Audley Borehole Pumping Station (2018)

(top left) Existing main control panel, (top right) sampling room, (bottom left) chlorination panel and (bottom right) Seprol outstation - Courtesy of Severn Trent Water

Audley Borehole Pumping Station is one of Severn Trent Water’s (STW) borehole capital maintenance projects which supports the Peckforton Group in supplying potable water to Coopers Green Reservoir. As part of the £3m scheme, the project focuses on delivering resilience from Audley to maintain high quality water supply to the people in Staffordshire. Audley is the first borehole site in STW to be refurbished and the design and construction of Audley Borehole Pumping Station will enhance reliability and reduce operational expenditure (OPEX) and maintenance through its lifetime.

Background

Detailed feasibility analysis shows that a potential borehole outage at Audley will reduce 20% of the total output in the Peckforton Group network. At the same time, Coopers Green Reservoir is operating on average less than 60% capacity and the Peckforton Group network is prone to low levels especially in periods of high demand if a borehole outage occurs.

Audley is critical to the operation of the Peckforton Group because it is the final chlorine dosing point where all the abstracted water from Peckforton, Towers Wood, Tattenhall and Audley are residual trimmed before arriving at Coopers Green Reservoir.

The Audley rehabilitation project which coincides with the variable speed drive (VSD) upgrades at Peckforton, Towers Wood and Tattenhall will allow an automated response to the blending at Coopers Green Reservoir to improve the future security of supply from the sources.

It has been identified that the existing borehole pumps and motor control centre (MCC) have reached the end of their asset life. The design and build contractor Mott MacDonald Bentley (MMB) has been appointed by Severn Trent to deliver the rehabilitation project where the drilling of a new borehole (No. 3) will provide backup resilience to supply water to Coopers Green Reservoir whilst the existing boreholes are refurbished. When the new borehole is operational, MMB will take boreholes No. 1 and No. 2 out of service and refurbish all the associated mechanical and electrical equipment to the client’s specification.

Scope

The main scope of the detailed design services includes:

- Design of a new 415V low voltage (LV) switchgear including 3 (No.) VSD starters.

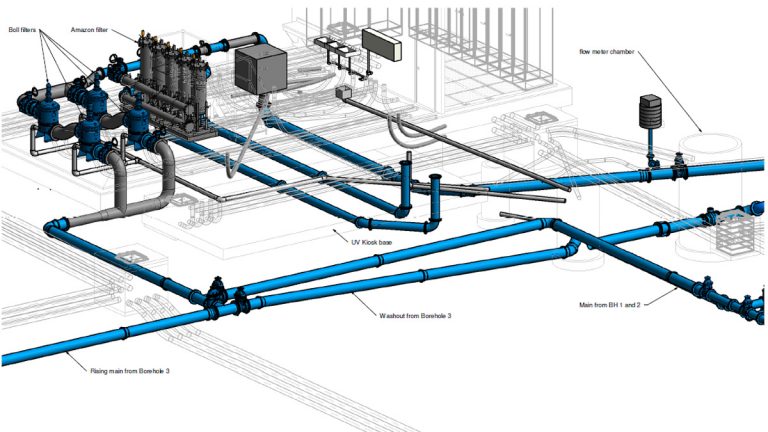

- Design of a new temporary filtration system which comprises 2 (No.) 50-micron Bollfilters, 2 (No.) 10-micron Bollfilters from Bollfilter UK Ltd and 1 (No.) 5-micron filter skid supplied by Amazon Filters Ltd.

- Supply 3 (No.) new 180 kW borehole pumps.

- Design of a new mains/generator changeover panel.

- Temporary installation of a new UV treatment plant from Trojan Technologies.

- Replacement of existing 2 (No.) motive water pumps.

Bollfilter and Amazon installation – Courtesy of Mott MacDonald Bentley

Key aspects

Configuration and layout: There has been careful consideration by the design team to maximise the usable space within the control room. The design team proposed a L-shaped arrangement which provided wide open space for maintenance and improved fire escape accessibility.

