Marsh Mills STW Stormwater Storage (2025)

The new Marsh Mill STW stormwater storage tank from Stortec Engineering Ltd - Courtesy of Galliford Try

Marsh Mills Sewage Treatment Works (STW), located near Plymouth, Devon, is a key part of South West Water’s wastewater network. The facility plays a role in treating wastewater for a catchment area that covers portions of Plymouth and its surrounding neighbourhoods. This includes both established communities and newly emerging developments, which continue to place increased demand on the infrastructure. Marsh Mills STW also operates as a sludge treatment centre, processing not only local sludge but also material imported from a number of smaller treatment sites across the South West. Its dual-functionality makes it an impressive asset by maintaining both high environmental and public health standards across the region.

Project need

Due to significant population growth, urban expansion, and the increasing frequency of intense storm events, the existing stormwater storage had reached its limits. In order to ensure continued compliance with environmental standards and improve customer experience, a strategic upgrade was required to increase the site’s storage capacity and manage storm flows more effectively.

The project’s main objective was to boost stormwater storage capabilities at the site through the construction of a new tank, which would allow for improved operational flexibility and performance during periods of high inflow. This was especially important in meeting the requirements of U_IMP6 regulations, which govern the way stormwater is handled in relation to environmental performance and service standards.

By incorporating forward-thinking design choices and embracing low-carbon, cost-effective solutions, this project aims to support the long-term sustainability and resilience of the Marsh Mills STW. It also contributes to South West Water’s broader goals of improving customer service, protecting the environment, and investing in future-ready infrastructure.

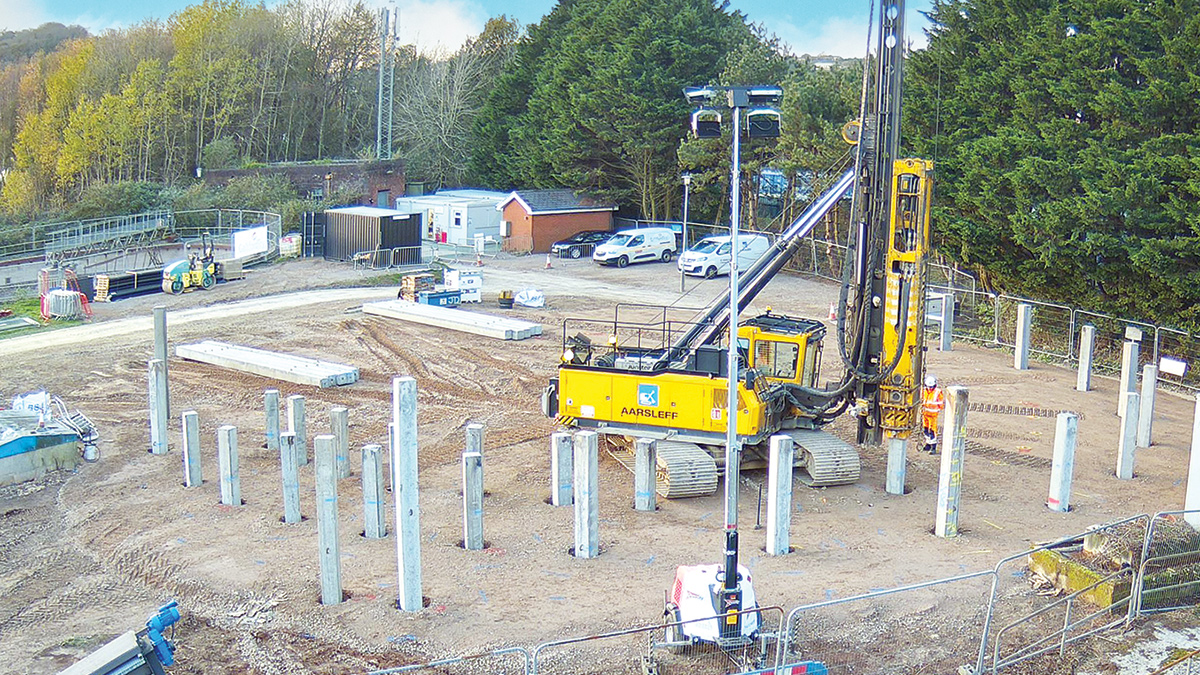

Overview of work area – Courtesy of Galliford Try

Project drivers

The rationale behind the Marsh Mills STW Stormwater Storage Project was multi-faceted, with several key drivers identified from the outset:

- Regulatory compliance: Ensuring the facility complies with U_IMP6 requirements by in-creasing stormwater storage capacity and improving the control of overflow during high in-flow events.

- Customer-focused outcomes: By expanding capacity, the facility can help reduce discolouration events during storms, thereby decreasing the number of customer complaints and improving service reliability.

- Population & housing growth: Ongoing development in Plymouth and surrounding towns has led to a rise in wastewater volumes. Increasing the site’s ability to handle stormwater is crucial to supporting this growth.

Optioneering

In the early planning stages, Galliford Try, in collaboration with South West Water, undertook a detailed assessment of the available options for increasing storage volume in the most efficient and sustainable way possible.

The team began by evaluating the current processes on site and how new infrastructure could integrate into the existing system without disrupting operations. Reducing carbon impact was a key focus from the outset. The use of MOATA, a digital platform that calculates and compares the whole-life carbon footprint of various infrastructure options, played a vital role in informing the selection process.

