Cropwell Bishop STW (2019)

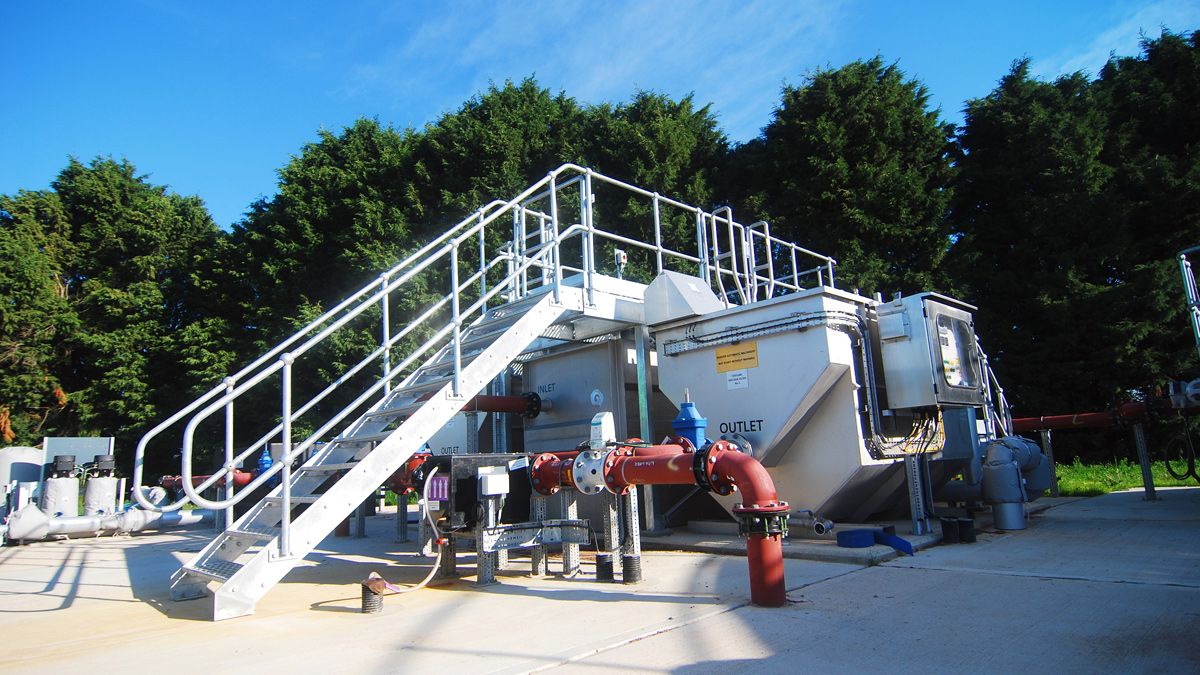

Tertiary solids removal plant - Courtesy of Galliford Try

Located to the south-east of Nottingham, Severn Trent Water’s Cropwell Bishop Sewage Treatment Works (STW) serves 700 residential premises in the village and a number of local businesses, including the Cropwell Bishop creamery, which contributes a significant phosphorous loading to the catchment. It also receives pumped sewage flows from the adjacent village of Cropwell Butler. In total, the works treats waste from a total population of 2800 and a population equivalent of 5775, owing to the commercial loading. The present permit is (BOD) 20, (solids) 40, (ammonia-N) 10 mg/l, and a full flow to treatment (FFT) of 14.1 mg/l. These permits and flow are to remain for the upgraded works.

Existing works

Due to the Water Framework Directive the site will receive a 1mg/l Phosphorus discharge consent and should chemical dosing be required to achieve the phosphorus removal, a corresponding 4mg/l iron discharge permit will be introduced.

The present works consists of screening all flows with inter-stage pumping to a high-level structure containing a flume controlling FFT and storm separation. 2 (No.) Dortmund primary treatment settlement tanks, 4 (No.) granite media biofiltration filters, 3 (No.) Dortmund humus settlement tanks and 1 (No.) storm tank.

