Holdenhurst WRC (2025)

IFAS steelwork installation - Courtesy of Trant Engineering

Holdenhurst Water Recycling Centre (WRC) is a Wessex Water facility situated near Bournemouth, Dorset. It is a large activated sludge works, which currently serves a total population of approximately 180,000 which significantly increases during the summer months. The WRC was identified by the Environment Agency in the Water Industry National Environment Programme (WINEP) as requiring process improvements, including the reduction of phosphorus levels in the treated wastewater prior to release to the River Stour, which then flows into Christchurch Harbour, and the provision of additional storm storage capacity.

Regulatory obligations

The regulatory obligations include a phosphorus (Total P) permit of 1 mg/l during AMP7 and beyond. However, it was decided that additional investment would be made to enable the AMP7 works to meet the needs of the improved AMP8 0.8mg/l Total P stretch target. Key parameters for the treated flows are as follows.

| Flow to full treatment | Total phosphorus | Iron: 95% ile (mg/l) | Aluminium maximum |

| 1424 l/s | 0.8 mg/l | 4 mg/l | 3.6 mg/l |

The obligations also include the requirement to provide an additional 9,000m3 of additional storm storage (increasing the total capacity to 29,800m3). Other requirements include Event Duration Monitoring (EDM).

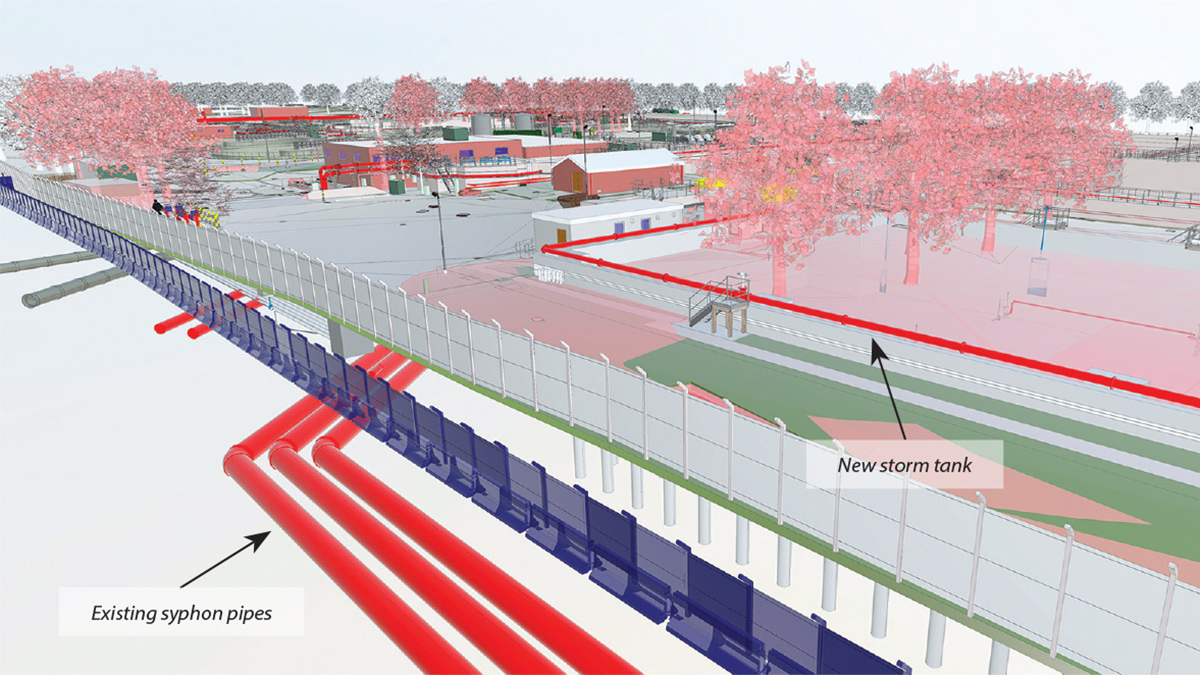

3D model showing the proximity of the existing assets – Courtesy of YTL

Proposed solution

Phosphorus removal: Separate chemical dosing installations are to be provided for the two existing treatment streams within the site to achieve the phosphorus removal. The chemical dosing will utilise polyaluminimum chloride (PAC), which was selected to avoid the anticipated adverse impacts on the site’s ultraviolet (UV) treatment plant which would arise from using ferric compounds.

