Kineton STW (2021)

MWH Treatment

The Kineton STW required investment in AMP7 due to the introduction of a 0.5mg/l total phosphorus effluent limit, which comes into force by the end of December 2021. The new works is designed to cater for flows from Kineton, Butlers Marston and Radway equating to a combined design horizon population equivalent of 3,946. The existing works comprises an inlet pumping station, a 6mm 2D inlet screen, two dortmund primary settlement tanks, followed by a storm overflow, two granite biofilters, two circular humus tanks a nitrifying aerated filter, two storm reed beds and a sludge holding tank.

The new works design was for a three-pocket aerated sludge plant (ASP), a new final settlement tank (FST), sludge thickening, tertiary solids removal (TSR) and associated pumping stations.

Innovative solution selection

The existing works is on a very constrained site and so the solution required low-footprint technologies that could be delivered within Severn Trent’s available budget. The selected process was the inclusion of an innovative thinking solution incorporating a pocket enhanced biological phosphorus removal (EBPR) activated sludge plant (ASP) and final settlement tank (FST) into a combined structure, known as the ‘compact plant’. This innovation requires wrapping a conventional pocket ASP around an FST. This differs from a normal process layout which would involve separate structures and is an evolution of the oxidation ditch variant.

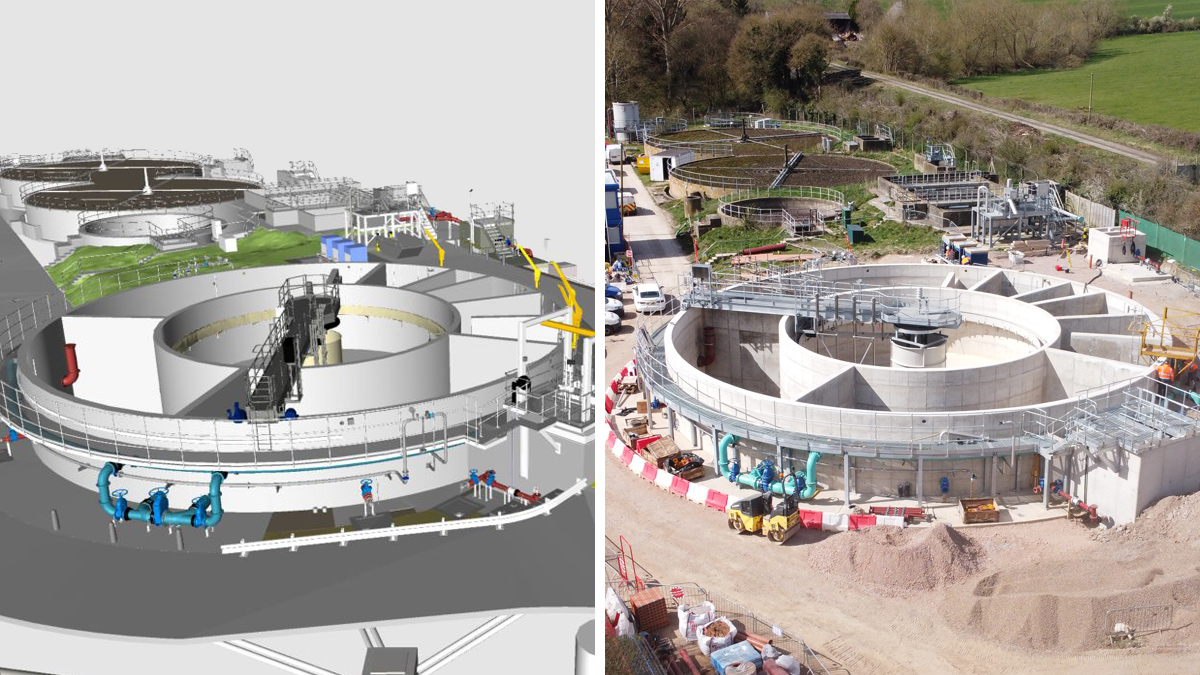

Overhead view of the innovative ‘compact plant’ – Courtesy of MWH Treatment

Project initiation and whole supply chain early engagement

To create a vision of how best to design and build the new compact plant, the positive step to involve all key stakeholders at the earliest point in delivery was taken. Engaging with the supply chain early in the process gave an opportunity to challenge, augment and create an innovative design and delivery strategy incorporating the supply chains input to ease and construction safety of the build e.g. during workshops and collaborative planning sessions, every new asset was evaluated for off-site build potential, access and maintenance challenges with the compact plant design and construction in the already tight working environment.

The MWH Treatment team undertook a collaborative approach aligning the design skill set with the construction team specialism to ensure the plant was both functional and constructible, overcoming access, maintenance and operability challenges and elected to take as much construction off-site and to modularise, wherever possible, thus overcoming conventional construction mind-sets.

