Gouthwaite Reservoir (2024)

Installing the drawdown siphons at Gouthwaite Reservoir - Courtesy of Jifmar Group

Gouthwaite Dam impounds the River Nidd on its route from the head of Nidderdale, North Yorkshire, and is the last in a cascade of three reservoirs within the valley; those upstream being Angram and Scar House. The Category “A” Dam was constructed between 1893 and 1901. The project undertaken by Mott MacDonald Bentley (MMB) on behalf of Yorkshire Water was for the construction of a new reservoir drawdown siphon pipe with a hydraulic capacity of 13,500 l/s to allow the water level in Yorkshire Water’s second largest reservoir to be lowered by 5m in 5 days in the event of an emergency, following best practice and guidance from the appointed Qualified Civil Engineer (QCE).

Background to the project

In 2017 (AMP 6), MMB was contracted to produce an acceptable design and construction of the downstream leg of the siphon. In 2021 (AMP 7), MMB resumed works, assessing opportunities in a period of detailed design, with construction of the upstream and crest elements of the siphon commencing in November 2022.

Design

The additional outflow capacity required to achieve a 5m drawdown after five days with a Q10 inflow was confirmed during the 2017 concept design phase to be achievable by installing a siphon. The hydraulic design of the siphon was acceptable to the QCE. The design of the siphon inlet was required to prevent the development of air-core vortices forming at the inlet end of the siphon at levels approaching 5m below Top Water Level (TWL). This was achieved by ensuring the inlet of the siphon was suitably submerged, with a 3m x 3m bar cage proposed, with a solid roof situated on suitable rock armour.

The design constraints within the reservoir related to the ground profile, which is normally below water. To map the profile, a bathymetric survey was undertaken by APEM Ltd to ascertain the surface profile, with a sub-bottom profiling survey (silt survey) also undertaken by APEM to understand the potential levels of soft, silty material on the reservoir bed.

Pontoon excavator – Courtesy of Mott MacDonald Bentley

The design of the upstream leg of the siphon included a 70m length of 2000mm Ø flanged steel pipework leading from the inlet to the crest, with excavation of the reservoir bed to install at the designed depth necessary to attain the required submergence depth of the inlet end of the siphon. Excavated material could then be utilised as backfill and provide sufficient resistance to thrust forces about bends near the crest. Prior to passing through the crest, the siphon tapers from 2000mm Ø to 1600mm Ø.

The constraints through the crest of the dam were with respect to minimising the impact to the earth embankment dam and the overflow channel downstream of the gravity dam. The level of the siphon through the crest were dictated by the hydraulics of the siphon, with the horizontal alignment of the pipe such that it was sat on the concrete core, some of which required removal, of the earth embankment dam. The vacuum pump priming system, air release pipework and 1600mm Ø isolation valve was positioned within the crest, with the siphon proceeding downstream towards an actuated gate valve installed just prior to the discharge location into the spilling basin, with the route taking consideration into its proximity to, and level of, the existing right-hand overflow collection channel.

Enabling works

With the dam sited along the River Nidd, one of the major challenges of the scheme was the extent to which the reservoir could be drawn down, given the compensation flow requirements required to provide a constant feed to a downstream fish farm throughout the year. There is little to no control of inflow into the reservoir, with the compensation pipework being the only means of draining it down.

Offloading pipes – Courtesy of Mott MacDonald Bentley

Any drawdown required a variety of factors to be assessed; the catchment is very ‘flashy’ with levels directly associated to rainfall in the large catchment. Any drawdown needed to be low enough to provide protection to the crest works within the cofferdam and beach area for pipe construction, but not too low that pontoons may ground out. With works programmed over a 16-month construction period, designs had to consider periods of very dry and very wet weather, whereby a drop in reservoir levels would see the crane unable to service the pontoon, and an increase in them leading to the in-reservoir works area being flooded out. A 2.7m drawdown was calculated and agreed with the client and other stakeholders, prior to being implemented in March 2023.