Suspended mezzanine floor design: A new suspended mezzanine floor design brought more additional space to allow service pipes and cables to safely pass between the existing main building and the control room kiosk.

The design was created as a 3D model on Revit and the software demonstrated that there were no clashes between the ducts beneath the suspended flooring. This enabled an easy visual representation for both the designer and contractor to exploit any existing ducts underground and provide future cabling.

Temporary filtration design: The design team developed an automated filtration control which supports the construction team during the drilling phase thereby guaranteeing safe drinking water by preventing sand and silt particles flowing into the water supply.

The temporary filtration equipment is designed to be removed and reused on future borehole sites once the drilling has been complete. The ethos of reusing equipment will promote significant cost savings in Severn Trent’s long-term goal of delivering future borehole capital maintenance schemes.

Cable duct and site pipework 3D design – Courtesy of Mott MacDonald Bentley

Smarter control and visual screen: User-friendly human machine interface (HMI) is introduced within the new MCC which allows the operator to respond to equipment failures quickly through the access to the HMI mimic screen. The operator can select a variety of functions to deliver water to avoid peak tariffs and triad periods providing massive cost savings towards STW’s electricity bill.

Turbidity control is one of the main features developed by the design team where it minimises sand disturbance during the borehole ramp-up sequence. This benefit has allowed borehole pumps to slowly ramp up their speed and maintain its speed for a set time until the turbidity safely drops below an appropriate set-point so to avoid nuisance tripping on the fail-safe shutdown control panel.

Additional features such as level control, flow control and time clock control are also incorporated within the programmable logic controller (PLC) to provide a proactive system to respond rapidly to different types of scenarios and maintain water supply continuously to Coopers Green Reservoir.

Redesign of mains/generator changeover panel: Early collaboration between the design team and the framework supplier encouraged a bespoke design to fit the mains/generator changeover panel in a precise location within the existing main building. Clash of existing equipment and restriction of height were avoided by carefully planning around the building layout whilst providing safe clearance access for future maintenance.

Mains/generator changeover panel – Courtesy of Mott MacDonald Bentley

Electrical instrumentation: In the original arrangement, the electrical instruments monitored combined flow data from the borehole pumping station.

Now with the new borehole upgrades, the design team will deliver individual level, pressure and flow monitors on each borehole pump to provide constant data monitoring on all the borehole instrumentation which enables Severn Trent to analyse and create predictive maintenance on their equipment.

In addition, this will enable Severn Trent to flexibly adjust their parameters at Peckforton, Towers Wood, Tattenhall and Audley to offer more output to Coopers Green Reservoir.

Water quality monitors were installed at every stage of the treatment process. This provided a detailed insight on the turbidity readings before and after the temporary filtration system where the team can observe and monitor the quality of water to Coopers Green Reservoir maintaining a high level of quality control to the Staffordshire area.

Challenges

Legacy telemetry outstation: The design and commissioning team ensured the telemetry signals from the legacy telemetry outstation were migrated carefully over to a new outstation. Attention to detail by the site team ensured that no telemetry signals were lost during the transitional period where critical signals were identified and tested to the client’s standard. This had minimised the downtime of the electrical equipment and successfully interfaced with the new LV switchgear.

Integrating with existing equipment: The existing motive water pumps were situated within a confined space area. The construction team replaced 2 (No.) motive water pumps inside the new kiosk building and brought the mechanical and electrical equipment above ground for ease of maintenance.

This allowed MMB to safely integrate the old and new equipment and to ensure the entire critical process equipment is performing smoothly which at the same time eliminated future confined space work.

Network intervention: Critical shutdowns to the water supply were crucial to ensure the mechanical and electrical equipment were installed and completed within the allocated timeframe. Consistent collaboration between the site team and the networks intervention team ensured minimum delays to the installation and commissioning of the LV switchgear.

Current status

At the time of writing (May 2018) the mechanical and electrical detailed designs for Audley Borehole Pumping Station are complete. The MCC and the associated equipment have been delivered, installed and commissioned. It is estimated that the entire mechanical & electrical installation will be complete by 2019.