High Frequency Risk Reduction: Garstang Road (2021)

Aerial view of site, showing tunnel launch and reception pit layout - Courtesy of United Utilities and Advance-plus

In the PR19 agreement, water companies were encouraged to provide resolution to long-standing flooding problems being experienced by customers – but allowed a less prescriptive approach on the actual projects defined in the Water Company’s (WCo’s) Price Review submission. This new process allowed WCo’s a degree of discretion on the number and frequency of flooding areas to be addressed in the AMP7 period and provided an incentive in resolving flooded areas based on when in the AMP they were delivered. This article provides a technical and engineering focussed precis of one of United Utilities’ early start ‘High Frequency Risk Reduction’ (HFFR) projects located at Garstang Road, Bilsborrow, and the factors that were considered in delivering this relatively complex and fast-tracked project.

Background

The overall programme of flood alleviation projects to be delivered by United Utilities during AMP7 is entitled ‘High Frequency Risk Reduction’ (HFFR). The purpose of the programme is to resolve long standing (decades in many cases) issues experienced by residents that previously had been overlooked or not deemed sufficiently high enough priority to be included in previous flooding investment programmes.

The HFRR selection process was based on several factors including frequency of flooding experienced, number of properties affected and whether the flooding was internal or external in nature. It is worthy of note that previous flood impact assessments had often resulted in reduced priority being given to the resolution of external flooding events, whereas the HFFR assessment output generally concluded these events to be almost as traumatic as internal flooding especially when the frequency was high.

Garstang Road flooding

Garstang Road, Bilsborrow, is located approximately 6 miles north of Preston and is a heavily trafficked section of the main A6 carriageway which passes north-south through Lancashire and into Cumbria. There are numerous residential and commercial developments along Garstang Road and adjoining spurs in the Bilsborrow area, many of which have been in existence for over 100 years.

(left) The tunnel drive and (right) Herrenknecht TBM cutting head – Courtesy of United Utilities & Advance-plus

Project need

Historical flooding has routinely occurred along Garstang Road primarily considered to be due to the topography of the surrounding rural area. Unfortunately, this resulted most notably in three commercial properties experiencing both internal and external flooding over many prior years. These properties were two public house with attached accommodation and a bed and breakfast establishment that has been established in a property that dates back to the 16th century.

The HFFR assessment identified the project need and the urgency of flood alleviation measures required based primarily on the frequency of reported events.

Solution development

Extensive hydraulic modelling was undertaken by United Utilities and its AMP7 Construction Delivery Partner, Advance Plus JV, to understand the root cause of the flooding and subsequently identify and develop potential solutions to resolve the issues. Initially a deep shaft-type storage tank was proposed where surcharged waters could spill into the tank and be returned via pumping to the existing network following abatement of the storm event. A tank of approximately 750m3 was required, together with associated connecting pipework.

This initial solution was proposed to be located within the grounds of the affected public house, however more detailed development of the solution identified an alternative option for a fully gravity operated system, where surcharge levels would spill over a weir into a concrete storage tank and then be released, via gravity, back to the network. This option would have the advantage of not requiring pumps and associated mechanical and electrical equipment, thereby reducing operating costs. Hydraulic and network modelling highlighted that the new storage tank would have to operate within the hydraulic head of the surcharged sewers and the flood level, a band of only 3.07m and top water level in the tank only 380mm below the gully/cover levels in the road where flooding would occur.

Launch pit prepared for first drive – Courtesy of United Utilities and Advance-plus

Due to the limitation of available hydraulic head, the only suitable location for the tank was in an adjacent agricultural field between the A6 Garstang Road and the C350, Bilsborrow Lane. Land access and acquisition negotiations with the landowner commenced and were productive and amicable. The project was on track to deliver a successful outcome.

At the start of the project implementation phase, this solitary oak was not seen as a significant obstacle in the design development of the storage tank. However, it quickly became apparent during wider stakeholder engagement that the solitary oak was held in high regard and affection by the local community. The situation quickly came to the attention of the local authority who concluded that, even in consideration of the overall project need and benefits, removal of the oak would not be acceptable – and promptly imposed a Tree Preservation Order. The required project delivery date of 31 March 2021 was now at risk of being missed.

A complete re-evaluation of the design was undertaken to assess alternative options for the storage tank. Relocation of the tank within the confines of the field footprint whilst avoiding the oak was not feasible. It became clear that the only alternative was to go under the tree and provide the necessary stormwater storage volume by means of a tunnelled solution.

Tunnelled solution

Development of the tunnelled solution to provide the 750m3 storage needed, concluded that twin 1.8m diameter pipes approximately 90m long would be required. Additionally, two 9m diameter shafts would also be required, one at either end of the pipe sections to act as the launch-pit and the reception-pit for the tunnel boring machine (TBM) to be utilised for the sub-surface works.

