Minworth STW – ICA Enablers Scheme (2018)

Minworth STW - Primary settlement tank area - Courtesy of NMCNomenca (now Galliford Try)

Minworth is Severn Trent Water’s (STW) largest sewage treatment works serving an population equivalent (PE) of 1.75 million from Birmingham, with a full flow to treatment of 1,070Ml/d. The plant treats sludge from a PE of 2.3 million, which is made up of indigenous sludge plus imported sludge. As part of Severn Trent’s Capital Investment Scheme, the new Minworth Thermal Hydrolysis Plant (THP) is being installed on the site which is designed to treat up to 250 tonnes of dry solids per day and will deliver an enhanced sludge cake and increased biogas yield. In order that the THP system may integrate into the site network, it was identified that investment was required to upgrade the SCADA system, replace legacy PLCs and improve the network performance and resilience around the sludge area. However, STW had more of a long-term view and applied the same investment logic to the remaining process areas on site such that the whole site was brought up to an acceptable ICA standard. Additional instrumentation was required across the primary and SAS sludge route to gather operational performance data to enable the THP plant to be controlled effectively. The £3.5m contract was awarded to NMCNomenca (now Galliford Try).

Sludge route instrumentation

The primary treatment process at Minworth consists of 22 (No.) circular primary settlement tanks (PSTs) each with its own dedicated desludge ram pump. Each bank of PSTs has its own common primary sludge well, from which sludge is transferred over to the thickening building. There was no instrumentation on the primary sludge other than flow meters on the common delivery lines to the thickeners, so there was no way of knowing how each PST was performing.

On each PST desludge line, a Siemens electromagnetic flow meter was installed to measure the delivery flow from each PST. Downstream of the flow meter a Hach Lange Solitax sludge density probe was installed to measure the dry solids content of the delivered sludge. This could therefore determine the tonnes dry solids (TDS) content of the sludge being delivered from each PST, which would go into the overall sludge calculations for the day but would also be used as an indicator to operations of how the PST was performing.

Installation of the instruments posed a significant challenge as the pipework between the ram pumps and the reception chambers was below the concrete hardstanding.

The original brief was to construct a chamber for each flow meter and each dry solids monitor, however, after detailed site surveys and trial holes it was determined that a single chamber could be constructed which would house the flow meters and density instruments for 2 (No.) ram pumps, thus reducing the civils construction by 75% and allowing the use of the multi-channel sludge density monitors whereby two density probes could be connected to one controller.

Instrument chamber – Courtesy of NMCNomenca

Additional to the volumetric and quality instruments, a Pulsar sludge finder level detection probe was installed on each primary settlement tanks to measure the height of the sludge blanket within each PST.

New control software was designed and implemented with Severn Trent Water to improve the overall desludging regime of the tanks, whereby as PSTs typically desludge on a regular timed basis, the software changes implemented an algorithm to aim to maintain the sludge blanket to a set-point level and changing the desludge time dependent upon change of the sludge blanket level. This method improves the stability of the dry solids content, thus maintaining a more consistent dry solids feed to the new THP plant.

Other improvements made included monitoring the sludge density when desludge was in operation, and if the density dropped below a low-level set-point the desludge operation would be aborted to avoid thin sludge being carried forward. Additionally, if a PST had a high sludge blanket level, its desludge operation would be prioritised over other PSTs with a lower sludge blanket.

A density probe was installed within the SAS thickening delivery main upstream of the existing flow meter to measure the TDS content of the thickened SAS to allow the volume and TDS content of the SAS to be included within the overall sludge calculations. This allowed the ratio of Primary to SAS sludge to be monitored.

Minworth is a central hub for tankered imports of SAS and primary sludge, and as these sludges were delivered into the existing tanks the measurement of quantity and quality of the sludge posed a problem. At each sludge import location there were existing JRP data loggers which already measure the volume and quality of the sludge, but with the data going directly off site to an external company it could not be exported into the STW domain.

Working with STW and JRP, an ethernet connection was made to each logger, and the operating system software of the logger modified by JRP such that it would send a CSV file containing the data for each delivery directly to the new SCADA system. This would then be automatically accessed by the SCADA servers and the data populated directly into the Historian system.

Instrument chamber showing flow meter – Courtesy of NMCNomenca

Scada system

The existing SCADA system was made up of three separate systems; a WinCC system serving the power generation area, and a Servelec ScopeX and Rockwell FTView SE system serving the process treatment site. The Servelec system was installed circa 1998 and monitored the whole site. When the primary and secondary treatment systems were upgraded in 2009 the FTView SE system was installed to primarily monitor the upgraded plant.

Modifications were made to both systems in the subsequent years, but it became problematic for operations having to work on two separate systems.