The drawdown provides 1-in-5-year storm protection without the reservoir overflowing, whilst retaining 50% of the reservoir’s water stock to be used at compensation flows, which feed the downstream fish farm.

A temporary pumping arrangement was also installed, the primary use of which being to draw off clean water from the top of the reservoir to maintain compensation flows should siltation be an issue when installing the siphon within the reservoir basin. The pumps and bagging were situated on a purpose-build pontoon cited 200m behind the dam, with flows discharged into the existing spillway channel. The pumps could also be utilised to assist in the drawdown of the reservoir as required.

Given the water level fluctuation, a means of isolation from the reservoir to the works within the crest was required to facilitate construction and protect the embankment during site works. A cofferdam was designed to protect the crest from up to a 1-in-1000-year storm event, allowing the site team to carry out works even when the reservoir is at top water level. The design had to be flexible, given that the concrete base and chamber were to be installed within it, alongside the large 1600mm Ø pipework and gate valve.

Cofferdam installation around the concrete core – Courtesy of Mott MacDonald Bentley

Working closely with Groundforce, MMB assessed different phases of the work and how the cofferdam could be optimised to suit construction requirements. The existing concrete core was utilised in the design to resist frame loadings throughout, alongside whilst the bottom frame was designed to be removed following the casting of the slab to facilitate further construction of the siphon.

Alongside frequent reviews with Groundforce, MMB undertook internal reviews for the cofferdam, highlighting possible failure mode, such as frame rotation, slope stability and the strength of the concrete core, implementing additional design checks and site to ensure a safe and effective design that could be constructed and maintained on site.

The project has aimed to minimise the impact of the enabling works by incorporating them into the permanent works where possible. It was proposed to install an area on the beach of the reservoir once it had drawn down to facilitate the forming of the upstream pipework and to position a crane, which could be utilised to lift pipes and equipment onto the pontoon. A ramp from the crest to the beach was installed using reclaimed stone from another scheme, which shall be retained for future maintenance purposes, reducing 1500T of muckaway from the site and reducing the number of vehicle movements.

The placement of a crane within the reservoir as opposed to on the crest reduced loadings on the embankment, as well as mitigating potential access issues to the remainder of the site. Embodied carbon within the scheme has also been reduced by utilising surplus stone from the site compound to construct the permanent vehicular access to the downstream valve, further reducing imported materials, alongside ensuring careful removal of wave wall masonry and stone pitchings, to ensure that they can be reinstated, maintaining the heritage of the structure.

Installation of the large diameter siphon pipes – Courtesy of Mott MacDonald Bentley

Surveys and previous workings within the reservoir had encountered peaty soils, which would require excavation prior to the installation of the upstream leg of the siphon. A silt mitigation plan was compiled by MMB with input from Yorkshire Water, the Environment Agency and Jifmar Group; the specialist marine subcontractor undertaking the in-reservoir works. Physical measures taken to contain silt included the installation dual silt curtains anchored to the bed of the reservoir, with an additional curtain installed around this.

Monitoring points installed in three locations by Meteor Communications Ltd provided real-time readings of pH, turbidity and dissolved oxygen, enabling out of hours remote monitoring/alarms and reducing the need for people and water interface. Text alerts were sent to the project team when readings exceeded those denoted in the silt mitigation plan, with MMB and Yorkshire Water operatives undertaking agreed actions and tests dependent upon the works being undertaken at the time (enabling works, low-risk and high-risk).

Installation of the large diameter siphon pipes – Courtesy of Mott MacDonald Bentley

Gouthwaite Reservoir: Supply chain – key participants

- Design & build: Mott MacDonald Bentley

- Bathymetric survey & silt survey: APEM Ltd

- Silt monitoring: Meteor Communications Ltd

- Upstream pipework installation methodology: Jifmar Group

- Cofferdam: Groundforce

- Piling: Sheet Piling (UK) Ltd

- Siphon pipework: Powerrun Pipe-Mech Ltd

- Siphon pipework: Freeflow Pipesystems

- Divers/pipework installation: Jifmar Group

- Valves: AVK (Supplied by Glenfield Invicta)

