Finham Advanced Anaerobic Digestion (2023)

Finham STW Advanced Digestion Plant - Courtesy of Costain

Finham STW, situated near Coventry in the West Midlands, is Severn Trent’s fifth largest wastewater treatment works and treats over 115 megalitres of effluent a day from half a million people. The works processes indigenous sludge on site as well as accepting exports from local, satellite sites, producing final effluent, ‘cake’ and biogas as outputs. The two separate elements at Finham comprised a Thermal Hydrolysis Plant (THP) and a Gas to Grid (G2G) project, which were delivered as a single advanced digestion scheme. Sludge is anaerobically digested to produce biogas which, prior to the advanced digestion scheme, powered two, 60-cylinder, combined heat and power (CHP) engines providing recirculated heat for digestion and electricity for the works. Following a competitive tender, the design and build contract for the purpose-built, brand-new, advanced digestion scheme was awarded to Costain by Severn Trent in 2019, with construction starting on site in early 2020.

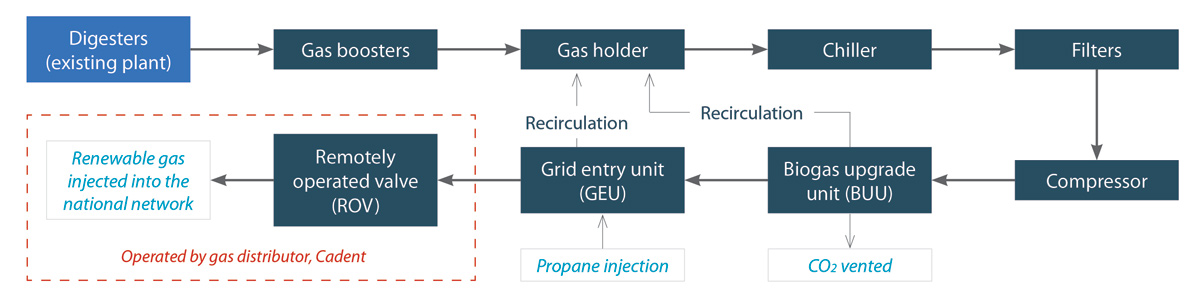

Overview – Gas to Grid Project

The gas to grid (G2G) phase of works refines biogas from the digesters through a biogas upgrade unit (BUU) and blends it with propane to ensure the correct calorific value for export to the national gas grid. This phase was complete first with a sectional completion date of March 2021, determined by the Ofgem industrial Renewable Heat Incentive (RHI) scheme deadline.

The first export of biogas to the Cadent Gas Network was successfully delivered by the key milestone and ensured that Severn Trent secured RHI-funded unit rate for its gas export.

