Ballygowan WwTW (2023)

The new Ballygowan WwTW (March 2023) - Courtesy of NI Water

Ballygowan is a small village situated in County Down, within the Ards & North Down Borough Council area. The towns of Comber and Saintfield are both approximately 4 miles to the north-east, and to the south respectively, with the city of Belfast 7 miles north-west. The 2021 Census indicates that the population of Ballygowan is approximately 3,138. The existing WwTW was constructed in the village in the 1950s and comprised an inlet works, a CAS basin, a storm tank and a small sludge holding tank, as well as an MCC building to control the works and was designed to treat a population equivalent (PE) of 2,700. The existing works was therefore beyond capacity to treat the present day population, and the structures had exceeded their design life. An extensive upgrade was required to provide effective and robust wastewater treatment services for the future catchment area, allowing economic growth, while improving the local environment and adhering to a much tighter discharge consent of 7mg/l BOD, 10mg/l total suspended solids, and 1.5mg/l ammonia. The new fully automated works will serve a PE of 4,513.

Primary drivers for the upgrade

- The existing wastewater treatment works (WwTW) was undersized for the current flows coming into the works.

- The existing works was not complaint with the Northern Ireland Environment Agency’s discharge consent standard for Ballygowan WwTW.

- Future planning applications for residential properties in the Ballygowan area had been put on hold due to the existing WwTW operating beyond its intended design capacity.

- The existing works was not capable of fulfilling the requirements of NI Water’s long-term strategy to enhance wastewater services and ensure environmental compliance and was expensive to operate and maintain.

- An even tighter NIEA standard was imminent.

(left) Existing Ballygowan WwTW – Courtesy of NI Water and (right) demolition in progress: (top) the existing storm tank and (bottom) the existing CAS basin tank – Courtesy of GEDA Construction

Project description & scope

Designed for a 2045 population equivalent of 4,500, the new Combined Activated Sludge Plant (CASP) at Ballygowan WwTW, was to be constructed east of Dickson Park in Ballygowan, in a green field site that bordered the southern boundary of the existing site:

- The preliminary treatment process comprising of 6mm inlet screening and forward flow-control equivalent to Formula ‘A’.

- A new storm storage management facility including a CSO storage tank, and two storm tanks providing a total capacity of 224m3. The CSO storage tank and two storm tanks are equipped with a tipping bucket system for effective cleaning of the storm tank floor.

- Flows equivalent to Full Flow to Treatment (FFT) are pumped forward via a new interstage pumping station.

- FFT is then split with equal flows going to two CAS basin tanks. The selector chamber was carefully designed to assist with controlling filamentous bulking in activated sludge systems which can be a common operational challenge issue in activated sludge plants.

- Downsteam of the flow split chamber, there are two CAS tanks complete with final settlement tanks (FSTs) accommodated centrally, each aeration stream comprising of an anoxic zone to aid denitrification, and three individual aeration zones equipped with tapered aeration diffuser grids. The design and construction of the biological treatment process on this site was critical and to ensure compliance with an extremely stringent discharge consent of 1 mg/l ammonia alkaline was dosed at this stage in the process, detailed below.

- Due to the restricted footprint available for the site, the CAS tanks were selected to accommodate the final settlement stage within the biological treatment footprint. Two FSTs were constructed, with the CAS (anoxic and aeration zones) wrapped around the FSTs.

CAS basins – Courtesy of NI Water

- Following final settlement, the treated effluent gravitates to a tertiary treatment plant for further solids removal prior to discharge at the final effluent outfall location.

- A new combined RAS/SAS pumping station was constructed adjacent to the selector/flow split chamber to aid best use of available footprint. This pumping station houses two RAS pumps to replenish the bacteria within the biological treatment system and maintain the required MLSS levels for effective treatment. A further two SAS pumps are also provided to pump away sludge to the new sludge storage facilities should the MLSS levels within the treatment process exceed the desired levels.

- The new Ballygowan WwTW includes two sludge storage tanks, one mechanical sludge thickener and a polymer chemical dosing plant for processing sludge prior to being tankered offsite.

- To ensure a robust solution was provided for the client to meet the 1 mg/l ammonia consent, a supplementary alkalinity chemical dosing plant was provided for dosing into the aeration lanes. The provision of this dosing plant which utilises sodium carbonate ensures there is sufficient alkalinity available within the biological treatment process for effective and complete nitrification under all flow and load conditions.

