Witches Oak WTW: Green Recovery – Decarbonising Water Resources (2023)

CeraMac® ceramic membrane - Courtesy of PWNT (part of the Nijhuis Saur Industry Group)

In the summer of 2020, the water industry was set a challenge by its regulators to identify ways to support the country’s green economic recovery from Covid-19. Severn Trent responded with a number of proposed programmes, including Decarbonising Water Resources (DWR), the subject of this paper. The objective of the DWR programme was to provide additional treated water to the Severn Trent water network in a low-carbon, reduced-chemical treatment way. The need for this additional water is based on Severn Trent’s supply demand balance taking into account drought, climate change, the future reduction in groundwater abstraction and the need for more resilient water supplies. In 2020 Severn Trent secured the abstraction license for the River Trent from the decommissioned Rugeley power station. This license was for a peak abstraction of 93 Ml/d and was appended by the Environment Agency to the Severn Trent existing site at Witches Oak.

Background

In the 1990s Severn Trent constructed a pumping station at Witches Oak to abstract water from the River Trent which made use of three gravel beds operating as bankside storage to reduce the turbidity of the water. From Witches Oak the raw water was pumped to Draycott Reservoir which supplies the existing Church Wilne Water Treatment Works (WTW).

The aim was for Church Wilne WTW to treat a blend of water from the River Trent and the River Derwent. However, this arrangement was only partially successful and was found to be expensive to operate due to the high dose of powdered activated carbon required for treatment of River Trent water. Consequently, the Witches Oak abstraction was stood down and Church Wilne WTW was supplied solely with raw water from the River Derwent.

Google Maps image showing the Witches Oak gravel beds

Decarbonising Water Resources Programme

With the development of new and improved treatment technologies since the 1990s, the DWR programme was conceived with the aim of treating raw water from the River Trent. Buying the Rugeley license meant that this water could be abstracted with no net reduction in flow in the River Trent downstream of Witches Oak.

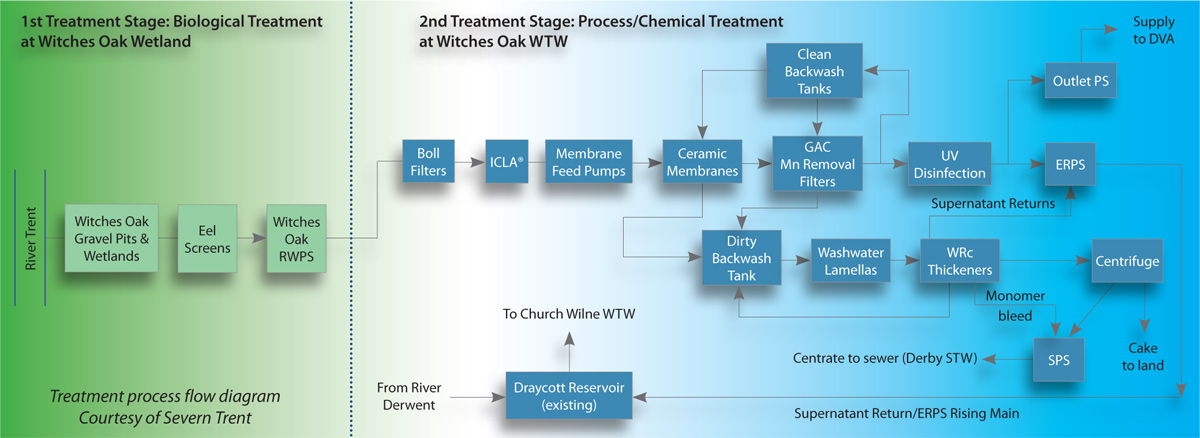

The DWR programme embraces innovative water treatment processes by making use of natural biological treatment (wetlands pre-treatment) prior to more conventional process and chemical treatment.

The water into supply date agreed with OFWAT for the DWR programme is 31 March 2025. The programme has been divided into a number of projects as follows:

- Raw Project: This project covers the refurbishment of Witches Oak Abstraction Pumping Station (PS) and the construction of the wetlands pre-treatment.

- Treated Project: This project is comprised of the design and construction of the new water treatment works (called Witches Oak WTW).

- Pilot Plant Project: This project provides the design criteria for the full-scale processes selected to treat the River Trent water.

- Distribution Project: This project is comprised of the infrastructure required to deploy the treated water from Witches Oak WTW into the Severn Trent grid.

These projects will be the subject of future more detailed papers over the next two years as construction progresses.