Gas to grid process diagram – Courtesy of Costain

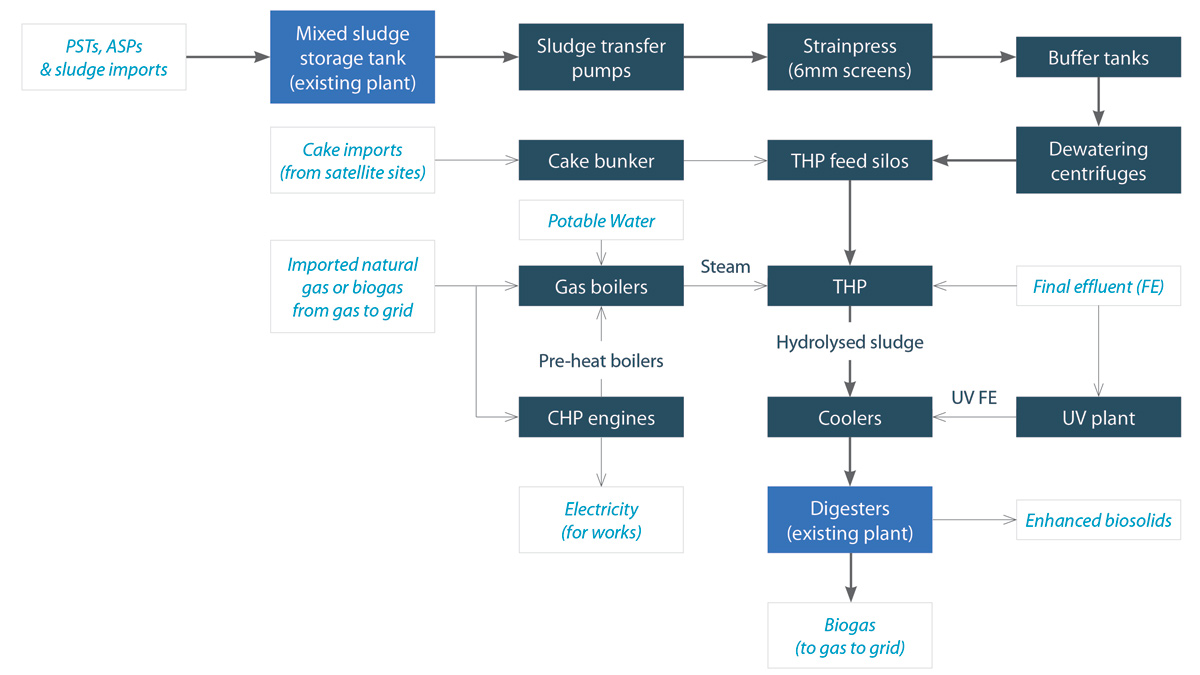

Overview – Thermal Hydrolysis Plant

The thermal hydrolysis plant (THP) phase of the project was around 75% of the total value of the scheme and constructed alongside the G2G initially, before continuing to completion once the G2G section was handed over.

The process utilises a Cambi Ltd designed THP which uses steam from two-gas boilers to hydrolyse sludge produced by the primary settlement tanks (PSTs), activated sludge plant (ASP) and imported sludge from regional sewage works around the midlands. This process increases the gas yield of the sludge when digested to increase G2G throughput. Process commissioning started in January 2022 and contractual completion was in July 2022.

Thermal hydrolysis plant process diagram – Courtesy of Costain

Gas to Grid Project

Digesters, boosters and gas holder

Biogas is produced by sludge digesting in 8 (No.) digesters on site. The pressure is regulated in each digester with a ‘floating roof’ which rises and falls with the volume of gas present. The project saw 6 (No.) boosters installed, 3 (No.) 1000m3/hr boosters to transfer the biogas from the digesters into the gas holder between 15-25mBar and 3 (No.) to provide a biogas feed to the boilers.

A 2700m3 inflatable gas holder was constructed on a 400t concrete suspended slab to store biogas and provide the BUU with a consistent flow and pressure of gas.

BUU, GEU and ROV

The biogas upgrade unit (BUU) uses membrane technology to refine the biogas and export it to the grid. The BUU was procured from Italy and required careful management to navigate the international challenges posed by COVID-19 and Brexit. The BUU has a throughput flow rate of 720m3/h to 1800m3/hr. The upgraded gas is then sent through the grid entry unit (GEU) which monitors the characteristics of the gas and rejects non-compliant gas.

The compliant gas is then exported to the gas grid through the remote operated valve (ROV) kiosk which is operated by the gas utility, Cadent, down 800m of newly laid medium pressure gas main in the highway which was installed using horizontal directional drilling (HDD) to minimise impact to the public.

(left) Inflated gas holder and (right) biogas upgrade unit and carbon storage silos – Courtesy of Costain

Thermal Hydrolysis Plant

Sludge

The THP process uses a blended mixture of sludge from surplus activated sludge (SAS) from the aeration settlement plant (ASP), primary sludge from the primary settlement tanks (PSTs) and liquid imports from satellite sewage works. Sludge ‘cake’ is also imported into the new THP cake bunker where it feeds directly into the THP silos. The blended sludge is transferred by progressive cavity pumps via 2 (No.) duty/duty 220m long buried sludge mains.

Screening

The transferred sludge is screened through 3 (No.) Huber Technology Strainpresses with 6mm screens that capture and remove solids in the sludge to prevent wear and tear damage to the THP process. Screenings are dropped from the elevated platform into 2 (No.) roll-on-roll-off skips ready for incineration off site. The elevated strain presses were craned onto the steel frame which was assembled in 3 days. The screened sludge in then moved into two, 1200m3 buffer tanks that keep the sludge moving to prevent settlement before it is dewatered.

