Boston Barrier Tidal Flood Defence Scheme (2021)

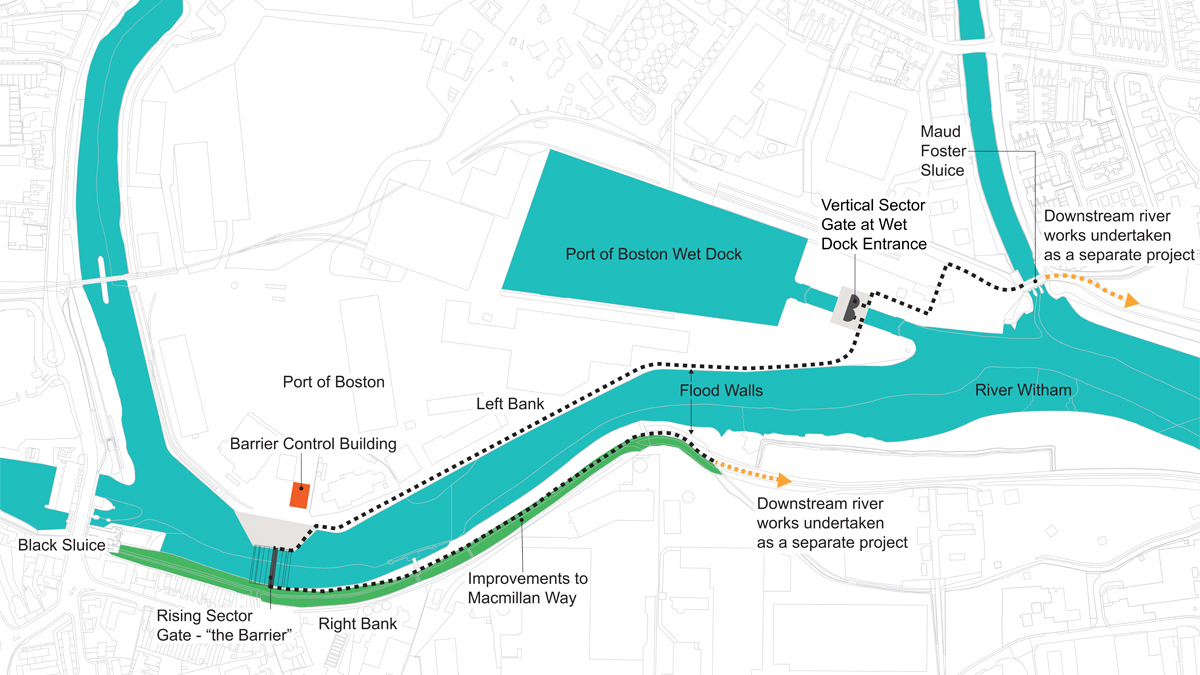

General arrangement of the Boston Barrier Scheme - Courtesy of Environment Agency

The Boston Barrier Tidal Flood Defence Scheme is a £100m project for the Environment Agency, delivered by BMMJV (a joint venture between BAM Nuttall and Mott MacDonald), to reduce the risk of tidal flooding to 14,300 properties and businesses in Boston, Lincolnshire. Boston is located on the east coast of the United Kingdom off The Wash and has a history of tidal surges. The project will reduce the risk of tidal flooding against an event of 1 in 300, or an annual exceedance probability of 0.33% of flooding for the 100 year project lifespan. The project was initially featured in UK Water Projects 2019 focussing on the design and early construction. This article aims to provide an update on construction progress as of July 2021, and is recommended to be read in conjunction with the previous article for project background information.

Construction updates

Rising sector gate and barrier structure

The barrier gate is a 362T, 28m wide and 11m high gate in the River Witham which can be raised and lowered prior to a tidal surge event to prevent inundation of the town with flood water. The gate is operated using two hydraulic rams, each weighing 56 tonnes. The barrier structure is formed from an innovative combination of precast curved recess panels grouted into the main in situ low-carbon concrete super-structure including pre-fabricated reinforcement cages and conventional bundled reinforcement.