Stormwater storage: Additional capacity is to be achieved by the construction of a new reinforced concrete below-ground, gravity fed tank (65m long x 35m wide x 6m deep) constructed on 154 (No.) 750mm diameter continuous flight auger (CFA) concrete piles. Other main elements of the project include:

- Storm return pump station integral to the main tank structure and connection of all return storm flows to the existing works inlet.

- Pump mixers.

- Interconnecting pipework between the existing storm tanks and the new tank.

- Reinforced concrete launder channel.

- Storm overflow.

- Modification to existing storm tank weirs and addition of penstocks to control flows.

- Extension of washdown pipework.

- New MCC and automation and control systems.

- EDM instrumentation.

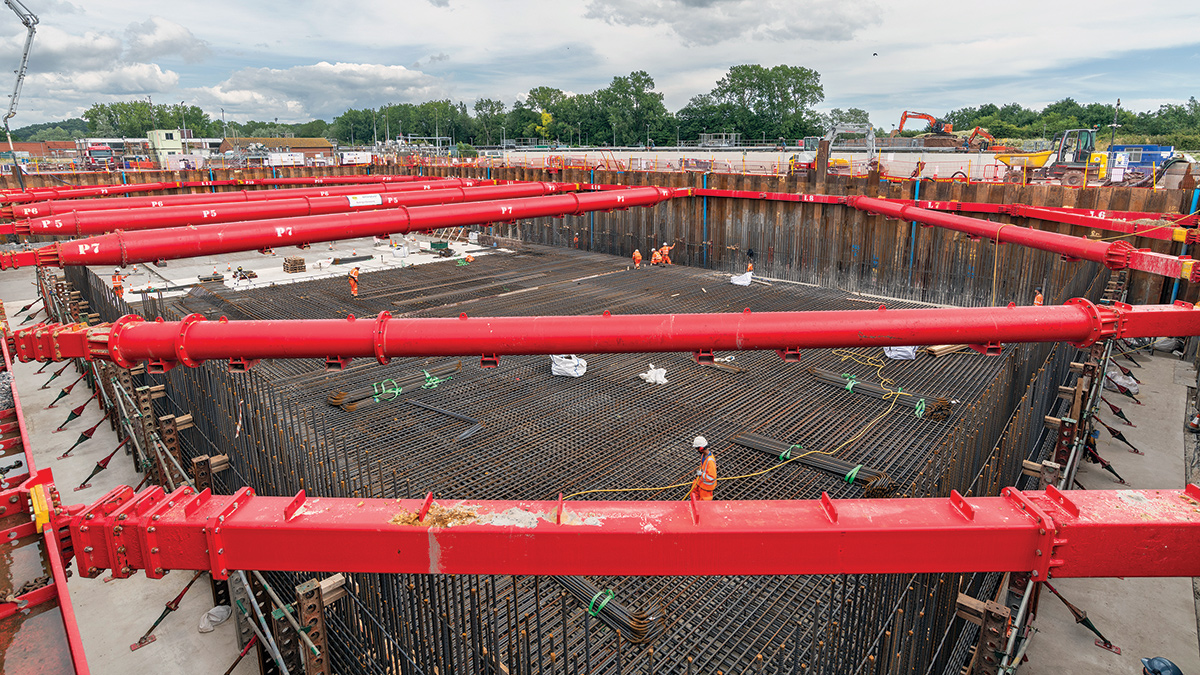

(left) Storm Tank 15: CFA piling installation and (right) Storm Tank 15 construction progress (July 2024) – Courtesy of YTL and Envolve Infrastructure