(left) Sludge transfer pumps and (right) elevated strain press in front of the buffer tanks – Courtesy of Costain

Dewatering

The screened sludge is dewatered from approximately 3% to 20% dry solids for transfer to the THP feed silos. 3 (No.) centrifuges work in a duty/duty/standby arrangement and backwash with final effluent (FE) as required.

THP & boilers

The cake is diluted with FE to 16% dry solids and fed into one of the 2 (No.) THP streams which process up to a maximum of 60 tonnes of dry solids per day (tds/day) per stream.

The sludge is heated to around 95°C in pulper to become ‘homogenised’. This sludge is then pumped sequentially through each of the streams 4 (No.) reactors for batch treatment. Steam from the boilers is used to heat the sludge between 50-180°C where it is held at 6-bar pressure to undergo pasteurising hydrolysis for around 30-45 minutes. After hydrolysis, sludge is passed into the flash tank, where the pressure and temperature of the hydrolysed sludge are decreased by flashing steam back to the pulper. The flashtank provides the necessary thermal buffer capacity to release the excess energy contained in the sludge before entering the downstream pumps.

The process kills all pathogens and, in turn, increases the potential gas yield of the sludge.

2 (No.) boilers, procured from Italy, produce 192°C steam from potable water, operate at 12bar and can run on either natural gas imported from the grid or biogas produced from the gas to grid plant. 2 (No.) CHP engines are situated locally to the boilers and the exhaust gas heat is recovered by boilers to optimise performance, these CHP engines can also run on either natural or biogas. The boilers are operated by BOAS accredited operators who were transitioned across from Costain to Severn Trent upon handover.

The warm hydrolysed sludge is then blended with UV FE to reduce the temperature to around 42°C where it is fed back into the digesters via a bank of 8 (No.) sludge return pipes traversing 500m across the site footprint.

(top left) Centrifuges, (top right) THP silos, (bottom left) the boiler and (bottom right) the boiler house – Courtesy of Costain

UV treatment and sludge cake

A UV plant was constructed to ensure no pathogens were introduced to the sludge post-THP which would normally be present in non-UV treated FE. This ensures that the biosolids product produced by the works is ‘enhanced’ quality and can be sold to farmers to fertilise fields growing a wider range of crops than those which can have ‘standard’ biosolids. A pair of Bollfilters with 25µm strainers from Bollfilter UK Ltd screen the FE prior to UV treatment to ensure that stringent disinfection standards are achieved and to prevent particulates damage to the plant.

Other THP highlights

The THP installation also included a polymer dosing plant, FE and potable break tanks, odour control unit, deep drainage and centrate pump stations with 700m of buried return pipework to head of works, a new FE pump station and a 1200m3 cake bunker.

THP reactors – Courtesy of Costain

Finham STW Advanced Digestion Plant: Supply chain – key participants

- Design & build: Costain

- Geotechnical investigation: Geotechnics Ltd

- Digester to G2G pipework: Alpha Plus Ltd

- Gas import/export pipe: Morland Utilities Ltd

- Mechanical installation: HL Engineering Contractors Ltd

- FE pump station: Arthur Civil Engineering Ltd

- G2G mechanical installation: Field System Design Ltd

- Pre-THP mechanical installation: Balmoral Ltd

- LV electrical installation: AVRS Systems

- Roads: Hercules Site Services

- Groundworks & FRC: Costain

- Trace heating & lagging: Thermal Design Ltd

- Thermal hydrolysis plant (THP): Cambi Ltd

- Biogas upgrade unit: Air Liquide UK Ltd

- Odour control unit: Air-Water Treatments Ltd

- Bollfilters: Bollfilter UK Ltd

- Gas holder: Power Plastics Ltd

- Centrifuges: Alfa Laval Ltd

- Buffer tanks: Balmoral Tanks Ltd

- MCCs, controls, switchboards etc: CEMA Ltd

- CTM imported cake reception silos & hoppers: CTM Systems Ltd

- GRP kiosks: Industrial GRP Ltd

- UV pathogen control: Lintott Control Systems Ltd

- Lightning protection & earthing: Omega Red Group

- Grid entry unit (GEU): Orbital Gas Systems

- Polymer storage & anti-foam dosing: Richard Alan Engineering Ltd

- Indigenous sludge screens: Huber Technology

- Indigenous buffer tanks air mixing: Stem Drive Ltd

- Lifting equipment: T Allen Engineering Services Ltd

- Steam boilers: Thorne Industrial Boiler Services

- Flare & G2G boosters: Uniflare Ltd

- Boiler & THP operational support: PBJ Engineering Services Ltd

Construction

The vast proportion of the civil installation was self-delivered, this allowed for flexibility in the installation programme to align with constantly changing delivery and subcontract dates affected by COVID-19 and material shortages. The delivery team consisted of over 100 operatives at its peak, covering a range of trades. The construction phase included the installation of over 3.4km of buried drainage, 3 (No.) cofferdams and over 200 crane lifts.

