Blymhill STW (2016)

Aerated reed bed - Courtesy of Mott MacDonald Bentley Ltd

Blymhill STW is a small rural RBC and reed bed STW based in south Staffordshire which treats flows from a PE of about 551. This was set to increase to a design population of 844 PE due to predicted non-residential domestic load. The catchment consists of several individual villages, plus the non-domestic contribution from Weston Park (a very popular country house with cafe, hotel, conference centre, restaurant which hosts many events, including venue of the ‘V’ Pop festival (60,000 visitors per day) and West Midlands Game Fair etc). As a consequence, incoming flows and loads can vary greatly depending on the events which are held in the local area. The treatment was conventional and consisted of a RBC followed by combined reed bed treatment before flows were discharged to a local stream. This article demonstrates how managing Severn Trent Water’s business risk and collaborative planning can influence design and construction between asset creation, design and build partner and whole sale operatives.

Background

The existing catchment comprises of 5 (No.) small sewage pumping stations (SPS) with four of these pumping into the gravity system that feeds the works. The other SPS feeds directly to the works. The existing consent was 223m3/d DWF, 15 mg/l BOD, 25 mg/l SS and 5/10mg/l NH3 (summer/winter).

There were several problems at Blymhill which needed to be addressed:

- The 2 (No.) RBCs were hydraulically and biologically over-loaded (design PE 444 only), causing blockage due to carbonaceous bacterial growth in the reed beds. This resulted in significant compliance problems on ammonia. Although multiple root causes were suspected, clearly the increased domestic contribution from Weston Park’s increasing events calendar contributed. The flows from the major events (pop festivals etc) were tankered away but the general facilities were expected to see much greater use during these times. Previously, service delivery routinely tankered out at significant cost (~£43k/yr) from the site to intercept non-compliant flows. Between July 2011 and June 2012, non-compliant effluent was tankered away on 91 of the 267 days monitored.

- As well as the RBCs hindering the process, the combined reed beds were also hydraulically and organically overloaded and were also undersized (614m2) for the design population of this works.

- The inlet works was very crude and inaccurate and consisted of a small chamber which split the flows between the 2 (No.) RBC units with the aid of an in-laid brick wall. The structure itself had several trial and error modifications to even out the flow split and remove the original storm overflow route which were unsuccessful

- Inaccurate proportional flow splitting between existing reed beds of differing surface areas.

Aerated reed bed – Courtesy of Mott MacDonald Bentley Ltd

Risk mitigation

Blymhill was failing frequently and by a large magnitude on ammonia from an unknown source. These spikes were so excessive that the biological process did not have time to adapt to them. Because of the sites size, to find the source of this problem would have required extensive investigation, and once found could not be guaranteed to stop the issue.

In addition the ammonia spikes were combined with highly fluctuating crude flows, making it difficult to size process units accurately. As such the site design was approached with a phased and flexible solution. The site would be adaptive, acting on the ammonia spike when they occurred.

Because of the dimensional restriction and cost involved with designing the site to meet the maximum ammonia spike in the traditional way, an alternative method was used involving a balancing tank, aerated reed beds, and an ammonia monitor, maximising the attenuation of the process stream.

This not only provided an excellent solution (no consent failure since commissioning) but allowed the site to be flexible and adaptive, reducing both TOTEX and OPEX, saving capital to allow both Mott MacDonald Bentley (MMB) and Severn Trent Water (STW) to focus their efforts on other projects.

Aerated reed bed – Courtesy of Mott MacDonald Bentley Ltd

Ammonia treatment

The use of aerated reed beds was something new to Severn Trent Water, Blymhill being only the second site owned by STW to have them. Aeration of the reed beds provides additional oxygen to the process stream allowing the bacteria to thrive and in turn aiding the removal of ammonia within the reed beds. This allowed the site to meet the ammonia consent without the need of any further process units.

TOTEX and space limitations required an adaptive control system. During normal flows conditions, the flows pass through the RBC then onto the reed beds before passing through the ammonia monitor.