Google Maps showing the proposed location of new Witches Oak WTW

Raw Project

The scope of this project is to refurbish the existing river abstraction pumping station to enable raw water to be supplied to the new Witches Oak WTW. The Raw project also includes the first stage of treatment using floating reedbeds as biological treatment to reduce the turbidity and nitrates in the raw water.

Floating reedbeds were chosen rather than a planted wetland for several reasons:

- Witches Oak floods regularly during the winter and consequently a planted wetland would largely be submerged during these periods losing any process benefit the reeds provide.

- Additionally, the maintenance of the floating wetlands is much simpler, with the reeds being planted on floating pontoons, they can be towed to the gravel bed bank to enable the reeds to be replaced or maintained.

The first three floating reedbeds where installed in the Autumn of 2022, an additional seven reedbeds were installed in April/May 2023 with the remaining twenty to be installed by the end of the Summer 2023. The reedbeds are being installed on an accelerated timeline to allow the reeds to mature as much as possible before the new Witches Oak WTW becomes operational.

Floating reedbed – Courtesy of Severn Trent & Biomatrix

Treated Project

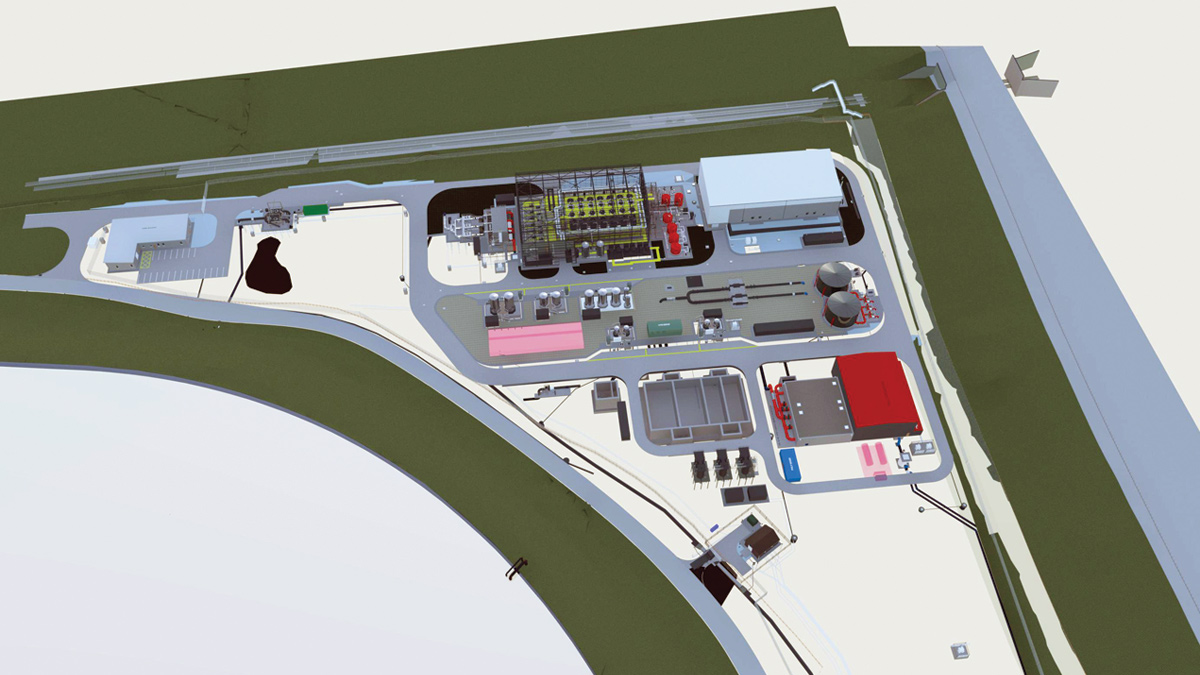

Witches Oak WTW is located on Severn Trent owned operational land to the north of the existing Church Wilne WTW. The new water treatment works is bounded by the M1 to the East and a railway line to the North. Planning permission for the new water treatment works was secured in March 2023. The processes selected for the new water treatment are:

- Auto backwashing screening filters (Bollfilters®).

- Inline coagulation (ILCA®).

- Ceramic membranes (CeraMac®).

- Granular activated carbon (GAC) filters.

- Twin ultraviolet (UV) reactors and chlorine contact main for disinfection.

- Washwater recovery with lamellas and sludge handling system.

- Emergency return pumping station (ERPS).

The contract for the new Witches Oak WTW was executed with the Severn Trent framework contactor MWH Treatment in January 2023. Prior to this MWH Treatment had been working on the development of the design with Severn Trent under an Early Contractor Involvement (ECI) agreement. Key activities under the ECI included removal of spoil from the site in preparation for construction, development of the target price whilst looking at potential value engineering opportunities and procuring long lead items.