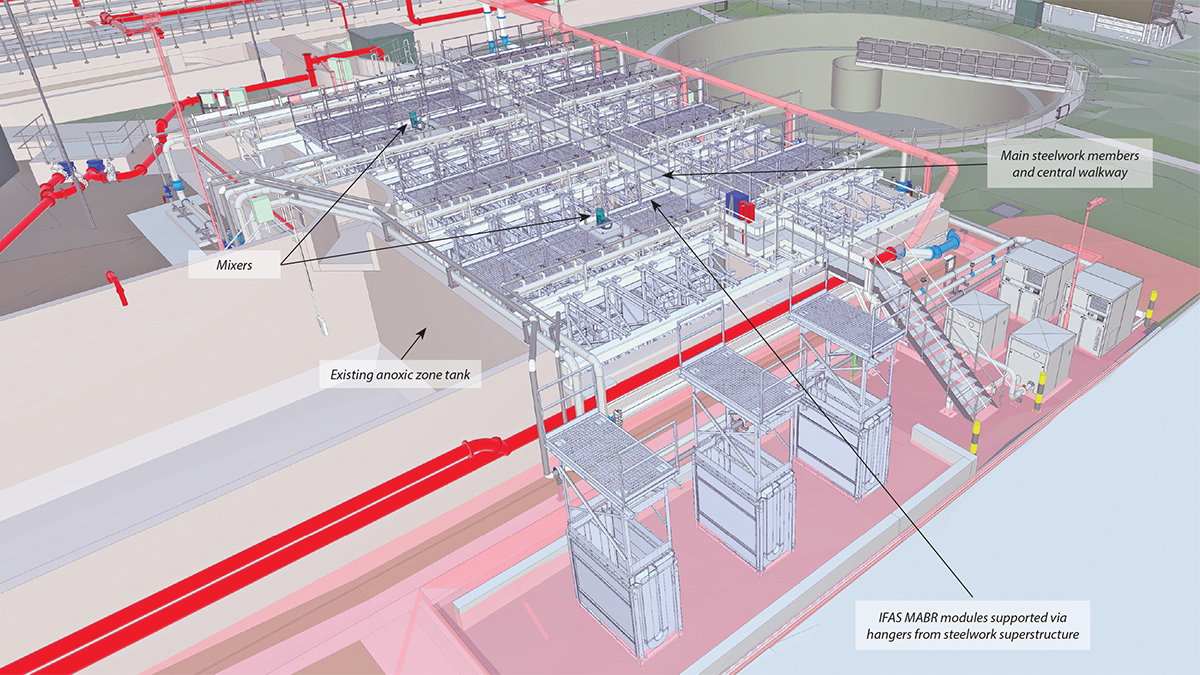

Suspended solids resilience: In addition to the works above and to assist with suspended solids resilience, further works to install 50 (No.) Integrated Fixed-Film Activated Sludge (IFAS) modules to ensure that suspended solids performance on the existing treatment Stream 1 is sufficient. This will support compliance with the new phosphorus permit standards. The system will enable the relevant aeration lanes to operate at a mixed liquor suspended solids (MLSS) concentration of 2,400 mg/l.

The solution was to be designed for the 2040 horizon, however installation in AMP7/AMP8 will be for the 2030 horizon, but with facility to extend subject to performance and any revised horizon. It will be the largest installation of this type in the country.

Works to facilitate this installation include:

- Retrofit of the existing anoxic and contact zone selector tanks to include a new IFAS MABR module support superstructure.

- Two scour and two process blowers.

- Scour and process air pipes including valves, ancillaries and pipe supports.

- Associated MCC, control system, kiosk, cabling and instrumentation.

- Permanent crane slab to enable installation, removal and maintenance of the modules.

Additional sludge storage: Surplus sludge is pumped from Holdenhurst WRC to Berry Hill Sludge Treatment Centre (STC). As a consequence of dosing with PAC, increased sludge production is anticipated, and therefore 740m3 of additional sludge reception and holding capacity was constructed at the Berry Hill STC. The main elements of works for this include:

- Refurbishment of currently disused tank to provide additional raw sludge reception, including new stainless-steel panels, GRP roof, high-level access platform, mixer system and pipework.