Technical solution

Due to the high phosphorus variable loading (up to 30 mg-l P) and circa 55% of total organic load from the Cropwell Bishop Creamery, after a technical risk appraisal the solution chosen was to build a crude ASP with two-stage dosing and tertiary solids removal (TSR) to achieve Bio-P removal. The two-stage dosing (pre-FST and pre-TSR) and tertiary solids removal via cloth media achieve a consistent effluent quality with the variable incoming sewage strength.

The chosen solution of constructing a new ASP process and decommissioning the existing plant will allow the site processes to meet all existing and new discharge permits, removing the hydraulic restrictions for current and future flow and loads up to the new design horizon of 2035.

Design phase

The site was scanned using a Faro3D laser scanner to generate a point cloud of the existing site from which a 3D model was created in 3D Building Information Modelling (BIM) software Autodesk Revit. Other surveys were imported such as topographical and underground surveys to enable pertinent complete information to develop the site arrangement.

The project also used the Collaboration for Revit bolt-on software package. Collaboration for Revit increased efficiency in the design phase by allowing our supply chain partners and Galliford Try to work within a live model simultaneously. As an example, detailing both civil structures and mechanical plant at the same time at different locations all within a live federated model. This had the benefit of reducing the design programme as different disciplines could design simultaneously; clash detection and model interrogation/review could also be done in real time.

The Autodesk Revit model was uploaded to Autodesk360 cloud-based viewing platform for review and comment by the client and other parties. The Revit model was converted to a virtual reality (VR) model and using VR headset and controls was used for design reviews and Hazard and Operability (HazOp) study with the client prior to construction at key stages throughout the project.

Precast concrete crude pocket ASP – Courtesy of Galliford Try

Process plant

A redundant Dortmund tank was re-purposed as a combined inlet and storm balancing pump station. The combined pump station through hydraulic catchment modelling has been shown of sufficient volume to balance peak storm flows and provide at least 2 hours at DWF flow storage volume during emergency.

The FFT pumps lift FFT flows to the crude ASP with storm pumps lifting storm flows up to 45 l/s to a separate existing storm tank. This arrangement ensures peak flows from the catchment can be conveyed without risk of upstream catchment flooding. The re-purposing of this structure removed the need to construct a significant below ground pumping station and reused an existing asset which otherwise would need to be demolished. The existing upstream inlet structure and screen were retained with flows diverted to combined pump station.

A 4 (No.) pocket crude activated sludge plant (ASP) forgoes the requirement for any primary settlement stage as would be the norm for this process with a total volume of 1504m3. The ASP itself is designed in line with STW best practice; 1 anoxic zone (selector) split into quadrants with 1 (No.) submersible mixer in each, and 3 (No.) aerated pockets utilising fine bubble air diffusion and supplied by duty/standby blowers from Aerzen Machines. The aeration system was designed, manufactured and installed by Suprafilt Ltd.

ASP blowers – Courtesy of Galliford Try

A denitrified mixed liquor (DML) recycle pump returns flow at 1.5 DWF (8.31 l/s) from the crude selector zone (Quadrant 4) back to Quadrant 1, thus allowing the bacteria in the mixed liquor, now starved of oxygen or nitrogen to absorb, use and store the phosphorus for energy and hence undertake the biological phosphorus removal from the sewage.