Launch pit tunnels completed – Courtesy of United Utilities and Advance-plus

High Frequency Risk Reduction: Garstang Road: Supply chain – key participants

- Principal contractor: Advance-plus JV

- Civil design: COWI

- MEICA design: Stantec UK

- Geotechnical investigation: Geotechnics Ltd

- Tunnelling: Joseph Gallagher Ltd

- Tunnel boring machine: Herrenknecht

- Pipe laying: W&B Civil Engineering

- Level instrument: Technolog Ltd

- Mechanical installation: Stal (UK) Ltd

- 1800mm ID main tunnel pipes: FP McCann Ltd

Construction overview

Advance Plus JV engaged sub-contractor (Joseph Gallagher Ltd) to install both the tunnels and the TBM launch and reception shafts. Construction works commenced in December 2020 with the tunnels and shaft installed using the following main plant and equipment:

- Herrenknecht full-face 1800 (ID) AVN TBM 2160 TBM.

- 120/40T crawler crane.

- 250T mobile crane.

- 34T telescopic grab.

- 20T and 5T excavators.

- Separation plant and centrifuge/desander.

- Compressor, generator (1260/300kVA) and ventilation.

The main tunnel pipes were provided by FP McCann Ltd at 1800mm internal diameter.

Construction timeline

Both shafts were sunk between 7 December 2020 and 10 February 2021. The TBM was delivered to site on 20 January 2021 and after set-up and commissioning, commenced the first drive on 9 February 2021. This drive took approximately 11 days to complete, after which it was returned to the launch-pit to commence Tunnel 2 on 27 February 2021 and took a further nine days to complete this drive.

Tunnelling and pipeline construction was undertaken on a 12-hour shift basis working 7 days per week. Overall, the tunnel drive was successful with few issues encountered. The main challenge was the variability of the geological conditions along the route. At the launch shaft the ground was a stiff clay with medium to coarse sands with occasional cobbles and sandstone boulders. This changed to a medium density silty sand and gravel towards the reception shaft.

Herrenknecht TBM Kelly – Courtesy of United Utilities and Advance-plus

The stiff clays proved more difficult to drive through with only 2-3 pipes installed per shift, whereas through the silty/sand layer the progress achieved installation of six pipes per shift; in total 32 pipes were required for each tunnel drive. Fortunately, the water table was below the TBM outside face, hence dealing with ingress of groundwater was not a major concern on either drive.

Settlement along the line of the tunnel was carefully monitored, however as the works were located within a field, the impact on overhead structures was not a significant issue. The main limitation identified was allowable settlement below the solitary oak tree; this was set at a maximum of 30mm (the tunnel was approximately 6m below the ground level at this location).

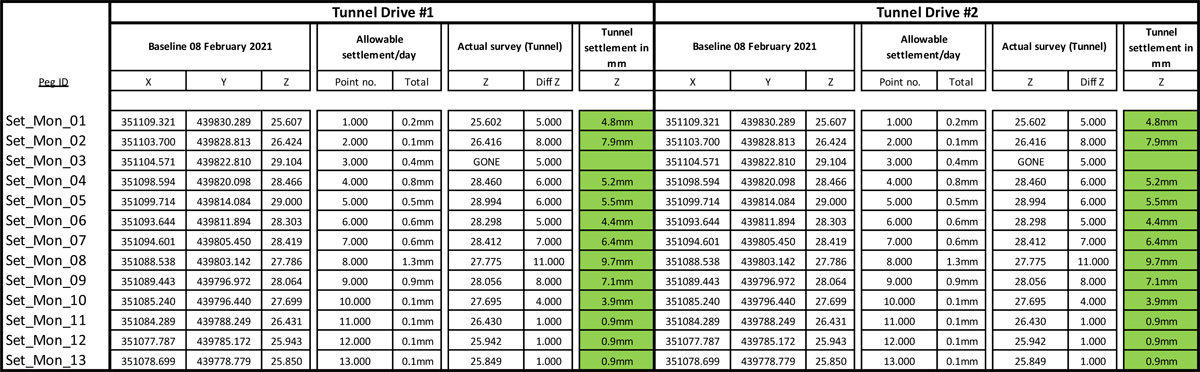

Monitoring undertaken along each tunnel drive showed settlement of 6.7mm and 9.7mm respectively, well within the tolerance allowed and this had negligible impact on the oak tree’s stability.

Ground settlement values along tunnel

Completion of construction works and the initial phase of field reinstatement progressed to programme during March 2021. Installation and commissioning of the Storm Event Detection system, level monitoring instrumentation and telemetry interfacing was then successfully completed in readiness for the Project Output In Use date of 31st March 2021.

Project summary & outcome

Delivery of the Garstang Road High Frequency Risk Reduction Project posed several key challenges. These challenges were predominantly related to:

- Maintenance of unaffected service level to United Utilities’ customers in the local area during project implementation.

- The identification of a suitable storage tank solution to match the prevailing sewer network hydraulic profile.

- The selection of the storage tank location to minimise local community impact during construction works.

- Achieving a challenging delivery programme to meet regulatory commitments.

- Ensuring stakeholder consultation and community engagement during all phases of the project.

- A solitary oak tree which unwittingly promoted the completely aligned collaboration across the whole project team and showed the results which are achievable when this happens.

One mighty oak to be protected – Courtesy of United Utilities and Advance-plus

The positive impact and success of the project on the affected flood risk properties was immediately evident. At time of writing, there have been no flood events have occurred in the Garstang Road area since introduction of the new storage tank system, despite a series of significant storm events occurring in the period April-June 2021.