Poor ground conditions and a deep excavation presented an early challenge in the tight confines for the area allocated for the construction of the pant. A pre augured, 9-12m independent cantilevered sheet piled cofferdam was selected for this excavation as its design omitted any internal bracing.

Collaboration with the construction team led to the move to raise peripheral pipework penetrations up the structure to enable backfilling and the earth works support system to be removed earlier, reducing H&S risk as well as saving money. A self erecting tower crane was also deployed for the construction of the RC structure.

Compact plant cofferdam – Courtesy of MWH Treatment

Kineton STW: Supply chain – key participants

- Client: Severn Trent

- Main contractor: MWH Treatment Ltd

- Full design: MWH Treatment Ltd

- Hydraulic modelling of compact plant: MMI Thornton Tomasetti

- Compact plant RC design: Monostore

- Mechanical installation: MWH Direct

- Electrical installation: S&R Electrical Contracting

- FST bridge: EPS Water

- Chemical dosing rig: EPS Water

- Safety showers & eyebaths: Aqua Safety Showers International Ltd

- MCC and ICA controls: Total Automation & Power

- General civil works: Naylor Construction

- Compact plant sheet piling: Sheet Piling (UK) Ltd

- Aeration equipment: Suprafilt

- Pumps: Xylem Water Solutions

- Thickener plant: Huber Technology

- Thickener SAS tank: Stortec Engineering Ltd

Digital delivery

The project team optimised digital delivery using developing and innovative digital engineering tools to increase efficiency at initiation, design development, assembly and ultimately client operational stages in the project lifecycle.

MWHT undertook both a full digital survey of the site and utilised drones to take aerial images of the site. These were used as the basis of the 3D model but additionally this digital information and imagery was also actively used in the induction process to develop visual awareness of both the works layout and the impact on access. QR codes and BIM images were also used on site boundary posters to inform the local community of the works proposals.

Information was updated as the project progressed giving visitors contemporary overviews of the works and the ongoing construction activities before stepping out onto site.

During the construction of the works, a digital twin of the as-constructed reinforced concrete structures was created which allowed digital comparison between design and build with the outputs being shared with the supply chain to mitigate mechanical interface issues during assembly.

(left) Compact BIM model and (right) Kineton STW as built – Courtesy of MWH Treatment

Process design

MWHT designers worked closely with the Severn Trent Process Design Engineering (PDE) team to agree the use of the compact plant structure in lieu of a conventional ASP. CFD modelling of the compact plant aeration pockets and anoxic/anaerobic zones was conducted to ensure the plant would function as design.

The plant has also been designed for enhanced biological phosphate removal (EBPR), a biological process which enables the client to minimise the amount of chemical needed to achieve the new phosphorous consent. MWHT have designed flexibility into the new plant to provide three modes of possible EBPR use, again allowing the client to maximise the potential for biological phosphorus removal.

Efficiencies and environment

The ‘compact plant’ design provided a greener solution than the clients original requirement saving 580m³ concrete which equates to 42% reduction in carbon and over £400K of material costs. The smaller footprint also mitigates potential proximity to the adjacent public footpath and allowed safe access to the old works by Severn Trent during construction.

The design of the plant was engineered to mitigate potential floatation issues and the level of the compact plant structure was raised to mitigate dewatering.

To mitigate biodiversity losses from the construction of the new plant a 150m² wildflower grassland will be created and this will enable the final design to meet a zero net biodiversity impact.

Electronic induction

The project has used an electronic GDPR compliant induction system for all workers and visitors. This system of completion online prior to arrival allows the site induction to focus purely on the key site-specific dynamic issues enabling people to start work more promptly. Over 840 people have used this system, typically saving over 1095 hours of site time. The digital induction includes a video of the access routes and access restrictions enabling drivers and delivery persons to clearly understand the access routes and restrictions before setting off for site.

Compact plant under construction (March 2021) – Courtesy of MWH Treatment

Innovation and project improvements

- Digital model of works to BIM level II PAS 1192 : 2.

- ‘Compact plant’ pocket ASP solution.

- Collaborative delivery workshops with the supply chain to derive a working design early in the programme.

- Constructability consideration embedded including rotation and level of new compact plant to provide best access for construction and operation, innovative non braced cantilevered cofferdam for excavation and using a self-erecting tower crane for ‘compact plant’ construction.

- DfMA off site build of FST bridge spilt for delivery and spliced on site – this was erected on tank in one day.

- DfMA approach on chemical dosing, TSR and sludge thickener solutions.

- QR codes to keep the public informed.

- Digital twin for as built structures.

- Combining of works return and TSR pumping stations.

- Delivery of plug and play reuse of a previous design for the sludge thickener solution.

Programme

The site construction period was reduced by the use of digital design, selection of compact plant, DfMA and effective site planning to 12 months construction with a projected Completion Date of June 2021 allowing Severn Trent 6 months of optimisation before the new consent comes into force.