Llwyn Onn WTW (2013)

The original Llwyn Onn WTW was constructed during World War II, to supply water for a munitions factory in Wrexham. Water is abstracted from the Dee and pumped to the Marchwiel Reservoir before treatment at Llwyn Onn. Raw water quality is reliable, but the upland sources in particular result in high levels of manganese.

Although the works at Llwyn Onn has provided consistent service, age and structural condition dictated replacement. Manganese removal was another key driver. Rather than refurbishing the existing process plant an entirely new treatment system, housed in new structures, was deemed essential. The resulting £15.6m project was the largest single element of the utility’s AMP5 capital investment programme. It was not deemed necessary to increase the works’ 47.5Ml/d capacity

Background

Dee Valley Water (now Hafren Dyfrdwy) is one of England and Wales’ ten water supply only companies and was formed in 1997 with the merger of the Chester Water Company and Wrexham Water Company. Chester and Wrexham remain the largest population centres within the utility’s operating area. The utility serves approximately 258,000 customers in a 831km2 area of north east Wales and north west England. Dee Valley Water currently supplies 23 million tonnes of water per year. The River Dee is the utility’s principal source of water, supplying 90% of annual requirements. Water is also obtained from eight impounding reservoirs which are fed from collecting grounds on the local hills and around Llandegla, and two small groundwater sources.

Along with the impounding reservoirs the utility’s asset base includes 6 (No.) treatment works, about 2,000km of mains, 36 (No.) service reservoirs and 28 (No.) booster stations. Llwyn Onn,the largest of the treatment works, supplies 98,000 people in and around Wrexham.

Contract award

Integrated consulting and construction company Black & Veatch (now Binnies) has worked with Dee Valley Water for more than 20 years. Following a competitive tender process the utility awarded Black & Veatch the contract to undertake the design and construction of Llwyn Onn’s new treatment plant. Black & Veatch’s role encompassed the entire cycle of creating the new assets: planning, design, construction and commissioning. The contract was executed in two phases, beginning in April 2011. A six-month planning and design period, to reach a target cost, was followed by the construction period which was scheduled for completion in April 2013.

The treatment works is located atop a low hill and an 18ML storage reservoir is the largest of the existing structures. A designated ancient woodland, Mill Wood, screens the site’s north and western aspects. Although Llwyn Onn is bounded mostly by agricultural land, housing developments on Wrexham’s south east edge come within 150m of the site’s boundary at one point.

During the consultation phase residents registered concerns about the project’s visual impact. In order to accommodate their wishes, and achieve the best hydraulics to optimise pumping needs, it was decided that all new structures should keep below the tree line provided by Mill Wood.

New Process

Raw water quality dictated conventional treatment steps. The new process encompassed:

- Flocculation.

- Dissolved air floatation (DAF).

- Granular activated carbon (GAC) primary filtration.

- Rapid gravity filter (RGF) secondary filtration.

- Chlorine disinfection.

The RGF phase was included to reduce the levels of manganese. Black & Veatch’s design role was multi-disciplinary in scope including process; mechanical, electrical, instrumentation, controls and automation (MEICA); and civils. Design was undertaken by B&V’s Chester office working very closely with co-located members of Dee Valley Water’s project team.

New lamellas were part of the upgraded process plant – Courtesy of Black & Veatch

Meeting the client’s needs

Two factors were central to achieving a design that fulfilled Dee Valley’s needs. First was the ability to accommodate all of the new structures within the boundaries of the existing site; additional land-take was not an option. Second was that construction and operation of the new assets would not have an impact upon the integrity and operation of Llwyn Onn’s existing assets.

These factors placed significant constraints upon the size and location of the new structures; but through cooperation and innovation a viable design was achieved. The efficiency of the design phase, and effectiveness of its outcome, was boosted by using an integrated consulting, design and construction team from the same business.

Because they worked for the same company the design and construction teams had ready access to each other. This sped up problem solving and made design modifications more straightforward to implement. More importantly, the need for extensive design changes was averted, from the project’s early stages onwards, as a result of close dialogue between designers and constructors.

The factors which had the greatest influence upon design also created significant challenges during the construction phase. The need to accommodate all three of the new structures within the boundary of the existing site led to a very constrained working environment for the construction team. Ensuring this did not affect the tight programme required careful phasing of work so tasks could be undertaken without affecting adjacent working areas.

Construction issues

At the height of the project there were up to 150 construction professionals at Llwyn Onn. The size and shape of the site meant a wide variety of activities, often requiring heavy plant, had to be undertaken simultaneously within very close proximity to each other. This was further compounded by the imperative not to impinge upon the operation of the live works.

For example, accommodation had to be made for chemical deliveries to the existing works and challenging access meant the tankers had no option other than to be routed through the construction site.

An element of the existing works which had one of the most significant influences upon construction was the 18ML storage reservoir. Part of the original wartime works, the reservoir is vital to Llwyn Onn’s successful operation, and as a result it was important to ensure that the integrity of the reservoir was unaffected by the construction work.

