Meadow Lane Wastewater Pumping Station (2025)

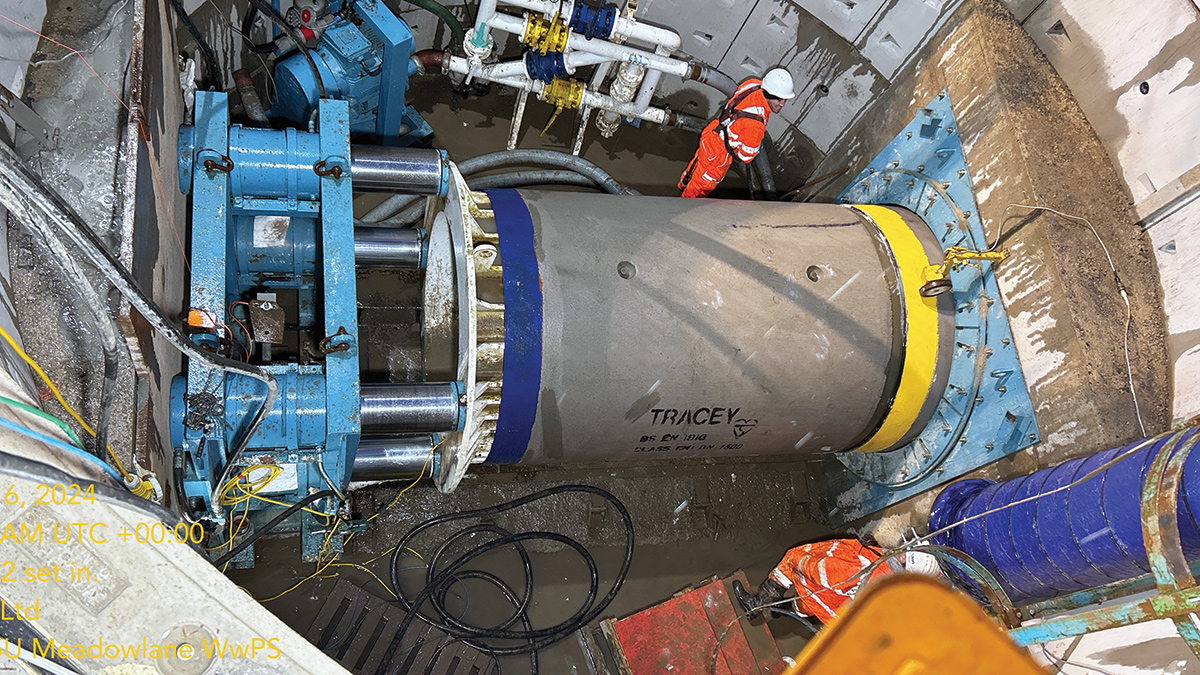

Unclemole TCP 1500 tunnel boring machine - Courtesy of BSG Civil Engineering Ltd

Portadown is a large town in County Armagh, Northern Ireland located approximately 24 miles south-west of Belfast and nestled along the banks of the Upper River Bann. Over recent years, Portadown has transformed from a historically industrial town into a modern hub with a rapidly growing logistics sector and retail environment attracting high footfall and continued economic growth. Meadow Lane Wastewater Pumping Station (WwPS), located within the central retail area of the town, was constructed in 1966. The site forwards flow to a downstream gravity sewer system before subsequently flowing into the southern inlet of Seagoe WwPS, approximately 1.5 miles away.

Need for upgrade

Meadow Lane WwPS was identified as requiring significant base maintenance interventions due to the antiquated nature and condition of existing pumps, pipework and control assets which require a high level of maintenance; thus, imposing a risk of potential significant failure. The following observations were made on site:

- Existing pumps showed signs of extensive wear (supported by observed power loadings).

- Control motors were identified as being installed pre-1975.

- The existing motor control centre (MCC) did not satisfy current asset standards.

NI Water Technical Support had also advised of occurrences of flooding within the dry well as a direct result of leaking pumps which required reactive maintenance and tankering operations.