Treatment process flow diagram – Courtesy of Severn Trent & MWH Treatment

The subcontract for the ILCA® and CeraMac®, both proprietary equipment, was awarded to PWNT (part of the Nijhuis Saur Industry Group) and both technologies are being piloted, under the Pilot Plant Project.

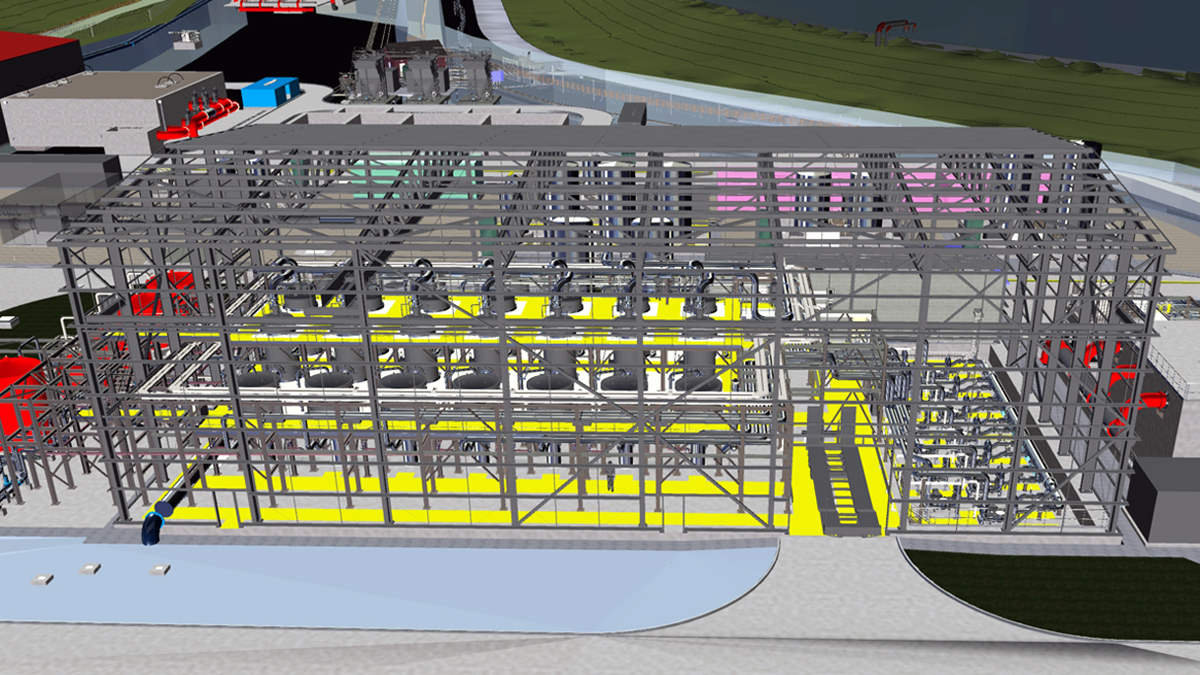

Using MWH Treatment’s expertise, the design of the new WTW has been developed in 3D with 4D being used to look at programme sequencing and overlapping site activities due to the short construction and commissioning duration of 24 months. Off-site manufacture is being deployed as much as possible.

At the time of writing (June 2023) on site activities have so far focused on groundworks relating to the two largest structures on site; the ceramic membrane building and the GAC. MWH Treatment will next start construction of the treated water high lift pumping station and dirty backwash tanks. Earthworks have been completed with the removal of 72,000m3 of surplus material which has been used as backfill at Shardlow quarry in Swarkstone.

Local companies JC Balls & Sons and Naylor Plant Hire & Excavations Ltd have performed very well and taken care to minimise the impact of 100 vehicle movements per day whilst keeping the roads of the surrounding area clean. Piling and the civil construction of the GAC structure is advancing ahead of schedule due to the high-quality resources deployed by STAM Construction Ltd.

Witches Oak WTW 3D site layout – Courtesy of Severn Trent & MWH Treatment

River Trent water quality challenges

The key River Trent water quality challenges are:

Organics: Organic matter left in final water after treatment slowly reacts with residual chlorine which is dosed for network distribution and can form trihalomethanes (THMs). Consequently, the PCV (prescribed concentration or value (PCV) as defined in the Water Supply (Water Quality) Regs) for THMs is measured at the customers taps. Although there is no numeric PCV for total organic carbon (TOC) in the UK, Severn Trent generally try to achieve less than 2mg/l in the final water in order to limit THM formation. Long distribution times to customers taps and warmer water increase the THM formation potential.