- Refurbishment of existing SAS/raw mixing tank including new stainless-steel panels, GRP roof, high-level access platform, mixer system and pipework.

- New 740m3 stainless steel SAS reception tank, GRP roof, new piled foundation and base slab, mixer system and pipework.

- Two raw sludge transfer pumps, two SAS transfer pumps and replacement of existing SAS GBT feed pumps.

- Modifications to rising mains.

- Associated MCCs, control system, kiosk, cabling and instrumentation.

Berry Hill STC sludge thickening tank – Courtesy of Galliford Try

Project delivery

Project Delivery was managed by YTL Construction (Wessex Water) under its external workstream comprising:

- Design consultants: Mott MacDonald

- Principal & civils contractor: Envolve Infrastructure

- MEICA contractor: Trant Engineering

- Automation & Commissioning: YTL Construction

- Berry Hill sludge capacity civils & MEICA: Galliford Try

The collaborative approach by all delivery partners and industry specialists enabled this £30m capital investment programme of works to be effectively developed from optioneering, through detailed design, construction and commissioning to achieve successful delivery of this complex and challenging project in little over 24 months.

Holdenhurst WRC: Supply chain – key participants

- CFD Modelling: Invent AG

- Dewatering design & CAT3 check: Richter Associates

- Dewatering subcontractor: Dewatering Services Ltd

- Piling subcontractor: Balfour Beatty Ground Engineering

- Cofferdam & temporary works designer: JIG Consulting Engineers

- Temporary works/shoring: MGF Ltd

- Temporary works/piling: SPI Piling

- Coring & demolition: Southern Counties Drilling Solutions

- Reinforced concrete subcontractor: Carney Construction

- Reinforcement: ROM Reinforcements

- Specialist sub-designer/IFAS membranes: DuPont Water Solutions | OxyMem Ltd

- Steelwork subcontractor: Woodhams Group

- MCC, panel & kiosk: GPS Group

- Valves: AVK UK Ltd

- Actuated penstocks: Glenfield Invicta

- Storm return pumps: Xylem Water Solutions

- Storm mixer pumps: KSB Pumps

- Lifting gantry: Able Lifting

- Chemical storage tanks: Forbes Group

- Pipework: Saint Gobain PAM UK

- Pipework: Frazer Civils Infrastructure

- Concrete: Avon Material Supplies Ltd

Berry Hill STC: Supply chain – key participants

- Civils sub-contractor: Bartlett Contractors Ltd

- Piling design & installation: Suttle Projects Ltd

- Electrical installation: Spectrum Electrical Group

- Stainless steel tanks: Hayes GFS Ltd

- Tank mixer pump supplier: Hidrostal

- Pumps: Nov Process & Flow Technologies UK Ltd

- MCC, panel & kiosk: GPS Group

- Stainless steel pipe fabrications: ABC Stainless Ltd

- Access platform fabrications: Atom Fabs Ltd

- Trace heating & lagging: Jade Insulation

Storm Tank 15 (July 2024) – Courtesy of Envolve Infrastructure

Design & ECI

Through early contractor involvement (ECI) during the design phase, Envolve Infrastructure and Trant Engineering were able to use their specialist sector knowledge to guide the project team through key constructability decisions.

Assessments were made with regards to safety, quality, time and cost aligning with all partners underlying business ethos.

At the outset, Envolve Infrastructure worked closely with all stakeholders to develop a construction methodology for the storm tank. Numerous options were considered for providing the circa 9,000m3 of additional storage including caisson shafts, secant piling, precast concrete tanks and variables of an in situ RC tank, and a detailed comparison report was undertaken for all methods. The concluding findings were that a 65m x 35m x 6m rectangular in situ RC tank would provide the optimum solution due to the challenging ground conditions, time constraints, ongoing operability and whole-life cost.

In addition, further crucial decisions were considered in relation to the storm return pumping station; initially options were presented for a standalone construction, however Envolve Infrastructure worked with the stakeholders to develop a solution of an integrated pump station which generated both programme and costs efficiencies.

