Rathlin Island Borehole Project – Ion Exchange Plant (2020)

Rathlin Harbour, Church Bay and the Eastern side of the island - Courtesy of FM Environmental

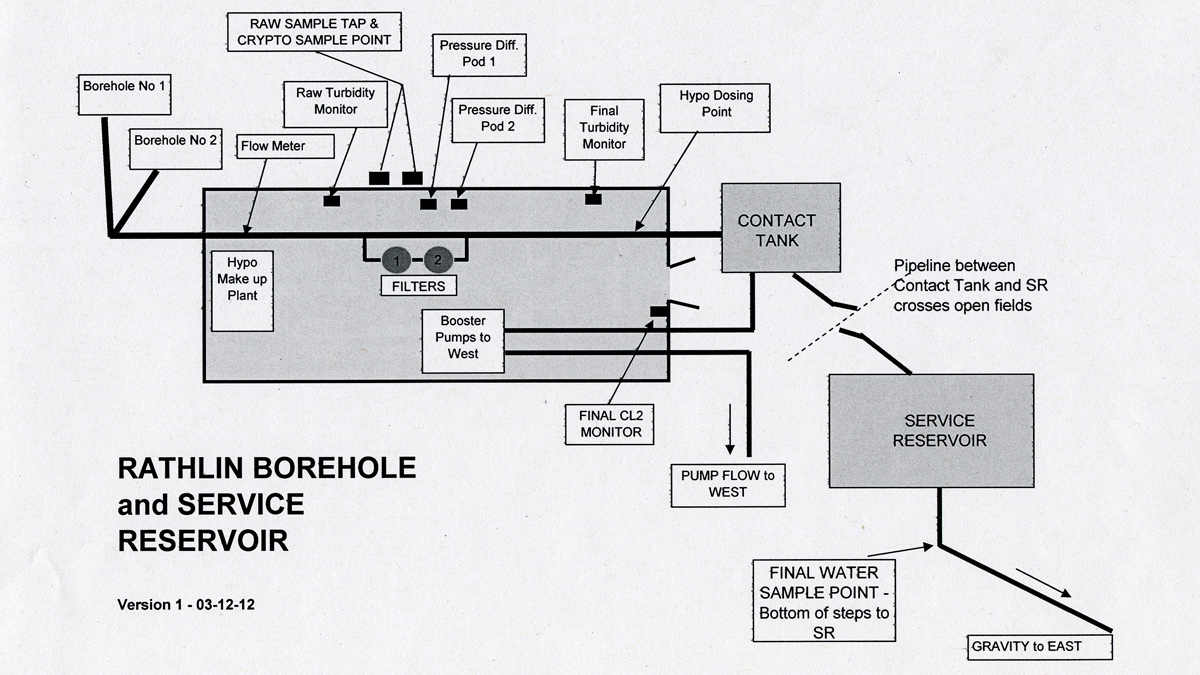

In summer 2019, Northern Ireland Water commenced upgrade works to the water supply on Rathlin Island, Northern Ireland’s only inhabited offshore island. The current public water supply on Rathlin Island is supplied from groundwater. It consists of a pair of closely located boreholes feeding a simple double cartridge type filtration system with sodium hypochlorite dosing for disinfection. The chlorinated water is fed to a contact tank. The supply is then fed to the service reservoir which supplies the main habitation of Church Bay and the east of the island. A booster station was relocated from the borehole compound to the outlet of the service reservoir in 2015, and this feeds the west of the island.

Background

Rathlin Island is just six miles across the Sea of Moyle from Ballycastle and is home to a slowly increasing population of approximately 150 people. The island is 6 miles long by 1 mile wide and is a popular tourist attraction, especially over the summer months, with many visitors to attractions such as the RSPB Seabird Centre, the lighthouses and numerous walking routes.

On 2 March 2018, the Drinking Water Inspectorate (DWI) issued a Notification of Consideration of Provisional Enforcement Order (CPEO) to NI Water (NIW) for Contravention of the Regulatory Standard for Trihalomethanes: Total. The final water consistently had a total trihalomethanes (THM) concentration of greater than 50 µg/L and had, on occasion, exceeded the 100 µg/L statutory limit and the World Health Organisation (WHO) index for THMs in drinking water due to ‘the high level of brominated forms of THMs’. The CPEO stated that a review of the treatment process was required, and remedial measure should be taken.

