IIES (Northern) Ltd

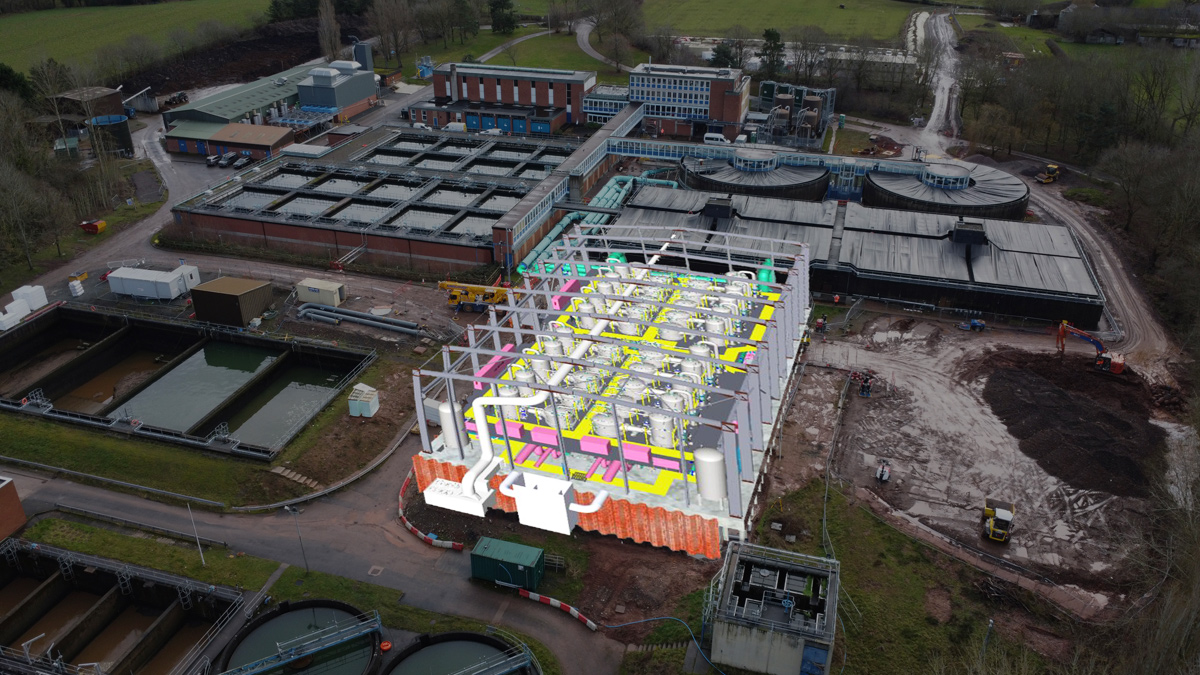

IIES (Northern) was established in 1985 as an ICA, electrical and mechanical engineering company generally serving the water industry as a specialist chemical dosing provider. Since then we have developed into a multi-disciplined project engineering company involved in all aspects of engineering with the majority of our business still water related. The company has been engaged and responsible for successful delivery of over 1800 projects in our markets.

IIES has a formidable record of completing outstanding projects in the water treatment industry for over 40 years which support strict environment and regulatory compliance requirements, all backed up with management systems accreditation in ISO:9001, ISO:14001 and ISO:45001. We are also certified on Achilles UVDB, Construction Line, ECA and are an approved contractor on NICEIC.

Our core capability encompasses the following:

CHEMICAL DOSING & TECHNICAL CONSULTANCY

- Site surveys

- 3D scanning available

- Process investigation

- Process recommendations

- Compliance with standards & specifications

MANUFACTURE & INSTALLATION

- Plastic fabrication

- Plastic cutting

- Plastic welding

- Chemical dosing systems

- Chemical dosing rigs

- Bunds/drip trays

- Kiosks & enclosures

- Electrical installation

- NICEIC approved contractor

- Control & instrumentation cabling

- Pipework installation

- Fusion welding

- Delivery and offloading

- Site installation

MEICA DESIGN

Mechanical

-

- Process instrumentation & piping diagram

- Process calculations

- Full site general arrangements

- Equipment general arrangements

- Schedules and standards

- Full operation & maintenance manuals

Electrical

-

- Process and systems control philosophies

- Cable block diagrams

- Schedules

- Electrical installation to BS7671

- Test and inspection to BS7671

- Electrical certification NICEIC approved

- Member of the ECA

Control

-

- Panel design

- FDS

- Panel schematics

- System Integration

- PLC software

- HMI software

- SCADA integration

- Telemetry integration

- Panel design

COMMISSIONING & SITE PROCESS SET-UP

- System setup

- Pressure testing

- Electrical installation testing

- Electrical certification (NICEIC)

- Servicing & maintenance

- Telemetry & SCADA

OTHER SPECIALIST AREAS

- Control panel specification

- P & ID development

- Front end design & feasibility

- Capital/revenue budget costing

- Equipment specifications

- Detailed design & construction packages

- Project management

- Operating & maintenance documents

- Principal contractor

- Offsite testing

- Development of plant layouts

- Process & equipment specifications

From initial client briefing a basis of design, including site surveys as necessary, will be carefully prepared and reviewed and will be developed further through detailed specifications and arrangement drawings.

Our experienced engineers can provide comprehensive installation design for a variety of process plant and equipment, handling hazardous bulk chemicals in liquid, gaseous or solid form and in extreme conditions. Technical review and support will be provided to the client throughout the development cycle.