A monitoring programme was established so the effects of vibration and earthworks upon the reservoir could be observed constantly. The constrained site meant that all of the new structures were within close proximity to the reservoir. This influenced the method of construction required.

The need to minimise vibration and ground movement meant piling was not an option for the footings. As a result it was necessary to prepare the ground by pre-loading. The soil was sandy, granulated and free draining which meant that the technique (where excavated material is piled upon the structure’s footprint to compress and stabilise the ground to be built upon) was a viable option.

Obtaining the best hydraulics, and the desire to limit the new structures’ height, also had an impact upon the construction of the new filter block. These factors lead to a significant proportion of the structure being below the hill profile. This required excavations to be an extra 5m deep in some places.

Once the primary filtration system was in-situ, initial testing indicated performance levels were not meeting expectations.

Further investigations revealed quality issues with some of the most critical components. Remediation of the primary filtration system as installed was not possible and wholesale replacement of the process equipment was the only way to achieve the performance required. The resulting additional costs were met by the original equipment manufacturer.

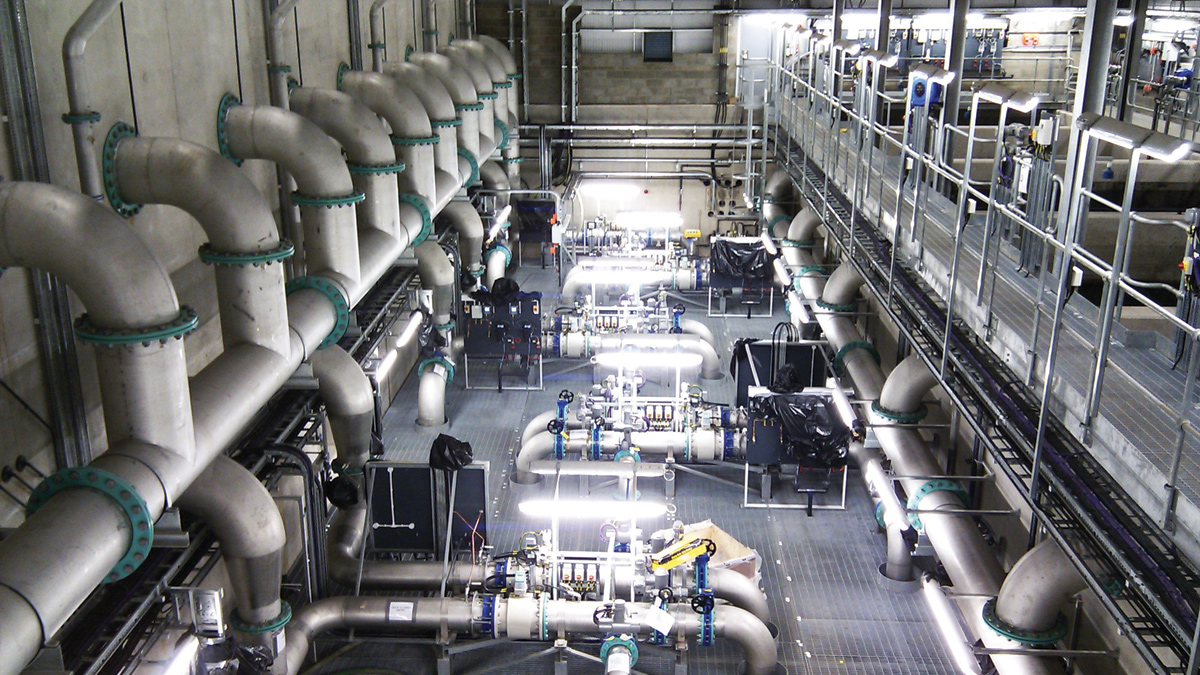

New low level pumping station downstream the new chlorine contact tank to feed the existing site service reservoir – Courtesy of Black & Veatch

Health & safety

The gold standard for health and safety was achieved at Llwyn Onn. Black & Veatch and Dee Valley Water were jointly presented with a gold award at the Royal Society for the Prevention of Accidents (RoSPA), Occupational Health & Safety Awards 2013. For a project to win a RoSPA gold at the first attempt is rare.

The fact the accolade was awarded jointly to client and contractor recognised how closely the parties collaborated to meet the not insignificant health and safety challenges the project presented. These were characterised by the need to safely undertake multiple simultaneous construction activities on a very space constrained live treatment works.

There were also health and safety benefits of using integrated consulting, design and construction teams from the same business. Black & Veatch’s award-winning Behaviour on Safe Sites (BOSS) behavioural health and safety programme encompasses design as well as construction teams. The result is close dialogue between the two teams, from the project’s formative phases onwards, with the goal of ‘designing-out’ risk from activities undertaken by those building and operating Llwyn Onn. The RoSPA gold is testament to the success of this way of working.

Conclusion

The new plant will be commissioned in August 2013 and provides long-term security and quality of water supplies for communities in Wrexham and the surrounding area. The project is another milestone in Black & Veatch’s 20-year relationship with Dee Valley Water.