Haxey Graizelound STW (2025)

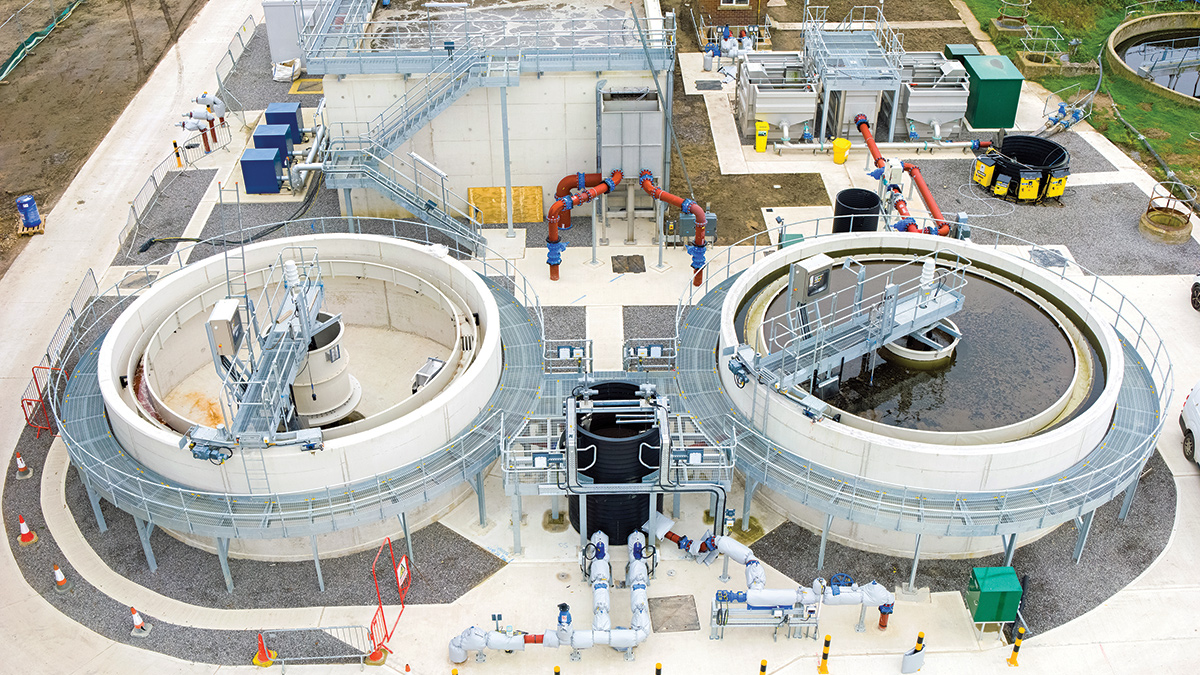

New FSTs and FST distribution chamber and ASPs in the background - Courtesy of MMB

Located in North Lincolnshire, between Scunthorpe and Doncaster, Haxey-Graizelound STW is an existing medium-sized biofilter works serving the town of Haxey and Westwoodside Village. It has a permitted flow to full treatment (FFT) of 27.7 l/s and serves a population equivalent of 5,169 (rising to 5,464 in 2033). To achieve the new Total Phosphorus (TP) and ammonia consents that came into force in December 2024, a new activated sludge plant with enhanced biological phosphorus removal was constructed on the existing site, which had to remain fully operational during construction and commissioning.

Existing works

The existing works comprised an inlet works (single screen and grit vortex), a primary settlement tank, four biofilters, one final settlement tank, final effluent monitoring, a storm tank and returns, and two sludge holding tanks.

The driver for the new works is a tightening in the Total Phosphorus (TP) and ammonia consent that came into force December 2024.

| Existing consent | New consent | ||

| BOD | 25 | BOD | 25 |

| SS | 45 | SS | 45 |

| NH3 | 15 | NH3 | 3 |

| TP | – | TP | 0.2 |

| FE | – | FE | 4 |

| AL | – | AL | 8 |

| FFT | 27.7 l/s | FFT | 27.7 l/s |

The new treatment works

The existing works is a fully pumped works with two catchment pumping stations (from Akeferry and Westwoodside) pumping to the inlet. The process of the new works starts off with primary treatment, where two screens from Huber Technology and a grit vortex from SPIRAC Ltd capture and remove inorganic materials (e.g. wet wipes and rocks) to be taken to landfill. After preliminary treatment, the flow enters a balancing tank to maintain flow to full treatment (FFT) during higher flows, preventing premature storm spills.

The secondary treatment consists of a pocket UCT ASP (University of Cape Town activated sludge process), 37.5m (length) x 11m (width) x 6m (height), two 8.95m internal diameter final settlement tanks (286.6m3 total volume) and a RAS return pump station, with integrated SAS thickening facility that leads to the sludge storage tank.

Construction progress (March 2024) – Courtesy of MMB

The ASP consists of two anaerobic pockets (total volume 115m3) to allow the site to utilise biological phosphorus removal, where the phosphorus removing organisms have a competitive advantage, due to there being no free oxygen for other organisms to use.