The River Trent has a high concentration of organics (>10mg/l) and the fractionation between hydrophilic (those that ‘like water’ and are difficult to remove) and hydrophobic (those that ‘dislike water’ and are easier to remove) is such that the ILCA® coagulation process will not be sufficient to remove enough of the organics on its own.

Polyfluoroalkyl substances (PFAS): Severn Trent have identified two PFAS compounds that are in Tier 3 category based on the DWI guidance issued to the Water Companies in July 2022. Severn Trent have already carried out an assessment of the various treatment technologies currently available to treat PFAS and although in their infancy for this emerging risk, Severn Trent are piloting various activated carbon solutions to enable PFAS to be removed effectively from the raw water. Severn Trent are keen to select a technology that removes the PFAS from the environment and activated carbon is currently the best option to achieve this.

It is expected that an activated carbon solution will be implemented to deal with both the high concentrations of TOC and PFAS in the raw water as a single treatment stage in AMP8. Ion exchange and reverse osmosis were considered however there are considerable problems to overcome in dealing with the waste product from these processes which would contain concentrated PFAS.

Nitrates: Based on historic data the levels of nitrate in the River Trent have exceeded the PCV of 50 mg/l occasionally and breached Severn Trent’s internal standard on a regular basis.

The floating wetlands, which are being constructed as part of the Raw Water Project, are expected to reduce nitrates below the Severn Trent internal standard.

Pesticides: There are numerous pesticides/herbicides in the River Trent and the installation of the GAC stage of treatment with an empty bed contact time (EBCT) of 20 minutes is expected to be sufficient to reduce the pesticides below PCV.

Render of GAC plant – Courtesy of Severn Trent & MWH Treatment

Pilot Plant Project

Due to the water quality challenges in treating the River Trent and the new technologies being implemented Severn Trent decided to pilot the new processes.

The pilot plant was constructed and commissioned during 2022 and is located at Church Wilne WTW. The pilot plant takes raw water directly from the River Trent as taking a small pilot plant abstraction from the Witches Oak gravel beds would not provide a representative sample of raw water quality due to the prolonged settlement time. The pilot plant includes GAC filter columns as well as the ILCA® and CeraMac® to enable Severn Trent to investigate different types of carbon media and their performance at pesticides, organics and PFAS removal.

In addition, ActiCarb® technology supplied by Veolia Water Technologies is due to be added to the pilot plant in 2024 to enable testing of this process in relation to organics and PFAS removal.

Distribution Project

The new Witches Oak WTW will be connected into Severn Trent’s grid to enable the additional potable water to be distributed where it is most needed. Twin 700mm ductile iron pipes from Witches Oak WTW will be laid through the existing Church Wilne WTW site and connect into the Derwent Valley Aqueduct. The detailed design for these pipelines was completed by Severn Trent’s design partner Mott MacDonald in June 2023.

Severn Trent plan to be in contract for these pipelines with a build only contractor in July 2023.

Witches Oak WTW: Supply chain – key participants

- WTW designer/main contractor: MWH Treatment

- Witches Oak build contractor: MMB

- Distribution Project build contractor: Barhale

- Wetlands designer/build contractor: Biomatrix

- Distribution Project designer: Mott MacDonald

- Biodiversity improvements designers: Arup

- PFAS treatment pilot plants specialist process engineering designers: WISP Global Ltd

- ILCA® & CeraMac® technologies: PWNT (part of the Nijhuis Saur Industry Group)

- Earthworks: JC Balls & Sons

- Earthworks: Naylor Plant Hire & Excavations Ltd

- Witches Oak FRC sub-contractor: STAM Construction Ltd

- Temporary works/shoring: National Trench Safety UK

- Backwashing screening filters: Bollfilter UK Ltd

Witches Oak WTW construction progress (Spring 2023) – Courtesy of Severn Trent & MWH Treatment

Conclusion

In order to deliver such a technically complex project in line with a challenging programme, all parties agreed that a collaborative approach was essential. The Project Team have fully embraced this culture and are working collectively to mitigate the risks and unlock opportunities. The MWH Treatment design team has integrated with Severn Trent’s Engineering and Operations staff, together with the CeraMac® technology providers PWNT to optimise the design.

Severn Trent plan to start commissioning of the raw, treated and distribution projects together in early January 2025 with 65Ml/d available for supply to customers by 31 March 2025. Further papers will be provided in Water Projects and WaterProjectsOnline next year once all three projects are in construction.

Further updates with Water Projects are also planned on the PFA/organics pilot plant trials and the process selected to remove these from the raw water. Severn Trent intend to construct a PFAS and Organics removal process at Witches Oak WTW by mid AMP8.