Additionally, following completion of the 2007 Portadown Drainage Area Study, Meadow Lane WwPS was identified as a required output. It was outlined to NI Water the need for the existing Meadow Lane WwPS to deliver flow to full treatment (FFT) if the upstream network spill performances are to meet the Northern Ireland Environment Agency (NIEA) requirements for the Meadow Lane catchment area.

Secant piles with reinforced concrete capping beam – Courtesy of BSG Civil Engineering Ltd

Model updates were completed in 2016 following flow monitoring surveys, and further inspections confirmed that the existing pumps could not deliver the required FFT. Therefore, the five CSOs identified by the NIEA as Unsatisfactory Intermittent Discharges (UIDs) could not be closed without significant intervention/upgrade at Meadow Lane WwPS. Model updates were also completed in 2020 to reflect predicted future 2040 flows.

The NIEA had identified the following five CSOs as UIDs:

- Meadow Lane One CSO.

- Meadow Lane Two CSO.

- Portmore Street CSO.

- Clonavon Avenue CSO.

- Meadow Lane Health Centre CSO.

Failure to address spills would lead to potential prosecution by NIEA and associated reputational damage due to potential serious sewage flooding and pollution to the Annagh River, Upper River Bann and the surrounding area.

Early Contractor Involvement (ECI)

NI Water appointed BSG Civil Engineering Ltd as the main contractor under an NEC3 Early Contractor Involvement (ECI) Contract. As the main contractor, BSG provided multi-disciplinary design, project and supply chain management and civil engineering and MEICA works for the contract from inception to completion.

The ECI phase allowed BSG to align resources and integrate objectives with the client, NI Water, and project managers, McAdam, at an early stage to benefit overall project delivery. This allowed for enhanced collaboration, innovation, value, efficiency and reduced whole life cycle costs for the project.

Liner wall formwork using Peri Rundflex – Courtesy of BSG Civil Engineering

Meadow Lane WwPS: Supply chain – key participants

- Project delivery: BSG Civil Engineering Ltd

- Civil, hydraulic & process designer: McAdam

- Temporary works design: MEA Ltd

- Earthworks: BSG Civil Engineering Ltd

- Specialist piling contractor: Quinn Piling Limited

- Formwork: Peri UK

- Reinforced concrete works: ONCCE Ltd

- Tunnelling contractor & TBM: B&W Tunnelling Ltd

- Open cut pipe installation: Phace Contracts Ltd

- Open cut pipe installation: O’Neill Contracts & Plant Hire

- Open cut pipe installation: AG Wilson Civil Engineering

- Groundworks: RMG

- Metalwork & FST designer/installer: RJ Smyth Engineering

- Precast roof beams: Macrete (Ireland) Ltd

- Precast roof slabs: Creagh Concrete

- Precast concrete pipes: Tracey concrete

- Screens: Eliquo Hydrok Ltd

- Submersible pumps & float switches: Xylem Water Solutions

- Flow meters: Siemens

- Control panels: Motrol Ltd

- Kiosks: Quinshield Ltd

Primary drivers

The purpose and drivers of this project were as follows:

- Ensure a reduction in spill frequency and volume through the provision of adequate storage facilities within the Meadow Lane catchment area.

- Closure of the five unscreened UIDs (identified by the NIEA) and subsequent provision of sewer upgrades in the upstream catchment to transfer flows from the closed UIDs and provide online storage.

- Resolution of three DG5 properties within the Meadow Lane area.

- Essential replacement of Meadow Lane WwPS with provision of a screened emergency overflow.

Pouring of 400m3 base slab – Courtesy of BSG Civil Engineering

What the upgrade involved

The upgrade of Meadow Lane WwPS and the associated network was a large-scale infrastructure project located within a complex urban environment. The project saw:

- The installation of 380m of 1,500mm diameter tank sewer approximately 7m below ground level.