Several potential solutions were considered. These included underground shaft storage with gravity inflow and pumped return, as well as a number of above-ground storage tank designs using different materials. The team compared each option by looking at capital costs, long-term operational and maintenance expenses, and carbon impact.

Following this robust review, the most suitable solution was identified as an above-ground tank. This option offered the best balance of capital expenditure, operational efficiency, and carbon savings, making it the preferred solution for both client and contractor.

(left) Site set up and (right) piling mat – Courtesy of Galliford Try

Marsh Mills Stormwater Storage: Supply chain – key participants

- Main designer & contractor: Galliford Try

- Principal designer: Arcadis

- Physical modelling: Hydrotec Consultants Ltd

- Ground investigations: Ground Consultants Ltd

- Tank & base design & installation: Stortec Engineering Ltd

- Sewer & tank cleaning: Clearflow Ltd

- Piling contractor: Aarsleff Ground Engineering Ltd

- RC contractor: D Wall Construction Services

- Underground pipework: R2M Limited

- Mechanical installation: Drew & Co

- Mixing & pumps: Grundfos Pumps Ltd

- Ultrasonics: Pulsar Instruments

- Flow controls: AFFCO Flow Control (UK) Ltd

- Flow meters: Siemens

- Level instruments: IFM Electronics

- Kiosks: Quinshield Ltd

- Welfare units: Wernick Group

Design & construction overview

A new above-ground stormwater storage tank was constructed on site to provide the additional capacity required. This new infrastructure integrates with the existing network while offering enhanced performance during peak events.

Key features of the new tank include:

- Seamless connection into existing site infrastructure to allow for operational continuity.

- Foundations constructed using a specialist deep support solution tailored to the site’s challenging ground conditions.

- A return flow mechanism that directs stored stormwater back into the treatment process under controlled conditions, with integrated monitoring to optimise performance and maintain compliance.

Pile driving being undertaken by Aarsleff Ground Engineering Ltd – Courtesy of Galliford Try

Pumping & pipework

New pumping systems and associated pipework were installed to support the flow of stormwater between different areas of the site. This includes infrastructure to transport storm flows into the new tank and return treated or stored flows to the main process when capacity allows.

Storm tank operation

To ensure the storm tank operates efficiently, a number of flow management systems were installed. These systems help maintain water movement within the tank to avoid sedimentation and allow for easier reintroduction of stormwater into the main treatment process once storm conditions subside.

Control & instrumentation

A modern control and instrumentation suite was installed, including a new motor control centre (MCC) that allows for the fine control of equipment performance and energy usage. Monitoring devices were also included to provide real-time insights into tank performance and flow conditions.

Project schedule

- Mobilisation to site: 30 September 2024

- Commencement of piling work: 11 November 2024

- Tank base construction started: 2 December 2024

- RC works underway: 20 January 2025

- Start of tank installation: 27 January 2025

- MEICA fit-out: 17 February 2025

(left) Completion of piling and (right) piles cropped and blinding installed – Courtesy of Galliford Try

Construction challenges & innovations

A number of challenges arose during the delivery of the scheme, many of which were addressed through innovative thinking and collaboration.

- Ground conditions: The construction site presented a number of geotechnical challenges due to its proximity to marshland and the presence of contaminated soils. The chosen foundation method not only ensured structural stability but also mitigated the risk of disturbing hazardous materials, thus protecting the environment.

- Operational interface: Marsh Mills is a busy operational hub for South West Water, with day-to-day activities and routine services continuing throughout the duration of the project. Close coordination, proactive planning, and regular meetings with on-site personnel ensured minimal disruption.

- Carbon reduction: This project contributed to Galliford Try’s PAS2080 accreditation, which sets a framework for managing carbon in infrastructure. Throughout the construction phase, carbon was measured and monitored using tools to track plant usage, fuel consumption, transport distances, and material sources. Wherever possible, local suppliers were used, and efficient metering was installed to monitor site utilities.

- Innovative methods: Working with specialist supply chain partners, including Stortec Engineering Ltd, enabled the introduction of CNC-milled shuttering to improve the quality and consistency of concrete finishes. This innovation has since been adopted as a best practice for Galliford Try’s future projects.

Reinforced concrete works for the tank base designed and built by Stortec Engineering Ltd – Courtesy of Galliford Try

Cost savings & sustainability

A number of value-engineering approaches were adopted to balance functionality, cost, and sustainability:

- Tank sizing was carefully optimised to meet requirements without incurring unnecessary cost.

- The selection of materials, including a high proportion of recycled stainless steel, helped reduce the project’s environmental footprint.

- Long-term operational efficiencies are expected to reduce maintenance needs and running costs, delivering a lasting benefit to South West Water and its customers.

Summary & progress to date

The Marsh Mills STW Stormwater Storage Scheme represents a strategic investment in the resilience and sustainability of the region’s wastewater infrastructure. By expanding the facility’s ability to manage storm events, the project enhances service reliability, supports future growth, and ensures compliance with evolving environmental regulations.

The new above-ground stormwater storage tank from Stortec Engineering Ltd with rebate curing – Courtesy of Galliford Try

The project was complete for beneficial use by 31 March 2025.

The collaborative and innovative approach adopted throughout the scheme has set a benchmark for future upgrades, showing how environmental goals, technical excellence, and cost-efficiency can all be achieved in unison.