The barrier gate was delivered in November 2019 from Holland and was driven into position from a barge onto the structure using a self-propelled modular transporter (SPMT), as shown below. The cellular bypass channel was then constructed and in-filled with the hydraulic pipework to the barrier reinstated at ground level. The barrier became fully operational in December 2020, providing flood protection to over 13,000 homes and businesses in Boston. This milestone contributed to 5% of the Environment Agency’s 6 year national target of better protecting 300,000 homes from flooding by March 2021.

(left) Delivery of the rising sector gate and (right) rising sector gate in operation – Courtesy of Environment Agency

Barrier control building

The barrier control building houses all the critical infrastructure required to operate the barrier, including the main power supply, hydraulic power pack, standby generator, and control room. The innovative design solution saw the main operational equipment moved from the ground floor to the first floor to ensure flood resilience was maintained should an event overtop the defences.

The building also incorporates solar panels on the roof and an air source heat pump to both minimise its operational energy consumption and reduce its overall carbon footprint over its design life. This will provide a year on year cost saving to the Environment Agency throughout its operational life and demonstrates the benefits of incorporating renewable energy solutions in major infrastructure projects.

Barrier control building – Courtesy of Environment Agency

Right Bank works

The Right Bank of the scheme is now substantially completed with a new river wall 525m long constructed from 19m long anchored sheet piles, including two emergency lay-by facilities for navigational vessels. The public footpath facing length of the wall includes both an in situ formed concrete panel depicting local maritime artwork defined through community engagement and precast concrete coping panels. Significant landscaping works have also been completed with propagation and reinstatement of the nationally rare Boston Horsetail, wildflower meadow mixes and improvements to the Macmillan Way to make it further accessible to people with restricted mobility over the length of the works.

In situ artworks on Right Bank flood wall – Courtesy of Environment Agency

Left Bank works

The Left Bank works were substantially complete in summer 2021. The Left Bank construction included a reinforced concrete flood wall, three load relieving platforms and a new outer quay wall. The quay wall is supported using steel tube anchor piles. The new quay wall is required to guarantee the 100 year design life of the flood wall and was designed with flexibility in the tubular anchors to accommodate any unforeseen below ground obstructions within the Port of Boston.

Marine furniture such as bollards and fendering have also been provided to enable the Port to operate from the outer quays whilst the wet dock entrance is temporarily closed. This has also included a fall arrest system, stairway installation to enable access to the outer quays over the new flood wall and low level and high level lighting.

(left) Piling at load relieving platform 3 – Courtesy of Environment Agency, (top right) completed left bank flood wall as viewed from the Right Bank and (bottom right) completed flood wall and Load Relieving Platform 3 along the Left Bank – Courtesy of BMMJV