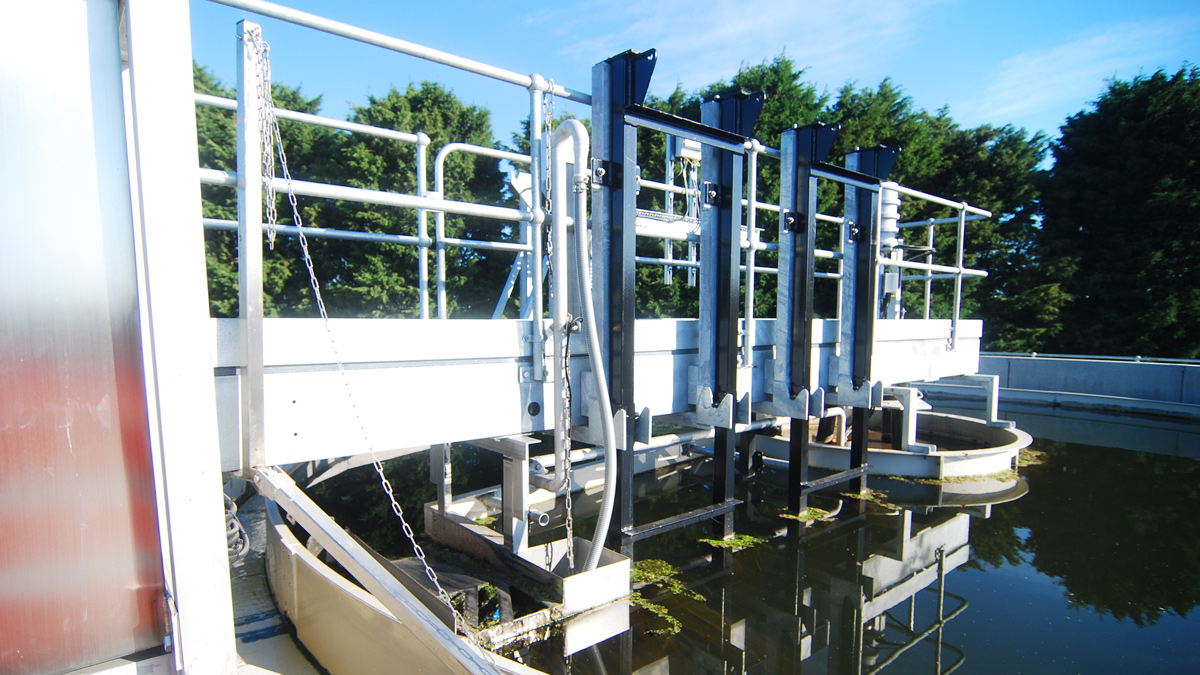

Post-ASP is 1 (No.) 11m diameter final settlement tank (FST). A duty/standby returned activated sludge (RAS) pumping station using Grundfos dry well submersible pumps provides flow back to the ASP to ensure that mixed liquor suspended solids (MLSS) are retained in the ASP at levels around 3000mg/l. Surplus activated sludge (SAS) is taken off via a single Mono progressive cavity pump, thickened and stored ready for tankering off site.The scraper

system inside the FST was designed manufactured and installed by EPS Water using a scraper cassette system, this allows the scraper blade mechanism to be extracted from the tank via crane and maintained at ground level, therefore allowing the process tank to remain in service during this activity.

FST scraper cassette system – Courtesy of Galliford Try

Tertiary solids removal (TSR) equipment comprised 2 (No.) Mecana drum TSR units fitted with course media cloth and supplied with a combined up front flocculation tank; manufactured and supplied by Eliquo Hydrok Ltd. Each unit is sized to 50% of the required flow with each having a separate backwashing facility returning the removed solids to the head of the works via a works return pumping station.

An innovative automatic bypass arrangement was designed and installed to ensure that should one of the units fail the works could continue to process flow without any immediate operational intervention required.

The ASP is designed to undertake biological P removal rather than utilising chemicals to extract the soluble phosphorus from the liquid. However, to provide resilience with varying loads to this process, a 2-stage position, ferric sulphate dosing equipment with a 5m3 storage capacity was installed by Collide Engineering Systems Ltd. The system can dose either pre-FST or pre-TSR or both simultaneously at rates from 0.5 l/h to 8.5 l/h depending on the requirement. The dosing system has numerous control routines utilising fixed dosing rates, diurnal flow patterns and diurnal flow with otho-phosphorus trimming.

Thickening of SAS is undertaken by a single disc thickener manufactured and installed by Huber Ltd. Working with the supplier the project delivered a factory assembled skid mounted solution incorporate the thickener unit and associated transfer pumps, polymer makeup dosing system and the motor control centre, all pre-wired effectively creating a plug and play solution.

Factory assembled and pre-wired sludge thickener plant – Courtesy of Galliford Try

Notable construction techniques

The ASP structure is a prefabricated modular reinforced concrete structure with cast in situ base manufactured and installed by FP McCann Ltd. The structure was placed at a level to avoid unnecessary deep excavation and provide a hydraulic level to avoid further inter stage pumping. Due to tight space constraints on site significant detail and planning for temporary works was considered so that the prefabricated panels could be lifted in to place and supported, using a crane situated in only one position.