Storm Tank 15: Frame removal – Courtesy of YTL

Challenges & mitigation

Stormwater tank construction – existing ground conditions: Ground conditions at Holdenhurst WRC are inherently poor, consisting of a high-water table and the presence of running sands.

The large-scale cofferdam required for the stormwater holding tanks posed significant geotechnical challenges and demanded a specialised design to ensure safe and effective excavation.

Envolve Infrastructure undertook additional ground investigation including a reduced size trial cofferdam. The ECI provided by Envolve throughout the design development stages of the project identified the significant advantage of using a cantilevered sheet pile arrangement rather than a traditional top frame support of the cofferdam.

The proposal allowed for the cofferdam sheet piles to be propped at tank base slab level by filling the 2.5m gap between the sheet piles and base slab with mass concrete, therefore allowing the removal of the top frame, and construction of the tank walls in a single lift rather than two, providing an enhanced solution in terms of safety, quality, time and cost.

Storm Tank 15 (March 2025) – Courtesy of YTL

Groundwater: Due to a high-water table and high permeability of the ground, Richter Associates were consulted to advise on dewatering requirements to enable the construction of the storm tank.

Pump tests were undertaken to inform the dewatering design and for inclusion in the EA Abstraction License application. The final design catered for an abstraction rate of 60-100 l/s, targeting a drawdown level of approximately 8m below ground level. It comprised of 20 wells around the internal perimeter of the cofferdam, together with three internal passive wells to depressurize the Poole Formation.

Groundwater was delivered to a booster pump station by 20 down hole pumps, which then pumped the groundwater to the discharge location. The pumping arrangement had to be robust, with duty/standby pumps as well as back-up power supplies.

Strict EA permit conditions required the discharged water to meet set levels for turbidity, pH and flow rate. The dewatering discharge was via the storm overflow pipework to the River Stour and, while the trials indicated that the discharge should not present a pollution issue, real-time water quality and CCTV monitoring linked to remote alarms and automatic shutdown was provided at the point of discharge to the storm overflow pipework to mitigate the risk of pollution events occurring.

The dewatering system was in place for 9 months with 20 pumps discharging 100 l/s, 24 hours/day and worked flawlessly over the duration of construction, providing ideal conditions for the construction of the new stormwater storage tank.

Storm Tank 13/14 overflow & connections – Courtesy of Envolve Infrastructure

Existing assets: Adjacent to the new stormwater storage tank are three 42” spun iron feed syphon pipes, located approximately 3m away from the main cofferdam at an invert level of 3.5m below ground level. These are critical assets for Wessex Water and any compromise could lead to loss of incoming flows and a major pollution event.

A detailed asset protection plan was drawn up and maintained throughout construction, covering installation and removal of the cofferdam sheet piles, CFA piling works, plant/construction loadings, deflection of the cofferdam during excavation and settlement due to dewatering activities.

The pipes were assessed by CCTV and non-destructive testing to determine their condition, and industry specialists employed to establish permissible movement and changes in stress/strain.

The pipes were monitored throughout construction using the following techniques:

| Position/movement | Stress/strain gauges | Down hole extensometers | |

| Vibration | Down hole inclinometers | Groundwater level | |

Throughout the excavation process, a series of monitoring methods were deployed including inclinometers and survey monitoring to measure movement of the cofferdam due to dewatering and the cofferdam construction sequence.

Alarm levels were set at approximately 70% of the assessed maximum, and with any exceedance causing construction to pause and assess impact on the syphons.

Due to the rigorous monitoring plan and tight control during construction, the stormwater storage tank was completed without incident and no exceedances recorded.

IFAS MABR module steelwork superstructure: To suspend the IFAS MABR modules within the existing anoxic and contact zone selector tanks, YTL Construction commissioned Mott MacDonald to develop a steel superstructure. This design was required to take into account of and manage the complex interactions between the existing tank structure, capacity, the module loading and placement, ancillary elements and the superstructure itself.