Existing water treatment kiosks – Courtesy of Doran Consulting

Appraisal stage

Doran Consulting was appointed by Northern Ireland Water to review the condition of the existing disinfection system and the treatment provided at Rathlin Island Water Treatment Works (WTW) with regards to the issue concerning THMs. The aim of this was to identify potentially viable treatment solutions to reduce the risk of THM contraventions in the future, and to recommend remedial works that would improve the general operation of the works.

The greatest challenges for this application were that the volumes of potable water supplied are small and the site is remote. Any treatment process must be robust and require only minimal maintenance. All new works proposed were to be automated as far as practicable, and process robustness prioritised.

Three main treatment process categories were examined for their viability as a means to prevent the formation of THMs: membrane filtration, electrochemical processes and adsorption processes. The possibility of removing THMs after their formation was also considered, but after investigation, it was ultimately not considered viable.

Raised cover over borehole – Courtesy of Doran Consulting

The chemistry of the water is a little unusual. The creation of THMs is common in water containing certain forms of dissolved organic carbon (DOC). DOC is low in the Rathlin Island raw water, but the relatively high bromide content of the raw water promotes the creation of brominated THMs. Hence reduction of both bromide and DOC was targeted. Only membrane and adsorption treatments were identified as viable options. However, it was not possible to design an adsorption treatment system based on available information, so a comprehensive series of bench-scale trials, including measurement of THM formation potential, were carried out on a range of adsorbents. This showed that ion exchange was the most suitable means to reduce THM formation potential through the reduction of DOC and bromide and would allow regulatory compliance with THMs to be met.

Treatability trials were carried out to examine several ion exchange resins to find the resin which would achieve the best performance. A regeneration system was also required to regenerate the resin once it has reached the end of its treatment run. It was proposed that waste brine used in this process would be disposed of on the island’s wastewater treatment works (WwTW).

The review also examined alternative disinfectants to reduce THM formation in the distribution system. A number of possible alternative disinfection technologies were investigated which would provide disinfection without forming THMs. However, there are significant drawbacks associated with these: some cause the formation of other disinfection by-products, which are also regulated, and others do not provide any residual, therefore the water would still need to be chlorinated. In addition, many disinfection techniques have significant health and safety concerns associated with them which would especially cause issues on the Rathlin Island site.

Therefore, based on the assessment of the information it was considered that the existing strategy of disinfection using hypochlorite was the most suitable method. The existing system had, however, reached the end of its useful life and it was proposed that it be replaced.

Existing borehole and service reservoir schematic (2012) – Courtesy of NI Water

Early contractor involvement work

Doran Consulting managed the Early Contractor Involvement (ECI) stage of the project, prepared the ECI specification and contract, and project managed and supervised the enabling works. The enabling works involved gathering site information to help define the scope of the works and, in conjunction with the ECI contractor, Euro Environmental Services JV, further refine that scope.

Project management

The NEC3 Engineering and Construction Contract, Option A: Priced Contract with Activity Schedule was chosen for the main construction contract and Euro Environmental Services JV was appointed by NIW as design and build contractor in March 2019.

Doran Consulting developed the scope of works and contract documentation and provided project management, site supervision and health and safety advisory services throughout construction.

Supply chain

- Client: Northern Ireland Water

- Client professional services: Doran Consulting

- Main contractor: Euro Environmental Services JV

- Civil contractor: Euro Services Contracts Ltd

- M&E contractor: FM Environmental

- Structural designer: Equilibrant Ltd Consulting Engineers

- Propriety process supplier: IXOM

- Sodium hypochlorite dosing skid: Grundfos

Steel structure during construction – Courtesy of Doran Consulting

Works

A structural steel-clad building was constructed to house the new equipment. A new ion exchange treatment unit (3.0 l/s Mico Mini Treatment System) was installed to reduce bromide and DOC. The new ion exchange unit is a MIEX Mini system produced by IXOM. This is a fluidised bed ion exchange system. The system has sufficient resin capacity to treat the maximum flow of 120m3/d at a regeneration rate of 1000 bed volumes.

Water is diverted from the existing treatment line by a valved tee arrangement and forwarded to the new treatment, before returning to the existing treatment stream. This diversion occurs downstream of the existing 1µm cryptosporidium filters to prevent fouling of the ion exchange media.

A regeneration system was installed to regenerate the resin once it reaches the end of its treatment run. The system consists of a brine tank to hold the made-up brine solution, backwash pumps to pass the brine through the resin, and a waste brine pumping station to store the used brine. A salt batching system was also installed to allow automatic feed of salt.