As part of the ICA Enablers Scheme, a single SCADA system was to be installed to monitor the entire site. Historically, the Information Technology (IT) of Severn Trent has been disparate from the Operational Technology (OT) system, meaning that the two could never properly co-exist. For this scheme Severn Trent Group Technology was engaged at an early stage in the systems design such that it would integrate into the corporate IT system and could be maintained, upgraded and patched in line with other IT assets.

SCADA platform consisted of a number of separate virtual servers running the application software running on two HP physical servers running VMWare EXSi. The use of virtualisation for a SCADA application was a first within Severn Trent and gave benefit to the fact that backup and disaster recovery was simpler as well as reducing the overall cost by reduction in physical hardware.

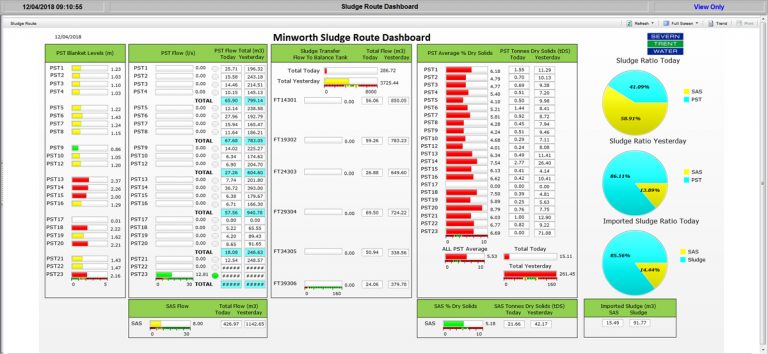

Sludge route dashboard – Courtesy of NMCNomenca

The SCADA software chosen for the project was Rockwell FactoryTalk View SE for the graphical interface with Historian SE for datalogging and reporting, and VantagePoint for the process dashboard displays.

For a large site, Minworth did not have a comprehensive overview of site performance, whereby operators could tell at a glance what the status of the process was. Even for a site the size of Minworth, the entire process could not realistically be shown on one screen, so dashboards were created per process area. The initial dashboard was created for the sludge treatment scheme, such that operators had time to familiarise themselves with it months before the THP came on line. Further dashboards were created for the ASP process and the power generation/gas export process. These dashboards were designed in conjunction with Severn Trent Operations, to ensure the most relevant information was displayed.

MinworthSTW – ICA Enablers Scheme: Table of designers, contractors and suppliers

- Principal designer & Principal contractor: NMCNomenca

- Civil sub-contractor: JMC Civils

- ICA sub-contractor: CEMA Ltd

- Flow meters: Siemens

- Level instruments: Pulsar

- Quality instruments: Hach-Lange

- PLC hardware & SCADA software: Rockwell Automation

Communications network

The existing communication network consisted of an original fibre optic network which was installed circa 1988 which served the process areas monitored by the Servelec SCADA. This network was extended for the process improvements in 2009 which served the FTView system. Furthermore, there were a number of separate DH+ networks from which Logix Gateways were employed to provide a communications path to SCADA.

For the ICA Enablers Scheme, the scope was to remove all legacy networks which served PLCs which were monitored on the SCADA and upgrade the entire SCADA layer to Ethernet only. To facilitate this, three new resilient ring networks were installed in the ASP, digestion, and generator areas. The new networks were designed to use the same grade of fibre optic cable and managed network switches as per the rest of the site. The three new networks were coupled to the main network ring by use of the Hirschmann ring coupling feature, with a redundant ring coupling made to the main network by use of spare fibre cores from the existing ring. This ensured both resilience and maintainability of the network.

MCC1 PLC5 replacement with ControlLogix – Courtesy of NMCNomenca

PLC replacement

The scope for the project identified a number of obsolete/unsupportable PLCs to be replaced and a large number of PLCs to be upgraded. These ranged from large Allen-Bradley PLC5 controllers through to small Toshiba fixed controllers. The main digestion feed MCC contained an Allen-Bradley PLC5 which communicated to SCADA on DH+ and to remote racks on RIO. This process could not be shut down for an extended period due to the importance of maintaining digester feed. The use of Rockwell’s PLC5 migration kits was employed to reduce the overall downtime and minimise wiring errors such that the entire PLC5 racks were replaced with ControlLogix and powered up within 3 hours and the process was fully operational in auto 4 hours later.

For the majority of the existing estate of SLC500 controllers, the ideal scenario would have been to upgrade the entire chassis to either ControlLogix or CompactLogix but there simply was not the budget available to do this nor the amount of down time/process interruptions available. The CPUs were upgraded to Ethernet by exchanging the existing CPU to an SLC5/05 to allow Ethernet connectivity to the new SCADA system and any existing Panelview 550 HMIs were replaced with new Panelview Plus terminals and new process mimics drawn to match the SCADA mimics.

The overall scheme was completed four months ahead of the original programmed completion date largely due to the collaborative working processes between NMCNomenca, Severn Trent Water and the sub-contractors.