In event of an ammonia spike the flow is diverted to the balancing tank by actuated valves. This enhances the attenuation and allows tankers to remove the worst of the non-compliant effluent. Once this is removed the flows passed through the RBC and back into reed beds continuing on the original process path.

The final installed solution to address all issues was as follows:

- New inlet chamber arrangement to accommodate a new storm overflow, weir splitter and actuated penstock.

- A new flow split chamber to Reed Bed 1 and the reed bed feed pumping station (RBFPS).

- Relocation of the existing NH3 monitor to FE chamber.

- Refurbishment the existing reed beds and installation of a new aeration system.

- Conversion of existing clarifier tank to act as a buffer tank.

- Installation a new MCC and kiosk to control the whole site process.

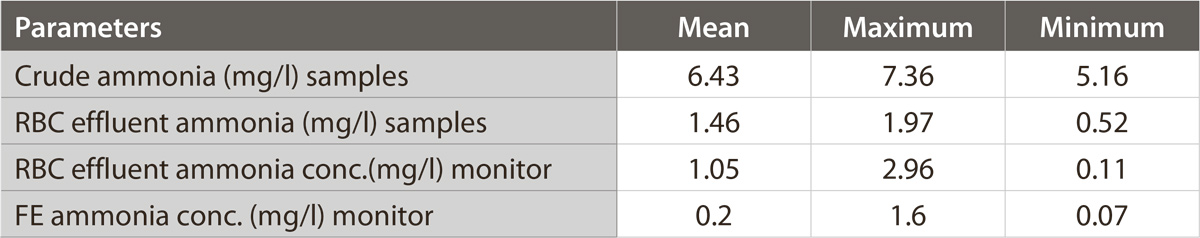

Post-install ammonia performance data

Collaborative working

In addition to the technical innovations installed on site, this project displayed benefits of how working closely with asset creation and PDE can yield significant results even when faced with adverse conditions.

During the construction phase a high ammonia spike brought work to a halt. However, by working closely with all parties involved, a plan was devised to control the disruptions. Without this close communication and interaction with all parties involved, the scheme could have easily failed to be delivered effectively and within the agreed timeframe due to communication breakdown.

Clearly communicating targets and using outstanding works log enabled the client to understand when and why delays were occurring. This lead to a great understanding relationship enabling any design changes that were required to be done quickly and effectively. Despite the delay in the construction phase MMB was credited with the excellent handling of the project.

Recently commissioned aerated reed bed – Courtesy of Mott MacDonald Bentley Ltd

AMP6 efficiency tools

With the help of new AMP6 efficiency tools, collaborative planning was used to keep all involved parties engaged and ensure further work and handover processes got delivered successfully.

All AMP6 efficiency levers were used. Alongside strategic planning, product development was set in place and standard products were used where possible in order to shorten the programme and save time on construction.

The site also utilised alternative technologies such as three way valves to enhance the efficiency of the pipework layout. Production control was implemented in order to manage areas of large impact. This was done by use of event notices, plan to protect tools and early third party involvement.

Another aspect that ensured the smooth and successful delivery of the Blymhill STW project was the interaction between the design and construction teams. Being a design and build company, MMB managed to deliver an effective and integral solution which could have only been achieved by close communication and interaction between both the traditional arms of the company, office and site.

Balancing tank pipework – Courtesy of Mott MacDonald Bentley Ltd

Conclusion

Working and communicating closely with everyone benefitted not only this project but future projects as well. The relationships forged helped build on the already strong bond MMB has with clients. This is key to a successful prosperous AMP with Severn Trent.

While failure to address all the risks and issues of a project is recognised within this industry, another issue not commonly talked about is over-engineered projects. This can be just as detrimental to both the client and contractor as it can deplete time and funds which would could have been ultilised more effectively on other projects.

Allowing flexibility at Blymhill STW by utilising a business risk register enabled the correct solution to be delivered to Severn Trent.