(top left) Sodium hypochlorite dosing skid – Courtesy of Doran Consulting, (bottom left) process water pumps and 20 µm automatic strainer which captures resin carryover in the waste brine and (right) New MIEX ion exchange treatment – Courtesy of FM Environmental

The waste brine pumping station was installed to carry waste brine to the existing NIW sewer network. Approximately 900m of new sewer was constructed from the treatment works site to the discharge point on the NIW sewer line. Currently, in agreement with NIW Wastewater, the waste brine from each regeneration (3300 litres) can be accepted over a period of 12 hours (5am to 5pm) over a total of 9 days. In the long term, it is anticipated that this waste brine can discharge to the sea, and an application process for a marine discharge licence is ongoing.

A new free-standing enclosed Grundfos sodium hypochlorite dosing skid was installed in the chlorine dosing kiosk to replace the existing hypochlorite dosing system that had reached the end of its usable life. The new system consists of duty standby DDA profibus Grundfos pumps which dose neat sodium hypochlorite directly from 25L drums into the pipework manifold. The new dosing system is accessible via the MCC HMI in the new control building to provide visibility for NIW operators of the whole treatment from the new building.

Two additional 1 µm cryptosporidium filters were installed in parallel to the existing two filters. The pipework and valving arrangement allows either pair of filters to be utilised when required.

The existing borehole pumps were replaced with variable speed drive pumps. This now allows the borehole pumps flow rate to be altered depending on well levels as opposed to the previous start/stop operation.

Two new additional 1 µm cryptosporidium filters – Courtesy of FM Environmental

Challenges

The most critical element of the construction project was meeting the 30 November 2019 deadline set by the DWI. This was made particularly difficult given the remote location of the works. Rathlin Island is only accessible via either a pedestrian-only ferry or by a vehicle ferry. These operate regularly throughout the day during the summer months and less frequently during the winter months. Frequent stormy weather and high waves over the winter months of 2019 caused numerous cancellations of ferries, which limited access for construction staff and for delivery of construction materials and equipment.

Given that the ferries cater for other industries on the island, tourists and for the local people, bookings were not always immediately available. Much of the programming took this into consideration, and careful planning by the contractor ensured large items, such as the structural steel and the MIEX process tank, were booked well in advance.

As well as the isolated location of the treatment works on an island, the confined nature of the site itself also was challenging. During construction, the treatment works remained fully operational, and therefore access had to be maintained at all times to allow NIW operators to carry out routine maintenance. This was crucial as this is the sole water supply on the island.

Control panel and HMI installed in new treatment building – Courtesy of FM Environmental

Construction work also had to take into consideration the road network and tourism on the island. The ‘Puffin Bus’, which transports tourists to the RSPB Seabird Centre, runs throughout the day along the same road that provides access to the WTW site. There is no alternative road to access this western section of the island.

This meant that the construction of the 900m long waste brine pumping main could not take place within the open season of the RSPB Seabird Centre (April to end of September), and the contractor had to ensure that access for islanders was not disrupted during the construction. Therefore, the Contractor mobilised a specialist drilling rig to allow the pumping main to be installed via directional drilling to limit disruption and also speed up construction time.

There are also no modern concrete mixing plants readily accessible on the island, and all concrete used in the construction of the new building and associated works were mixed by local tradesmen using the more traditional methods of tractor and a cement mixer.

During the later stages of the commissioning of the ion exchange system, the contractor installed a ‘remote dial in system’ to assist NIW operators in the monitoring of the new plant when staff were off site. This system also allows faults to be reset and will also notify both NIW and the Contractor should any modifications be required on site. This system remains in place and will continue to assist in the handover process to NIW over a period of time.

Rathlin Island Borehole WTW – Courtesy of FM Environmental

Conclusion

At the time of writing (June 2020), the new MIEX ion exchange plant is operational and continues to produce water for beneficial use. Final commissioning and testing was delayed due to storms in early 2020, giving access difficulties in travelling to Rathlin Island and also due to Covid-19 restrictions on the island.

Early contractor involvement from the outset, and choice of the design and build procurement route, ensured the supply chain’s experience and capabilities were drawn on and brought to the fore. This approach was fundamental in ensuring successful delivery in terms of meeting the requirements of the Regulation 31(4) (b) Notice before the deadline of 30 November 2019. The end result is a fit for purpose system in terms of NIW operational needs, which will serve the people and tourist population of Rathlin Island for years to come.