- The works also comprises a new MCC room which controls all mechanical and electrical plant equipment and instrumentation, a welfare unit, a standby backup generator, and associated access and drainage.

- As the treatment works was built in close proximity to a neighbouring residential area, the odour model highlighted areas of the treatment process that required covers with passive odour abatement being provided.

- The site was also landscaped to include a site bund to reduce the visual impact on the neighbouring residential area of Dickson Park.

New storm tank being utilised during construction – Courtesy of GEDA Construction

Main challenges for design/construction

Discharge consent

The key challenge around the design and construction of the new Ballygowan WwTW, was ensuring that the new WwTW would comply with a very tight water order consent (WOC) set by NIEA. The WOC is one of the tightest consents in Northern Ireland. The discharge consent was originally advised as 7:10:1.5 mg/L (BOD/TSS/ammonia), however the design and construction was further challenged when NIEA confirmed that the ammonia consent would be restricted to 1mg/l ammonia. GEDA Construction, in conjunction with their MEICA and process subcontractor Water Solutions Ireland Ltd, reviewed the design and construction proposal to provide a solution which incorporated minimal changes, minimising costs to NI Water, but still providing effluent treatment compliance.

Site location

The WwTW site is bordered by agricultural land to the north and east, and has a housing development to the west. To construct the new WwTW and keep the existing plant operational, NI Water purchased an area of land (formerly a football pitch) to the south of the site belonging to the local council. The existing WwTW access road is through Dickson Park housing estate and runs directly alongside a children’s playpark. In advance of construction the project team took the proactive decision to look at creating a temporary construction access to the south of the site through agricultural land so that all construction traffic would not have to travel near Dickson Park or the children’s playpark. Extensive consultation took place with local landowners, the residents’ association and roads authority and the temporary road was successfully constructed ahead of construction start.

Due to the close proximity of the new WwTW to the housing development, consideration was also given to any potential visual and odour implications to the neighbouring housing development. It was decided at an early stage to design the structures in such a way that they would have minimal visual impact. This meant designing and constructing structures as low in the ground as possible to keep them out of view of the neighbouring properties. An earth bund was also constructed to the west boundary of the site and planted with trees/bushes and shrubs in order to further hide the treatment works as well as helping to combat any odours coming from the site.

Ballygowan WwTW under construction (December 2021) – Courtesy of NI Water

Interface between new and old works during construction

The majority of the new WwTW works was to be built on a greenfield site which allowed GEDA Construction to build most of the new structures without having to work around existing infrastructure.

However, in order to construct pipelines which would eventually take the flow into the new works, and to construct the new WwTW access road, it was necessary to demolish the existing storm tank in the old works prior to the new works becoming live. GEDA Construction carried these works out by utilising the newly-constructed storm tank and incorporating a carefully developed phasing plan.

A temporary 300mm gravity fed sewer was laid from the existing inlet works to the new storm tank, which in turn rendered the existing storm tank surplus to requirements, as all storm flows had been diverted away from it. GEDA Construction also had to lay a temporary 200mm pumped sewer from the new storm tank complete with temporary pumps to send the storm flows back to the existing pumping station in order for the influent to then go through the treatment process. This in turn allowed us to demolish the existing storm tank and construct the new permanent inlet sewers to the new works ahead of turning flows. This process had to be carefully managed both hydraulically and biologically to ensure the treatment process was optimised and effluent compliance was maintained at all times.

New permanent high-level sewer under construction – Courtesy of GEDA Construction

Turn of flows

Influent flows were successfully diverted into the new works in early May 2022. In order to bring the new biological treatment process online, several tanker loads of seeded sludge were brought to site from another treatment facility and were introduced into the new CAS basin tanks to promote bacteria growth. With flows diverted, and effective treatment established through a rigorous sampling regime, approval was received from NI Water to proceed with the demolition of the remainder of the existing treatment works. Once the existing works were decommissioned and demolished, the entire new WwTW site was able to be finished and access roads completed.

Demolition

Post turn of flows in early May 2022, the existing treatment works was decommissioned and then demolished. Reusable mechanical and electrical assets from the old treatment process were removed for future use by NI Water, while the effluent left in the old CAS basin and pumping station was removed from the site to allow demolition to commence. Effluent was filtered through the new treatment process to minimise unnecessary removal and disposal from site.