IFAS steelwork 3D model – Courtesy of YTL

Significant consideration was given to the module and walkway placement and layout. This limits potential damage to the modules during installation and removal for maintenance by ensuring sufficient clearances and ensure safe access for operatives to undertake maintenance.

This was undertaken collaboratively with input from the module designers (OxyMem Ltd) and contractor (Trant Engineering), and an iterative design approach was utilised where required between parties.

Interface with existing assets: There have been several challenges associated with the interface with live operational assets including:

- Adjustment of existing storm tank weirs whilst tanks remain live in case of storm event.

- Construction of IFAS MABR steel superstructure within the existing anoxic and contact zone selector tanks requiring temporary over-pumping whilst the treatment stream remains live.

Planning and management of these activities have required liaison between designers, contractors and Client Operations, and also consideration of timing in relation to weather patterns, to ensure the works were completed safely with no impact on the treatment process.

IFAS steelwork installation – Courtesy of Trant Engineering

Efficiencies & sustainability

A collaborative approach was adopted throughout the design stages to improve buildability, involving YTL Construction, the design consultants and technical specialists together with early contractor engagement.

YTL Construction’s off-site build (OSB) in-house team provided the design, manufacture and supply of pre-assembled standardised equipment. Benefits of this approach are numerous and include improved efficiency and consistency, shorter construction programmes and improved health and safety for workers. The approach can also result in reduced carbon expenditure due to efficiency savings, reduced vehicle movements and reduced site construction time. For this project, the team provided equipment for both of the existing treatment streams such as chemical dosing kiosks, point of application boxes, emergency showers and lighting columns. These were installed on site along with heated chemical storage tanks with working capacity of 65m3 and 40m3, protection bunds and supporting services to provide the new completed chemical dosing facilities.

The image below shows an example of the new facilities as shown in the BIM 3D model developed for the project. This utilised items from a ‘Standard Products Library’ developed by the OSB team, reducing modelling time and improving model standardisation.

3D model of chemical dosing arrangement (courtesy of YTL Construction) and the as-built chemical dosing (Stream 2) delivery & storage bund – Courtesy of Envolve Infrastructure

The innovative IFAS MABR technology from OxyMem Ltd is also associated with significant efficiencies for the wastewater treatment process. These include energy savings resulting from smaller blowers and preventing wastage of unused oxygen, reduced sludge production due to a less turbulent fluid flow and a reduced footprint due to the ability to suspend the modules into existing tanks.

Environmental/carbon reduction

The importance of reducing the carbon and energy impact of our services on the climate is an important and valuable objective for the strategic partnership between the stakeholders. Civil engineering can also be obstructive to local environments; therefore, the delivery team formulated a strategy to ensure the project left a positive lasting legacy for the local environment and community:

- Inclusion of the Environment Agency into the stakeholder management strategy to plan works through classified Watercourses in line with most appropriate and complimentary methods and planned dates.

- Utilising HVO fuel for all plant and equipment.

- Replanting of hedgerows and trees with native species.

- Preservation and protection of local habitats.

- Establishing tree protection zones and safety of trees subject to protection orders.

- Re-use of excavated material on site, reducing both landfill and vehicle movements.

- Off-site manufacturing.

IFAS steelwork installation – Courtesy of Trant Engineering

Project completion & summary

To ensure that the regulatory output was achieved and to mitigate against the resultant challenging timescales, the project delivery strategy included advanced procurement and critical enabling works for the major construction elements.

Works started on site in September 2023, and all regulatory outputs were achieved on 30 March 2025. This impressive achievement was due to the collaborative approach to project management, construction, and commissioning by all partners.

At the time of writing (July 2025) the works at Holdenhurst WRC are nearing completion. This complex but ultimately successful project ensures that future development growth can continue in the Bournemouth area with a significant improvement to the treatment process and quality of final effluent.

The project has been delivered to the highest quality and Health & Safety standards and is testimony an aligned project delivery team and wider supply chain.

IFAS steelwork installation - Courtesy of Trant Engineering