 2,200m3 to 7,000m3, with all storm flows receiving physical screening and settlement.

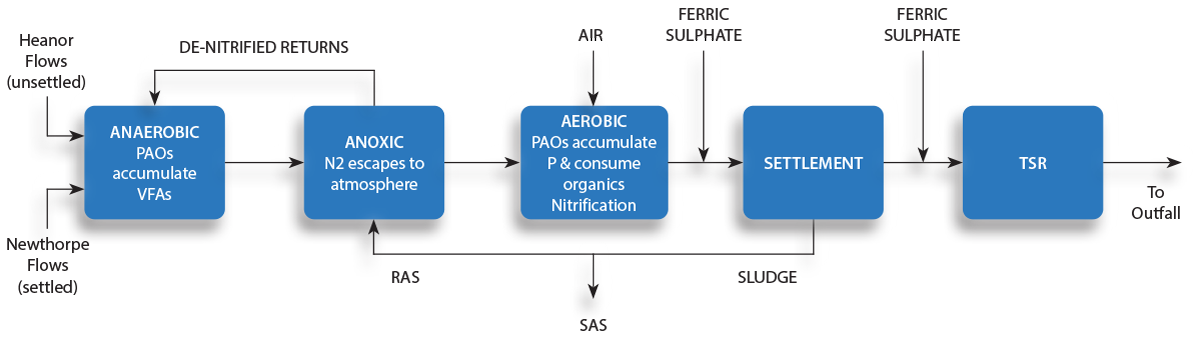

Process diagram – Courtesy of Mott MacDonald Bentley

These project objectives are fully aligned with today’s environmental and economic priorities; promoting both care for the environment and financial responsibility. By improving nutrient removal, optimising operational costs, and significantly limiting untreated sewage discharges, the expansion enhances the protection of local waterways and supports sustainable regional growth, ultimately benefiting the community and the wider environment.

Preliminary & primary treatment

Following the expansion, Newthorpe and Heanor flows now undergo separate preliminary and primary treatment streams before combining at the secondary treatment stage. Flows from the Newthorpe catchment area enter the existing inlet facility, which retains its current configuration, with upgrades limited to mechanical equipment.

Archimedes screw pumps raise the inflow to an elevated inlet works structure housing new fine screens engineered to capture at least 80% of solids greater than 6mm in size. Downstream of these screens, a new detritor facilitates the removal of grit and inorganic materials such as sand, thereby protecting mechanical components from potential damage.

Subsequently, the sewage proceeds to primary treatment, where gravitational settling in two existing primary settlement tanks achieves initial physical separation of fine particles. The effluent from these tanks, which previously fed into secondary treatment via trickling filters and humus tanks, is now redirected to the expanded works.

On the other hand, flows from the Heanor catchment are pumped 2.5km to a newly constructed inlet works at Newthorpe. This facility, incorporates 2D 6mm screens from The Longwood Engineering Company Ltd, and a 4.5m detritor from Tuke and Bell Ltd. Following grit removal, these flows merge (without undergoing prior settlement) with Newthorpe flows. Maintaining the unsettled state of Heanor flows is essential to ensure optimal process loading.

Heanor flows inlet works at Newthorpe STW – Courtesy of Mott MacDonald Bentley

Secondary treatment

Biological treatment occurs at the secondary stage, targeting reduction of specific parameters, including phosphorus, ammonia, iron, and suspended solids, to consented levels. For Newthorpe, an Enhanced Biological Phosphorus Removal (EBPR) process utilising a modified University of Cape Town (UCT) configuration is implemented.

Influent first enters an anaerobic zone, creating favourable conditions for polyphosphate-accumulating organisms (PAOs) in the absence of oxygen and nitrogen. Here, PAOs assimilate volatile fatty acids, enhancing their competitive viability during subsequent aerobic treatment.

Next, the process advances to an anoxic zone, where recirculated activated sludge (RAS) from secondary settlement is introduced. This recirculation not only distributes bacteria through the system but also conveys nitrogen oxides produced by ammonia oxidation in the aerobic phase. In the anoxic environment, these nitrogen oxides are converted to nitrogen gas, which is then released to the atmosphere.

The third stage involves the aerobic zone, wherein air is supplied to promote three key processes:

- Nitrification, transforming ammonia into nitrogen oxides, which are subsequently denitrified to nitrogen gas in the anoxic zone.