- Actuators: AUMA Actuators Ltd

- Air release pipework: Dax Air Ltd

- Site electrics & power: Total Automation & Power

- Kiosk: Morgan Marine

Construction

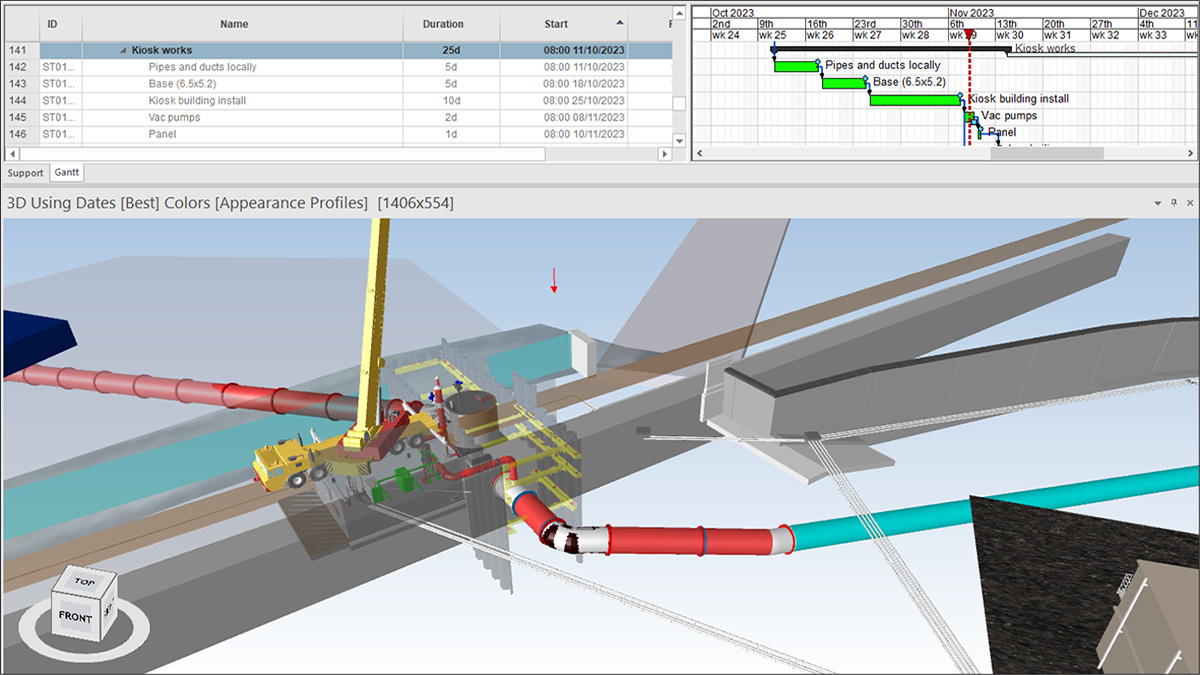

MMB mobilised to site in November 2022, with the crest and downstream siphon leg constructed by JN Bentley, and the in-reservoir works subcontracted to Jifmar Group. At this stage, collaborative planning sessions and Synchro software were utilised to enable teams to visualise the scale of the project and highlight potential programme clashes, driving efficiencies within the scheme from the offset.

Screenshot of Synchro software showing workings around the crest – Courtesy of Mott MacDonald Bentley

Having drawn down the reservoir, the silt curtains were installed, and the beach area utilised to accommodate the lifting pad for the crane and pipework storage. A pontoon was lifted in, with a 35T long-reach excavator positioned on it to commence excavations within the reservoir. As this was undertaken, the 2000mm Ø pipe assembly was joined together on the beach, complete with buoyancy aids to ensure the pipe would not sink should reservoir levels rise. Once both elements were completed, the pipe was floated out into position and floats cut to ease the pipework into the excavated trench.