The panels were propped until self-supporting with a prescribed delivery and temporary works sequence undertaken to ensure the structure was always structurally sufficient. The brush finished horizontal tie beams across the tops of the walls were extended to double up as walkways and were pre-fitted with guard rails at the factory therefore reducing the amount of working at height risk required to fit these.

Cropwell Bishop STW – Supply Chain

- Main contractors: Galliford Try

- Civil/structural design: Eastwood & Partners

- Ecology/environmental consultants: RammSanderson Ecology

- Precast concrete ASP: FP McCann Ltd

- Round precast concrete tank: A-Consult Ltd

- Fine bubble air diffuser system: Suprafilt Ltd

- MCC: MCS Control Systems Ltd

Cropwell Bishop STW MCC – Courtesy of Galliford Try

- Electrical installation: Main Electrical Ltd

- Mechanical installation: HL Engineering Contractors

- Mecana TSR equipment: Eliquo Hydrok Ltd

- Chemical dosing equipment: Colloide Engineering Systems

- Demolition & earthworks: Total Reclaims Demolition

- Submersible pumps: Grundfos Pumps Ltd

- Mono progressive cavity pumps: NOV Process & Flow Technologies

- Lifting equipment: T Allen Engineering Services

- FST scrapper system: EPS Water

- Trace heating & lagging: Jade Insulation Ltd

- GRP kiosks: Pro-tech GRP Ltd

- ASP blowers: Aerzen Machines

- Sludge thickener: Huber Technology Ltd

The tank was installed and water tight within 9 weeks saving on programme against in situ construction. The delivery of the typically 6.2m x 2.5m wall panels was planned in some detail, with routes to site agreed with the councils and local residents kept informed. The volume of traffic and duration was kept to a minimum using the precast system with deliveries being made outside of peak hours to avoid local disruption.

Ferric dosing installation – Courtesy of Galliford Try

Several options for the construction of the FST including cast in situ reinforced concrete, post-tensioned precast concrete or glass coated steel tanks were evaluated. The chosen solution was the post-tensioned precast option designed, manufactured and installed by A-Consult Ltd, who worked directly with Galliford Try and Eastwoods & Partners Ltd to ensure that the design and installation were able to meet the tight construction period allowed.

To ensure this pre-fabricated steel reinforcement cages for the base were detailed and built off-site to reduce programme. This culminated in the construction of the tank from start to finish on site including base curing of only 3 weeks, of which the walls were erected and self-supporting in a single day. The perimeter walkway was designed to be built in sections away from the structure and bolted in place reducing the time taken to install.

The new process required off line construction since the site had limited available space. Prior to any work starting the abandoned biofilters were demolished and a number of previously buried underground structures were removed. A new pipeline from the existing inlet structure to the combined inlet pump station facilitated by temporary flow management period made the new works ready for commissioning.

Re-purposed humus tank as FFT Storm Pumping Station – Courtesy of Galliford Try

Commissioning

100m3 of SAS from Minworth STW was discharged into the ASP. Seeding was complete within 7 days and the final effluent discharge met the requirement for BOD, solids and ammonia consents. In the interim period where effluent quality was not meeting consent the ASP works flows were recirculated through the biofilter works to enable compliance via a temporary works gravity arrangement agreed with STW process technicians.

The client will now undertake a period of optimisation using the chemical dosing system to bring the final effluent discharge within the parameters of the phosphorus and iron consents.

Throughout the project, key aspects of the project were communicated with the local residents, to conclude the project a joint customer day was held by the client and Galliford Try for local residents, where by the residents were invited to the works for a presentation of why the works were required and a tour of the new facilities.

Post-tensioned precast concrete FST tank – Courtesy of Galliford Try

Conclusion

The Cropwell Bishop STW contract (valued at £2.8m) started in January 2017 with the design phase running for 10 months. The construction phase was scheduled for 14 months between February 2018 and March 2019. The project completed in December 2018, three months ahead of schedule.