Project team

As principal contractor, GEDA Construction had overall responsibility to deliver the project on time and within budget, which they succeeded in doing by working collaboratively with NI Water, project managers Tetra Tech, key suppliers and subcontractors to identify and plan for key project milestones.

McAdam provided civil, structural and geotechnical design services, including the initial enabling and investigatory works carried out at the Early Contractor Involvement (ECI) stage, as well as the detailed design for construction. Water Solutions Ireland (WSI) were responsible for designing and delivering a full turnkey MEICA, process design and build solution for the new works.

Ballygowan WwTW: Supply chain – key participants

- Civil contractor: GEDA Construction

- Project managers: Tetra Tech

- MEICA contractor: Water Solutions Ireland

- Civil, structural & geotechnical design: McAdam

- Electrical design: SBE Design

- Mechanical design: McWall Drawing & Design

- PLC software & commissioning: Ashdale Engineering

- Odour control: Anua Clean Air UK

- Storm screens: Eliquo Hydrok Ltd

- Grit removal plant: Jacopa

- 6mm inlet screening: Hydro International (M and N Electrical and Mechanical Services)

- Aeration blowers: Aerzen Machines

- MCC: Greenville IDC

- Pumps, mixers, fine bubble diffusers: Xylem Water Solutions

- Tertiary treatment plant: WPL

- Chemical dosing: Richard Alan Engineering

- Instrumentation: Park Electrical Systems

- Flow measurement: Siris Environmental Ltd

- Flow measurement: AMPM Flow & Energy Services Ltd

- Penstocks, valves & actuators: Flow Technology Services

- Storm tank cleaning tipping bucket: CSO Group Ltd

- GRP kiosks, FST scrapers & site-wide metalwork: Victoria Engineering

- 6mm bar screen, skip rails & trolleys: Graham Steelwork Engineering

- Potable & FE service water boosters: Dutypoint Ltd

- Lifting equipment: Columbus McKinnon Co Ltd

- Solar panels & EV charger: Solmatix Renewables Ltd

CAS basins in operation – Courtesy of NI Water

Solar

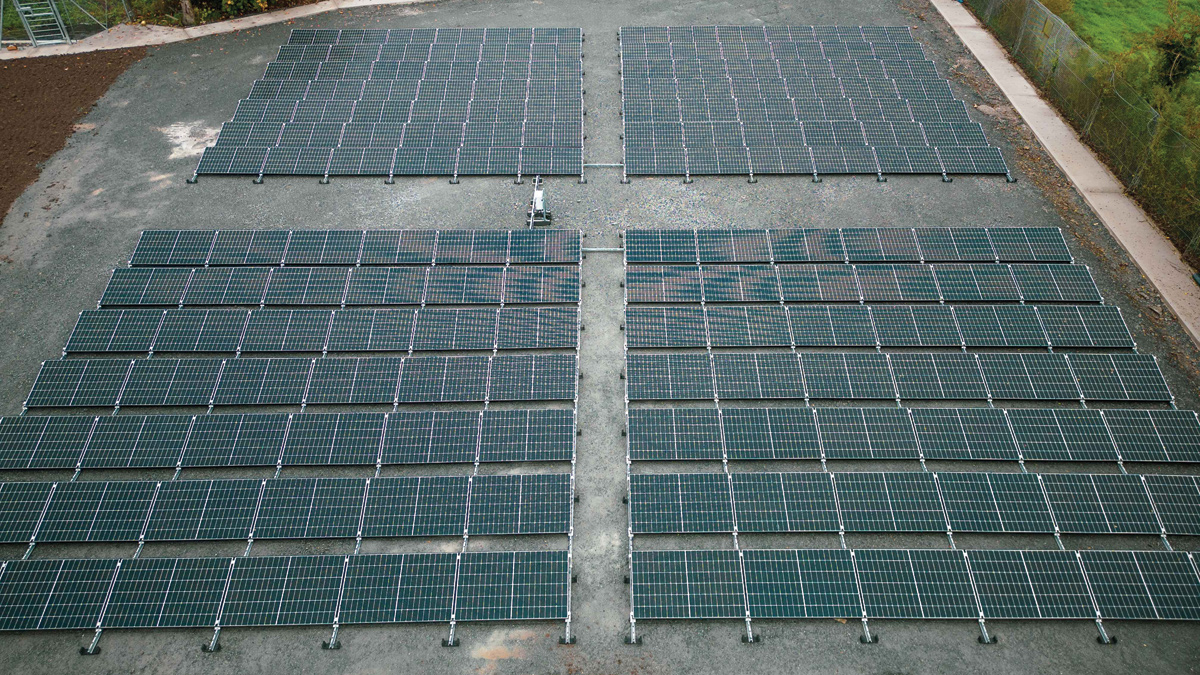

It was recognised that a large area of land within the footprint of the existing WwTW site would be available for use following demolition of old structures. As a result, NI Water asked GEDA Construction and Water Solutions Ireland to investigate the feasibility of installing solar energy within the space available.

Following a successful outcome of the feasibility study, it recommended that a 62Kw solar PV array would be installed in the free space which would provide renewable energy to run some of the WwTW operations and boost the sustainability of the site. A 22KW dual EV charger unit was also installed which is used by NI Water’s growing fleet of electric vans.

Solmatix Renewables Ltd installed a ground-mounted solar PV panel system consisting of 164 solar panels within the footprint of the old works. New electrical invertors and controls housed within the new MCC kiosk were installed and cabled directly onto the new MCC.

The solar system has been set up as zero export, meaning everything that is being generated on site, is used on site through the plant and other electrical equipment. The estimated payback period on NI Water’s £70k investment is 6.5 years (savings of £11,000/year on electricity costs at Ballygowan WwTW).

Solmatix Renewables Ltd solar farm – Courtesy of NI Water