The mechanical plant was largely designed for manufacture and assembly (DfMA) off site and was able to be delivered, lifted in and installed in a relativity short period of time. One of the highlights was the installation of the 175 tonne THP which was installed in 10 working days.

(left) Cake bunker cofferdam and (right) cake bunker – Courtesy of Costain

Health & safety

The safe delivery of the project was extremely successful and managing the interface between multiple contractors working in a small footprint was priority throughout. The delivery and commissioning phase saw over 490,000 hours worked with a AFR (Accident Frequency Rate per 100,000 hours worked) of 0.00. A total of 2,315 different people contributed to the scheme and over 3,200 hazard and safety observations were raised.

The design team were proactive in holding hazard and operability (HAZOP) reviews with the client from the outset of the project, using the integrated 3D design model to identify potential challenges in a virtual environment prior to construction.

Due to the volatile nature of substances on site, stringent safety measures were adopted in line with the Dangerous Substances and Explosive Atmospheres Regulations 2002 (DSEAR). Procedures put in place during G2G commissioning and handover benefitted from cross-sector learning and Costain specialists from the Energy sector helped shape the measures put implemented.

CHP engines- Courtesy of Costain

Commissioning and handover

Commissioning of the G2G took place in 2021 with the first export to the grid in March 2021 before the Government’s commercial RHI deadline. The gas quality standard is set by the end user, Cadent, who dictate a specific calorific value that the gas must be for export.

This is monitored by the grid entry unit (GEU) which recirculates non-compliant gas back to the gas holder to be refined further. This refining process was complex and required close collaboration between the client and contractor. The gas to grid achieved sectional handover to the client first and was taken over whilst construction continued the THP.

The THP was commissioned in 2022 and required complex commissioning to convert the digesters from conventional sludge to hydrolysed sludge. This was done in a phased approached, whilst closely monitoring the biology of the digesters, over the course of 3½ months. The health of the digesters directly impacts the sludge feed rate through continued monitoring of several factors including % dry solids, pH, ammonia content etc.

Biodiversity

Planning conditions set out a requirement to create a mitigation area to enable net gain in biodiversity on the Finham site. The client’s solution was to establish a wildflower meadow at least equal in area to the new hardstanding constructed to promote a thriving insect and wildlife environment. Whilst Severn Trent were considering the logistics and cost of how to fulfil the planning requirements, Costain’s self-delivery team were busy excavating over 15,000 tonnes of muck for the THP build.

Muck shift in progress – Courtesy of Costain

Costain worked collaboratively with Severn Trent to draft plans for the reuse of the muck in the proposed BIA and began the process of sampling and testing the muck. A comprehensive Materials Management Plan approved under the CL:AIRE regulations was produced detailing the proposal. Upon approval from all parties, the muck shift operation began. Costain operated three 30 tonne articulated dumpers (ADTs) to transport the muck across the site. Each dumper averaged 25 trips per day and the full operation was completed in just a little under two weeks.

The overall benefits were:

- 15,000t of waste product eliminated.

- No requirement for Severn Trent to import material.

- Net saving after labour and plant costs.

- Reduced carbon emissions by 76.2 tonnes.

- Reduced road traffic by up to 1000 lorry journeys.

- Site participation in World Environment Day.

- Contractor/client collaboration and mutual benefit.

- Long lasting environmental legacy.

Finham THP & G2G – Courtesy of Costain

Project awards

The advanced digestion project has been nominated for several construction awards including the Constructing Excellence Sustainability Award, the Pipeline Industries Guild Award, and was successful in winning the NEC Sustainability & Climate Resilience of the Year award 2021.

Department for Business, Energy & Industrial Strategy (BEIS) also visited the project during its construction to showcase the Government’s investment in domestic, renewable energy generation.