Wet Dock Entrance

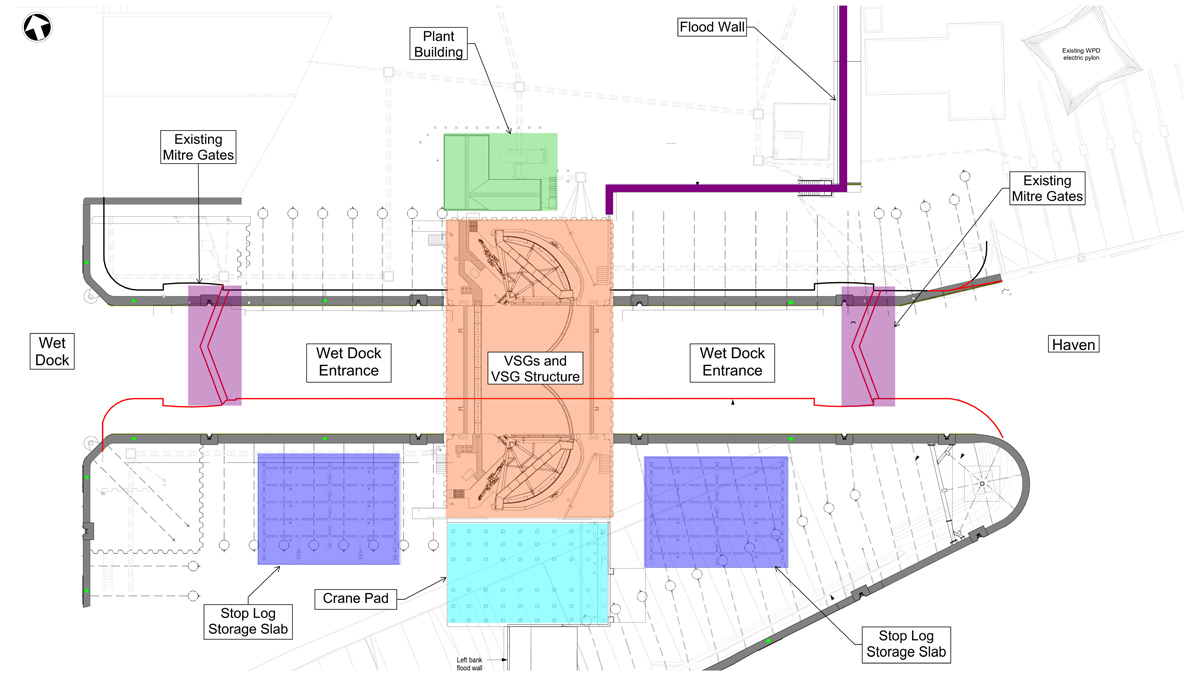

The Wet Dock Entrance (WDE) upgrade works focus on the existing lock and channel structure connecting the Port of Boston Wet Dock with the Haven. Two sets of existing timber mitre gates currently serve to maintain a minimum operational water level within the wet dock and shall be replaced as part of these upgrade works with a single set of vertical sector gates (VSGs). These VSGs will provide the required flood defence level across the WDE.

The VSGs, supplied by Hollandia Infra, are each 12m high and 9m wide and are operated by a set of hydraulic rams, supplied by Hunger Hydraulik, each weighing 6.5 tonnes. Gate operation is powered and controlled from a new WDE plant building, located adjacent to the VSG structure. As with the Barrier structure, precast concrete units will be utilised to form the ‘snail back’ profile of the VSG housing within the main VSG structure. The geometry of the VSG housing was informed by detailed computational fluid dynamics (CFD) analysis, using 3D models developed during the early design process. 3D modelling and other BIM tools were used extensively and to great effect in the design of both the cast in situ and precast elements of the VSG structure and to coordinate the various supplier designs with one another and the main structure.

General arrangement of wet dock entrance – Courtesy of BMMJV

The existing WDE channel will also be widened from 16 to 18m as part of the WDE works to allow for future passage of larger vessels. The widened channel profile will be formed using approximately 300m of sheet piled quay walls topped across the whole WDE with a reinforced concrete capping beam and restrained with anchor ties connected to tubular piles.

Rectangular sheet piled cells will be used as supporting structures at the WDE quay wall corner with the existing wet dock where clashes and congestion mean anchor ties and tubular piles are not feasible. With an 18m clear width a requirement of the design, bespoke, adaptable fender supports were designed to accommodate pile creep and any minor misalignment during installation.

The existing WDE floor slab will be replaced with a reinforced concrete base slab, protected against uplift through passive relief wells draining to an underlying granular drainage blanket and discharging to the WDE through multiple riser pipes along the channel length.

The existing wet dock relies on maintaining a minimum operational water level to preserve the structural integrity of the walls. As such, multiple layers of redundancy, including an emergency hydraulic power unit and an easily deployable winch system, have been supplied for VSG operation following exhaustive reliability studies and risk assessments of potential failure mechanisms.

Ongoing maintenance of the VSGs will be facilitated through the provision of 21 new, 18.5m wide bespoke stoplogs which will be supplied and permanently stored adjacent to the VSG structure and which can be used to isolate the VSG structure from the surrounding WDE channel. Once complete, these will be one of the largest sets of stoplogs in the country. To place the stoplogs, a piled crane pad will be constructed adjacent to the storage racks to provide a safe working platform for crane operations.