These pockets then flow into two anoxic zones (total volume 115m3) in which free oxygen is available for denitrification purposes. The flow then enters three aerated pockets (total volume 1,513m3) with tapered airflow, reducing in the percentage of supplied oxygen in each subsequent pocket – this is to reduce the amount of dissolved oxygen and nitrates recycled back to the anoxic zone in the form of RAS.

As this is a UCT configurated ASP, there is also a fixed speed denitrified mixed liquor pump, recycling anoxic effluent back to the anaerobic feed, this is to maintain anaerobic conditions within the anaerobic pockets.

Ferric sulphate is dosed into the final settlement tank distribution chamber (to act as a top-up dose in case EBPR is not consistently meeting the 1 mg/l target of total phosphorus off the ASP). The flow then splits equally to the two final settlement tanks which have half-bridge scrapers. The sludge is drawn off by the return activated sludge (RAS) return pump station that feeds into the start of the ASP to maintain the cyclical process.

New ASP taken from top of new inlet works – Courtesy of MMB

A secondary dose of ferric is supplied to the Mecana pile cloth filter (pre-TSR dose) from Eliquo Hydrok Ltd. This allows precipitation of soluble phosphorus, to further polish both the suspended solids and total phosphorus to meet the low 0.2 mg/l consent. The flow is sampled and monitored at the final effluent kiosk, before discharging to the outfall.

The surplus activated sludge (SAS) is directed towards sludge handling facilities which include a Huber S-DISC sludge thickener and polymer dosing equipment. The thickened sludge will then be held in a new sludge holding tank to be taken from site for use at other Severn Trent treatment works.

New scope of works

The full scope of the works is detailed below:

- New raised inlet works comprising two screens and wash compactor with grit vortex and screw classifier.

- New UCT activated sludge plant with EBPR, consisting of two anaerobic zones, two anoxic zones and three tapered aeration pockets.

- Two new final settlement tanks.

- New RAS SAS pump station.

- New tertiary solids removal plant (Mecana pile cloth filters from Eliquo Hydrok Ltd).

- New chemical dosing unit.

- New sludge holding tank.

- New SAS thickening equipment.

- New main MCC and SAS thickener MCC.

- New laboratory.

- New pump stations and drainage.

- New road layout.

New TSR and FE – Courtesy of MMB

Haxey Graizelound STW: Supply chain – key participants

- Client: Severn Trent

- Principal designer & contractor: Mott MacDonald Bentley

- Electrical subcontractor: Main Electrical Ltd

- Mechanical subcontractor: STAL (UK) Ltd

- Inlet screens & compactor: Huber Technology

- Grit removal plant: SPIRAC Ltd

- Stainless steel tanks: Fluid Sealing & Engineering (FSE)

- Aeration diffusers for ASP: Suprafilt Ltd

- FST scraper bridges: Jacopa Ltd

- Weholite prefabricated chambers: SDS Limited

- FRC: Overhall Contractors Ltd

- Mecana tertiary solids removal: Eliquo Hydrok Ltd

- Glass-coated steel tanks: Goodwin Tanks Ltd

- MCCs: CEMA Ltd

- Kiosks: Morgan Marine

- Huber S-DISC sludge thickener: Huber Technology

- Ferric dosing: Colloide

- Mixers & submersible pumps: Xylem Water Solutions

- RAS pumps: Sulzer Pumps Wastewater Ltd

- SAS pumps: NOV Process & Flow Technologies UK Ltd

- Plug and Play VT2 & VT3 Booster Sets: Dutypoint Ltd

- DI pipe: Saint Gobain PAM UK

- Valves: AVK UK Ltd

- Penstocks: Waterfront Fluid Controls

- Lifting equipment: T Allen Engineering Services Ltd

- Access steelwork: Mectec Engineering

New sludge holding tank – Courtesy of MMB

Innovations, cost savings & carbon reduction

Following a cost benefit analysis carried out between Severn Trent and MMB in 2022, the preferred solution was to construct a crude activated sludge plant (ASP) with enhanced biological phosphorus removal (EBPR).

There were several challenges that the MMB design team and site team were able to overcome by working closely together.

Sub-artesian water pressure

During ground investigation it was identified that the site had high groundwater level with sub-artesian water pressure. Since the process is gravitated after the inlet works, the depths of the structures in the outline design would have been significantly impacted by sub-artesian water, requiring significant temporary works including groundwater abstraction. The design team was able to overcome this issue by interrogating the hydraulic calculations and highlighting the opportunity with Severn Trent to raise the inlet works and the ASP structure up, with the bases of the two FSTs rising to ground level.

Because of this, the team were able to avoid the sub-artesian water pressure and reduce the groundwater impact during excavation and construction, significantly reducing construction health and safety risks, and realising environmental and commercial benefits.

New chemical dosing area – Courtesy of MMB

Simplifying the TSR design

The original TSR design had a large bunded area that required a deep excavation and the use of more materials. Early on, the design team was able to discuss options with the supplier and other sites that had installed the same technology.

