Donegan Civil Engineering

Wilmslow WwTW – Civil Engineering Works

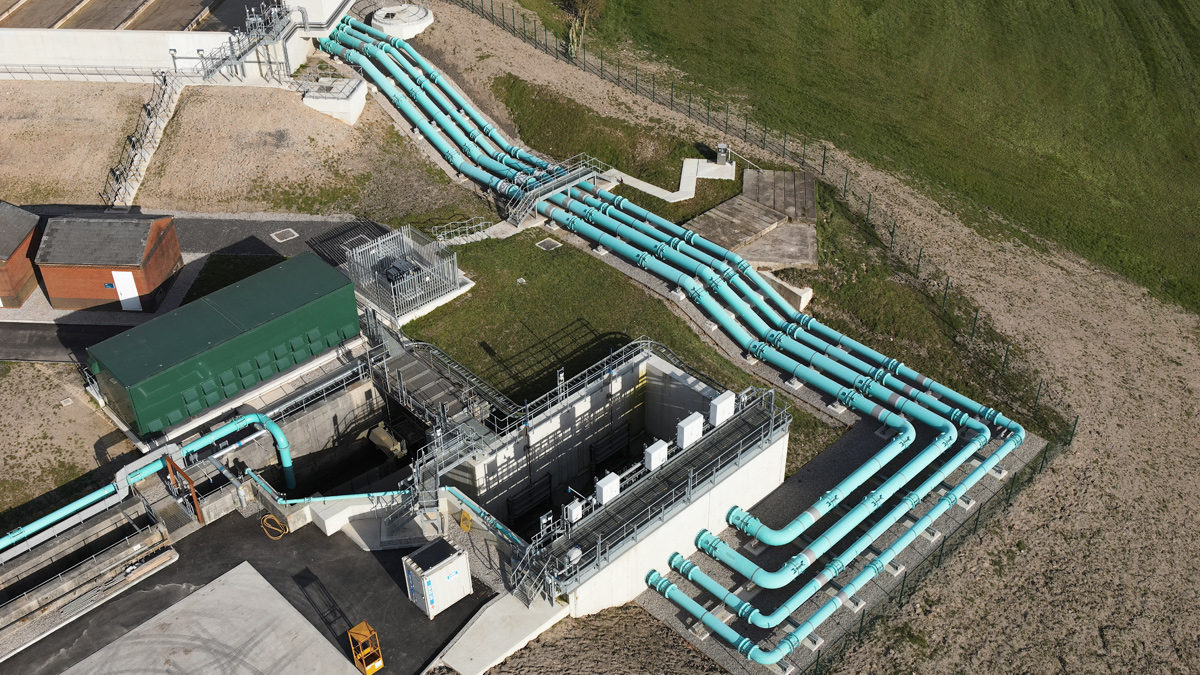

Reinforced concrete bases & chambers, containment & access upgrades, and ducting & drainage to create a clean, MEICA-ready interface

Wilmslow WwTW – Civil Engineering Works

WES engaged V J Donegan & Co. Ltd to deliver the civil engineering infrastructure for a new process installation at Wilmslow WwTW. Working safely in a live process environment, we constructed reinforced concrete bases and chambers, delivered containment and access upgrades, and installed ducting and drainage to create a clean, MEICA-ready interface.

United Utilities’ solution for Wilmslow comprises new process equipment facilities, EDM on storm spills, FFT monitoring and a new potable-water system to support the site.

Scope of Works

V J Donegan’s solution encompassed:

- Reinforced concrete foundations & slabs for equipment kiosks – Precision-set RC slabs and upstands built to tight tolerances for “plug-and-play” installation of new process equipment.

- New valve chamber & interconnecting civils – Construction of the two-way valve chamber with associated excavation, surrounds and backfill, plus the interconnections specified for the process system.

- Containment & bunded delivery area – Construction of a kerbed, membrane-lined, falls-managed delivery area with speed humps and drainage in order to improve safety and compliance for tanker operations.

- Service trenching, ducting & draw pits – Trenching for process lines, multi-way duct routes and draw pits to suit WES’s kiosk layouts and future maintenance access.

- Access, reinstatement & handover – Traffic-management features, neat tie-ins, and reinstatement to leave a MEICA-ready platform aligned to United Utilities’ monitoring and process requirements.

Challenges & how we solved them

- Live-site working, tight footprint – We sequenced slabs, chambers and services to open safe parallel work-fronts and maintain clear vehicle/pedestrian routes for the WwTW which was still live during construction.

- Interfaces & tolerances – Early set-out checks with WES ensured bolt patterns, penetrations and duct positions landed first time, reducing on-site assembly and outage windows.

- Deliveries & containment – The bunded off-loading area with kerb restraint, drainage and traffic calming was designed to streamline deliveries and protect the environment.

Outcome / Client benefits

- A clean, compliant civils platform enabling EDM and FFT monitoring equipment to be installed and commissioned efficiently.

- Safer, quicker deliveries via a purpose-built, bunded delivery area and improved site access.

- Low-disruption build aligned with off-line installation principles to minimise interaction with the live plant.

For More Information, contact us at http://www.donegan.co.uk

Westminster Road, Macclesfield

Construction of an access chamber onto an existing brick culvert to provide an outfall for surface water

Ground Engineering

Sewers

Stormwater Storage

Weaverham WwTW

Green Asset Lab Enabling Works

Concrete Works

Chester Northgate Tunnelling – Chester City Centre

Client: Vinci PLC / Cheshire West & Chester City Council Value: £2,700,000 Project Description/Main Operations V J Donegan & Co Ltd were approached to work alongside Vinci PLC and Cheshire West & Chester City Council to provide a constructable solution for a new surface water outfall, from the Northgate Development Phase 1 in the heart […]

Ground Engineering

Sewers

Stormwater Storage

Tanks

The Airfields, Deeside

Large-diameter caisson and dewatering for regeneration infrastructure at the former RAF Sealand.

Ground Engineering

Precast Concrete

Stormwater Storage

Temporary Works & Shoring

Medlock CSO Screening

Client: Costain / United Utilities Value: £2,200,000 Project Description/Main Operations V J Donegan and Co Ltd was enlisted to collaborate with Costain in via their MSP Framework in partnership with United Utilities on the Medlock CSO Screening project. This initiative aimed to minimize the environmental impact of combined sewer overflows into the Medlock watercourse, an […]

Ground Engineering

Piling

Sewers

Stormwater Storage

Stormwater Storage

Tanks

Liverpool Waters, Stanley Dock – Civil Engineering Projects, Liverpool

Client: Excalon / Vital Energi Value: £600,000 Project Description/Main Operations V J Donegan & Co Ltd were approached by Excalon to provide a solution for laying 2 no. 710mm dia. gas pipes across Great Howard Street. Due to the high concentration of utility services within Great Howard Street it was deemed that an open-cut technique […]

Ground Engineering

Piling

Precast Concrete

Sewers

Tanks

Fujiclean Tank Installation – South Cheshire

Pioneering the FujiClean wastewater treatment system at Calverhall in collaboration with Costain and United Utilities.

Ground Engineering

Tanks

Temporary Works & Shoring