- Bacterial energy production derived from organic constituents within the sewage.

- Uptake of volatile fatty acids by PAOs, resulting in phosphorus accumulation greater than that released during the anaerobic phase, thus achieving enhanced biological phosphorus removal.

Final sedimentation

Newthorpe STW final settlement tanks – Courtesy of MMB

Final sedimentation occurs in the final settlement tanks (designed and built by Tank Consult Ltd) , where phosphorus-enriched sludge is removed. This sludge is either recirculated to the anoxic zone or processed further, including thickening and digestion for gas and cake production.

Tertiary treatment

The tertiary stage further decreases effluent phosphorus concentrations, specifically targeting non-organic forms. Ferric sulphate is dosed upstream of the tertiary solids removal unit to coagulate particles into larger flocs, which are subsequently eliminated via physical filtration.

Newthorpe employs the FilterClear (mixed media filtration) system, developed by Bluewater Bio Ltd, which, upon commissioning, represents the largest installation of its kind in wastewater treatment.

FilterClear mixed media filtration system – Courtesy of MMB

Newthorpe STW: Supply chain – key participants

- Client: Severn Trent

- Principal designer & contractor: Mott MacDonald Bentley

- CFD analysis, planning, mining studies: Mott MacDonald

- CFA piling: Van Elle

- ASP FRC: Bell Formwork Services Ltd

- Inlet works FRC: TCL Structures UK Ltd

- Design/build FRC final settlement tanks: Tank Consult Ltd

- Rising main HDD: Joseph Gallagher Ltd (Johnston Trenchless Solutions)

- Mechanical installation: Alpha Plus Ltd

- Electrical installation: Main Electrical

- Tertiary solids removal: Bluewater Bio Ltd

- Gravity belt thickeners: Alfa Laval

- Inlet screens: Longwood Engineering Company Ltd

- Grit removal plant: Tuke & Bell Ltd

- Scraper bridges: EPS Water

- Glass-coated steel tanks: Goodwin Tanks

- MCCs: CEMA Ltd

- Kiosks: Morgan Marine

- Steel buildings: LGSF

- Aeration diffusers for ASP: Xylem Water Solutions

- Polymer dosing: Richard Alan Engineering

- Alkalinity dosing: Lintott Control Systems

- Ferric dosing: Colloide

- Composite steel-reinforced pipes: Aquaspira Ltd

- DI pipework: Saint Gobain PAM UK

- Mixers, blowers & submersible pumps: Sulzer Pumps Wastewater Ltd

- Progressive cavity pumps: NOV

- Booster pumps: Grundfos

- Valves: AVK UK Ltd

- Penstocks: Waterfront Fluid Controls Ltd

- Lifting equipment: T Allen Engineering Services Ltd

- Steelwork & storm distribution chamber: GT Fabrications

- Steelwork: GWH Fabrications Ltd

- Steelwork & GRP platforms: APT Marine Engineering Ltd

- FE monitoring: Servitech International

- Fencing: Town & Country Fencing (Midlands) Ltd

- Road surfacing: Interclass

Heanor storm and sewage transfer pumping station – Courtesy of MMB

Site progress: Heanor

At Heanor, the new transfer and storm pumping station is now fully operational, marking the successful completion of the project. The construction overcame significant challenges, particularly the close proximity of surrounding structures and persistent groundwater issues. To address these, a wall of secant piles, installed by Van Elle, was integrated into the permanent works, providing a crucial groundwater cut-off and ensuring the safe installation of the pumping station.

The blind tank, a 1,700m3 glass-coated steel unit from Goodwin Tanks, is now completed and in service. This tank is fed from the steel storm distribution chamber, fabricated by GT Fabrications.

Once the blind tank is full, the same distribution chamber spills into the two former primary settlement tanks (PSTs), which have been successfully re-purposed as storm tanks. This innovative approach provides increased stormwater storage capacity, contributing to a reduction in spills to the river. There remains further opportunity in the future to adapt additional structures on site, offering continued improvements in environmental performance and further minimising river spills.

The motor control centre (MCC) was powered up in September 2024, and the entire site was brought into its final operational configuration by December 2024; seamlessly meeting regulatory requirements. The facility is now actively supporting the broader network, reliably transferring flows to Newthorpe STW and managing stormwater events as designed.