Alkalinity

A challenging issue encountered during the design and construction of the new works at Ballygowan WwTW was the high acidic nature of the incoming influent. During review of the design and aided by a sampling regime of the influent under varying flow conditions, it was determined the site required alkalinity dosing to allow the wastewater treatment process to provide adequate nitrification (in other words ammonia reduction) within the biological treatment to meet the 1mg/l ammonia discharge consent.

This problem required NI Water and GEDA Construction to design, supply, install and commission a supplementary packaged chemical dosing system to increase the alkalinity levels and achieve a stable pH within the wastewater to safeguard optimum treatment.

NI Water shared some past negative experiences encountered with similar alkalinity dosing plants which was invaluable to ensure that a well thought out, comprehensive solution was selected, which would deliver the requirements of supplementary dosing but reduce the ongoing operation and maintenance requirements encountered on other schemes for NI Water. The agreed solution was to provide a new proprietary sodium carbonate (powder) make up and dosing system, all housed within its own GRP kiosk and standalone control panel.

Odour control

Due to the proximity of nearby residential housing, the design and execution of odour containment and treatment was a major consideration for this project. Early odour models and specialist supplier engagement was imperative to ascertain the potential effects of odours. GEDA Construction provided a cost-effective, proven solution through a carbon filter plant dedicated for the inlet screening and grit removal works, and a second Mónashell Biofilter plant from Anua Clean Air UK was provided solely for the sludge treatment and storage tanks. Both systems, along with covering large areas of the works with solid top flooring, safeguard against the negative effect odours can cause.

Ballygowan WwTW nearing completion – Courtesy of NI Water

Collaboration and PR

Collaboration was instilled throughout every aspect of the planning, design and construction phases for the new Ballygowan WwTW. NI Water and its project management team developed a proactive communication and PR strategy for project which included erection of storyboards; circulation of project brochure; issuing of regular updates to residents; briefings for elected representatives; circulation of press releases and a number of events and initiatives with the local residents’ association. A collaboration initiated with the local council also saw the creation of a small orchard by local children on an area of disused council land adjacent to the WwTW, which GEDA prepared for planting out.

Outcome

By working in partnership with each other, as well as myriad stakeholders, NI Water, Tetra Tech, GEDA Construction and the wider supply chain were able to successfully overcome difficult challenges to deliver a sustainable, state-of-the-art wastewater treatment solution, capable of meeting its stringent consent standard and serving the community for many years to come.

(left) Cleared strip adjacent to playpark, (top right) community orchard planting, and (bottom right) the Ballygowan project team preparing winter planters for the village with members of the local residents’ association - Courtesy of NI Water