The option to part-bury the tanks enabled the removal of the large, below-ground bunded design, simplifying it to a single rectangular slab that the tanks would sit on and be backfilled around. This did not affect the hydraulics or the process and reduced the total excavation required and concrete usage which in turn, reduced the embodied carbon of the solution.

Inlet works location

A review of the construction programme and site layout highlighted an opportunity to construct the inlet works earlier whilst keeping access to the ASP and MCC area. The outline design had the new inlet works to the north of the existing inlet works. This would have prevented the MCC from being constructed as the crane would be located on top of it to service the original position.

However, during a design sprint with Severn Trent, the new inlet works was moved to the south of the existing inlet works. Whilst this meant it was located over an area with several services – since the level had been raised – the slab now sat above all the services in the area and would not clash. The site team was able to locate and prove the existing services, then excavate and construct the new slab and pipework.

New inlet works screens and grit removal plant – Courtesy of MMB

Site-drainage pumping station

A review by the MMB design team of the requirements for the new site-drainage pumping station found that the existing pumping station had sufficient space, volume and was in suitable condition to take the new flows and pumps that were required for the new works. This saved programme, time, cost and risk in having to construct a new site returns pumping station in an area heavily congested with live services including the main incomer to site, as well as remove any interface with the sub-artesian water.

Design efficiencies

There were several design efficiencies that were realised during the detail design phase including:

- Changing the bypass channel sections on the raised inlet works into a piped bypass, which improved constructability and programme.

- Changing the ASP blister and FST distribution tanks from large concrete structures into prefabricated stainless-steel tanks resulted in carbon savings, programme savings and ease of constructability.

- Three prefabricated Weholite above-ground chambers from SDS Limited helped save on programme and concrete usage.

BIM360

Several benefits were gained during the project with the close communication between the site and design teams through regular site visits, weekly meetings and the use of Issues on BIM360, which helped to streamline the production of drawings.

Reviews by the relevant design disciplines and the site team could be tracked, and buildability checks could be raised in a timely manner. This also helped to improve design decisions having the early site involvement and helped to reduce redesign. The great construction and design collaboration helped to identify opportunities to enable services to either have a reduced dig depth or be constructed out of the ground, further reducing the ground water interface. One example being the FST outlet pipework being kept above ground to the collection chamber, which removed all excavation requirements.

New S-DISC SAS thickening equipment – Courtesy of MMB

ASP maturation

Significant programme gain came from challenging the ASP maturation period. The initial programme had 28-weeks for maturation, however, regular meetings between process engineers from both MMB and Severn Trent were held. This led to the development of a joint commissioning plan whereby hold points and process reviews could be used to trigger the next stage of the commissioning works.

Instead of waiting for the Severn Trent standard commissioning duration, if the target was achieved sooner, a joint review would be carried out and the next stage could start. This led to the maturation period of the ASP to be reduced to 12-weeks.

Water voles

Water voles impacted works on the installation of a new culvert for crossing the drainage ditch to which the site discharged.

MMB ecologists were able to carry out a survey of the occupational drainage ditch and highlight the areas where water vole habitats were located. A review carried out by both the design team and site team, found that by moving the culvert approximately 20m further north, it would still provide a suitable crossing point to site, whilst having no impact on the water voles or habitats.

Concrete sensors

An innovation that was used at Haxey STW during the construction of the ASP were converge concrete sensors. When constructing the concrete activated sludge plant, the team identified an opportunity to trial sensors to measure the concrete strength. The structure consisted of 6m tall in situ concrete walls; the perfect set up to trial the sensors.

(left) Concrete sensor being cast into the wall and (right) analysis of data collected – Courtesy of MMB

Initially the team were using a PERI shutter system and part of the temporary works states that the shutters cannot be struck until the concrete has reached 5N/mm2 compressive cube strength. With the ASP on the critical path of the programme, it was imperative that the walls were poured as efficiently as possible, striking the shutters as soon as possible, then moving onto the next pour.

The concrete sensors were cast into the walls and proved extremely effective as they were able to read the temperature of the concrete, convert it to compressive strength and notify the team when the shutters could be stripped. This resulted in an efficient process between each pour, streamlining the pour schedule and reducing the reliance on concrete cubes.

Using the sensors, the team were able to save one day per section of wall poured, removing 11 days from the programme. Both time and costs were reduced due to not having to prepare 45 cubes for early strength testing, saving over £700 in engineer time and cube crushing.

The key benefits of the sensors are:

- Gain on programme.

- Quick turnaround.

- Lower carbon footprint.

- Instant strength monitoring.

- Quality assurance.

Completed works (January 2025) – Courtesy of MMB

Conclusion/summary

The main construction phase was completed by December 2024 with the commissioning phase subsequently starting after.

The project has been successful by the close communication between the client, site team, design team and operations. By having regular meetings throughout the week enabled both sides to raise and questions/concerns, ideas to be discussed and decisions made in a timely manner.

With flows switched to the new works, the existing works is to be decommissioned and abandoned.

New FSTs and FST distribution chamber taken from on top of new ASP - Courtesy of MMB