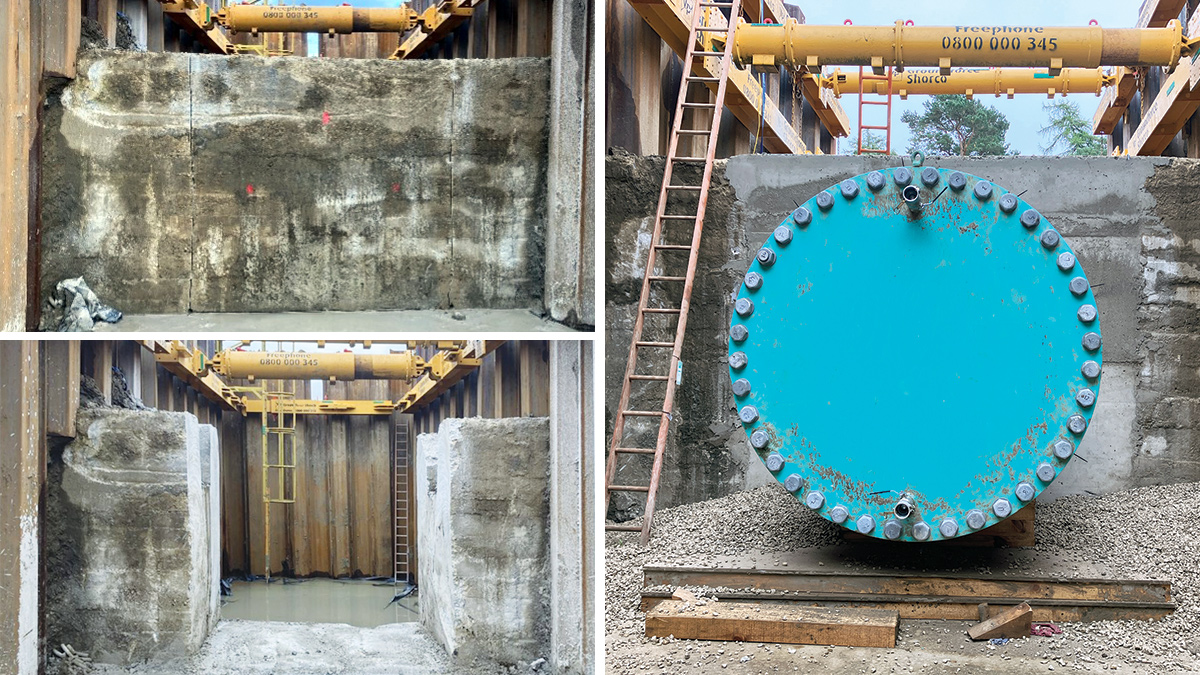

Meanwhile, MMB commenced the construction of the downstream leg of the siphon, connecting onto the length previously installed in 2017 as well as installing the cofferdam. To facilitate the length of siphon through the crest, a section of the concrete core required removal. The use of wire cutting reduced HAV’s to zero and provided a perfect surface for reinstatement; with 82 tonnes of concrete removed.

Once the siphon pipework was installed within the aperture, the core was sealed by dowelling into the existing core and pouring a new fibre-reinforced concrete surround, saving time constructing reinforcement and providing carbon savings.

Hydrotite was applied around the pipe-concrete interface, with imported puddle clay compacted on top to Peak Flood Level.

Concrete core: (top left) before and (bottom left) after wire cutting with 82t of concrete removed, and (right) Reinstated concrete core following installation of 1600mm pipe prior to connection with the upstream leg – Courtesy of Mott MacDonald Bentley

Project status

As of May 2024, the scheme had in excess of 300 ‘Perfect Days’, with zero service strikes or lost time incidents. Multiple work experience students have visited and spent time on site, to witness the scheme and sample construction work life. Significant elements including siphon pipework and priming apparatus have been installed, with final installations and site reinstatement ongoing prior to full commissioning taking place in June 2024. The Gouthwaite Reservoir Project has prioritised being sympathetic to the local environment, bringing a 19th century structure up to 21st century safety standards and ultimately providing safeguards to the downstream community.

Pontoon excavator - Courtesy of Jifmar Group