Heanor storm blind tank (left) and storm distribution chamber – Courtesy of MMB

Site progress: The rising main

The 2.5km 450mm dual rising main connecting Heanor STW to Newthorpe STW, with a 250m section crossing the River Erewash and Canal Erewash using HDD by Joseph Gallagher Ltd, is now fully completed, tested, and operational. It is successfully transferring flows as part of the live network, supporting the EBPR process and meeting all regulatory commitments.

The route of the rising main crossed several historical mine sites. MMB’s geotechnical team conducted an investigation to understand the status and position of the mine entries and any other mine-related features along the route. Additionally, a watching brief was in place to quickly identify any non-natural ground features. Thanks to this effort all the risks were mitigated, and the rising main was safely constructed.

Site progress: Newthorpe STW

At Newthorpe STW, the principal phases of construction have been successfully concluded. The outstanding operations now comprise ancillary works including landscaping, seeding to provide Biodiversity Net Gain project objectives. At the time of writing (August 2025) the site roads have been completed.

The motor control centre (MCC) was successfully energised in 2024. Initial commissioning focused on validating the new treatment processes, including comprehensive checks on all mechanical equipment and monitoring instruments, followed by testing of the ASP aeration system.

During the process stabilisation period, flows were directed back to the existing facility via the new TSR pumping station and a temporary pipeline. This ensured that all discharge consistently met regulatory and environmental requirements while the biological systems developed. Continuous online monitoring and regular sampling confirmed the facility’s compliance throughout this phase.

Once the ASP achieved process maturation, flows were switched to the new outfall arrangement. This handover was carefully managed to maintain both water quality and process stability. From the first day, the plant operated successfully and met all water quality standards.

ASP during its final phases of commissioning in December 2024 – Courtesy of Mott MacDonald Bentley

Driven by collaboration

The project’s success is a direct result of robust collaboration among all stakeholders. The design teams operated under an integrated “one team” model, leveraging global expertise to deliver innovative solutions. This approach ensured effective coordination and maximised the impact of technical knowledge from diverse backgrounds.

The supply chain, comprising over 65 suppliers and subcontractors, played an essential role in the project’s completion. Their contributions were instrumental to maintaining schedule and quality, demonstrating the critical importance of comprehensive supply chain engagement in advancing the water industry.

A strong partnership between MMB and Severn Trent was central to achieving project objectives. The active involvement of Severn Trent’s operational team provided invaluable practical insights that informed commissioning and handover, enhancing operational reliability.

MMB supported industry growth by integrating 11 apprentices and placement students across all disciplines. The project prioritised links with academic institutions, hosting several site visits and serving as a Loughborough University case study for final-year civil engineering students.

(left) Sludge thickened tank and sludge thickening building and (right) anaerobic and anoxic tank- Courtesy of MMB

Commissioning for the future

MMB and Severn Trent worked together during commissioning to optimise greenhouse gas emissions at the Newthorpe STW. Instrumentation was installed on site to measures nitric oxide (NO) and nitrous oxide (N2O) on the ASP, providing critical data for ongoing improvements.

Nitrous oxide was continuously monitored during the biological removal of ammonia in the nitrifying ASPs. The data collected during and after commissioning at Newthorpe provides Severn Trent with a robust baseline process emissions factor and valuable understanding of the mechanisms that produce nitrous oxide.

While large volumes of operational data are normally generated by the plant, the Comm Plus initiative now processes this information, turning it into meaningful, near real-time performance insights displayed on an accessible dashboard.

The integration of ammonia load and process emissions monitoring exceeds standard requirements and gives the Operations team a powerful tool to balance the plant’s overall environmental impact – comparing discharge water quality with atmospheric emissions – to drive ongoing optimisation and sustainability.

Blowers kiosk and ASP at Newthorpe STW – Courtesy of MMB

Conclusion

Newthorpe STW and Heanor Milnhay STW have been successfully merged as part of one of the major AMP7 Severn Trent projects, with Mott MacDonald Bentley serving as principal designer and contractor.

The completed expansion at Newthorpe STW now stands as one of the largest enhanced biological phosphorus removal sites in the region, serving a population equivalent of 100,000. Newthorpe STW has consistently achieved the stringent permit of 0.2 mg/l while minimising chemical use for phosphorus removal.

The scheme was delivered on schedule, with the biological maturation of the EBPR process achieved ahead of the regulatory deadline in December 2024, ensuring enhanced environmental compliance and operational excellence for the years ahead.

Newthorpe chemical dosing and MCC - Courtesy of MMB