(left) BIM model render of the wet dock entrance vertical sector gates and structure – Courtesy of BMMJV, (top right) shipping the VSGs across the North Sea and (bottom right unloading the VSGs at the Port of Boston – Courtesy of Hollandia Infra

A reinforced concrete flood wall will complete the site’s continuous flood defence and extends from the Left Bank to the VSG structure and then northwards to tie into the exiting Maud Foster Sluice, a Grade 2 listed historic structure. The flood wall is a ground bearing structure and incorporates a 2m deep cut-off sheet piled wall tied into the flood wall toe which provides additional protection against seepage.

On the quayside north of the WDE channel, access through the flood wall is provided via a 10m sliding flood gate. A second sliding gate 6m wide provides access through the new flood wall on the southside of the WDE channel to the WDE knuckle structure. Both sliding gates have been supplied by Flood Control International.

Construction activities within the WDE will be completed in dry conditions, facilitated by two HZM sheet pile walls at the upstream and downstream extents of the channel. A further temporary cofferdam will also be installed in the middle of the channel to allow for construction of the VSG structure and installation of the VSGs which will also form part of the permanent works similar to the primary gate piers. Following construction completion, the HZM piles at either end of the WDE will be cut-off to provide scour protection to the WDE base slab in the permanent case.

During construction, wet dock operations will be temporarily moved to the outer quays, where load relieving platforms have been installed. A temporary dolphin structure has been installed within the river channel to support vessel turning and was determined through work with the Port of Boston and HR Wallingford.

Turning dolphin in the river channel – Courtesy of Environment Agency

Boston Barrier: Supply chain – key participants

- Project delivery: BMMJV

- Bam Nuttall

- Mott MacDonald

- Client advisor: Jacobs

- Client technical representative for barrier gate and associated equipment: KGAL Consulting Engineers Ltd

- Gate & hydraulics Cat 3 checker: Eadon Consulting

- Rising sector gate design and supply: Hollandia Infra

- Hydraulic ram supplier: Hunger Hydraulik

- Hydraulic system supplier: Industrial & Marine Hydraulics (IMH)

- Sliding flood gates: Flood Control International

Project innovations and successes

Carbon emission reductions

Reducing carbon emissions has been an important consideration for the scheme and some key examples of how this has been achieved during project delivery are:

- The concrete mix for the barrier structure incorporates 70% ground-granulated blast furnace slag (GGBS), a by-product of the iron industry, as a cement replacement. The use of GGBS saved a total of 1,246 tonnes of carbon emissions across the 6,000m3 of concrete required in the barrier structure.

- Inverting the design concept of the barrier plant and control room to position all essential plant on the first floor achieved the required level of operational resilience against flooding without needing to waterproof the entire structure. This removed the requirement for piled foundations to provide resistance against uplift and enabled the deletion of 70 piles. Key benefits were a significant reduction in buried obstruction risk, reduction of 360 tonnes of embodied carbon and savings of £300,000.

- Use of precast concrete elements to form the dish shaped gate recess negated the need for a bespoke single-use 200 tonne in situ steel shutter.

Contribution of the Boston Barrier project to UN SDG sub-goals. The height of the bar indicates the significance of the positive impact towards each goal – Courtesy of Mott MacDonald

Sustainable outcomes

The Boston Barrier is the first major construction project undertaken by the Environment Agency to map project outcomes against the United Nations Sustainable Development Goals (UN SDGs). The Boston Barrier Scheme delivers benefits against all 17 UN SDGs and 25 specific sub-goals. The image below shows the 25 sub-goals that the project provides benefits against. A full evidence list of the project’s contributions can be found in a published paper Boston Tidal Barrier: Adapting to Climate Change and Delivering Social Outcomes (Pollard, Thompson, Robinson et al., 2021).

Award wins

The Boston Barrier Scheme has received external recognition for its innovative approaches on sustainability and digital delivery. The project has been awarded the following award wins:

The Boston Barrier Scheme award nominations and wins