- The installation of 350m of sewers ranging in diameter from 300mm to 1500mm via open cut techniques in depths ranging from 2m to 7m below ground level.

- The demolition of the existing Meadow Lane WwPS.

- The construction of a new inlet chamber, wet well pumping station and 1,500m3 storage tank at the existing Meadow Lane WwPS site.

- The installation of a new MCC panel and associated glass reinforced plastic (GRP) kiosk.

- The installation of three 37kW foul pumps and two 9kW hydro ejectors.

- The installation of three screens from Eliqua Hydrok Ltd.

- The closure of five unscreened UIDs.

1,500mm tank sewer installation

Meadow Lane is an arterial route through Portadown town centre, providing access to several shopping facilities, restaurants and medical facilities. It was identified that significant traffic management, potentially involving lengthy diversions, would be required for an extended period to undertake the installation of the 1,500mm diameter tank sewer along Meadow Lane using open-cut methods.

Pipejacking operation within launch pit – Courtesy of BSG Civil Engineering

Therefore, it was determined that a trenchless pipejacking method of installation would be adopted to install the full 380m of 1,500m tank sewer. Additionally, the use of a tunnel boring machine (TBM) would allow for a reduced potential environmental impact due to the reduction in surface disruption, dust, noise and vibrations; and provide enhanced safety for construction staff due to the automated installation process.

Due to the unstable ground conditions, a closed face slurry system was used as this technique allowed the area around the TBM to be supported with a pressurised bentonite mix, preventing collapse and ensuring stability. During this process the excavated material was pumped from the face of the TBM, through the installed tunnel, to an above-ground separation system where the excavated material was removed from the bentonite mix, allowing it to be recycled and returned to the tunnel face for reuse.

The tunnelling operation was undertaken in three stages with launch and reception pits installed to facilitate each drive stage alongside ancillary tunnelling operations; drive stages varied in length between 70m to 230m. Due to the varying and difficult ground conditions present along the proposed tunnelling route, launch pits and reception chambers were installed using a combination of both segmental shafts and traditional cofferdams.

Storm retention tank, inlet chamber & wet well pumping station

The storm retention tank, inlet chamber, and wet well pumping station was designed as one structure. Due to the difficult ground conditions, high water table and proximity to existing NI Water assets, it was determined that secant piling would be implemented as a means of providing temporary support to facilitate safe excavation.

Installation of concrete beams – Courtesy of BSG Civil Engineering Ltd

A specialist piling contractor was utilised to install 140 (No.) 750mm diameter secant piles to a depth of 18m below ground level before the installation of a reinforced concrete capping beam to complete the excavation support system. Once installed, the secant piled wall provided a watertight structure. Localised dewatering within the secant piled structure was used to ensure excavated material remained dry and suitable for reuse on site. Approximately 3500m3 of material was removed from the 21m diameter, and 10m deep excavation.

Construction of the storm tank consisted of a 1200mm deep reinforced concrete base, a 400mm thick external liner wall, and a 500mm internal dividing wall. The liner wall formwork was designed as a single sided system using Peri Rundflex and constructed in two lifts to meet temporary works restrictions.

The roof structure was constructed using 1250mm by 900mm precast beams and 450mm thick precast hollow core slabs. Structural screed was then poured to complete the structure.

The complex roof slab arrangement consisted of a variety of construction techniques including in situ reinforced concrete elements, precast concrete primary and secondary beams, structural steel beams and hollow core precast slabs. The complete design of the roof structure was provided by five different design companies working in collaboration ensuring each element adhered to the tight tolerances required for accurate placement.

Open cut sewer installation

Six sections of open-cut sewer installation were completed in this scheme. Boxed systems were used to provide temporary works excavation support for the pipe installations. Sewers were installed to depths of up to 7m below ground level in sites with limited working room. Traffic flows were controlled by complex traffic management systems.

Open cut sewer installation at Manhole No. 4 – Courtesy of BSG Civil Engineering Ltd

MEICA installation

The MEICA installation was completed in two stages. A new MCC was installed within the new GRP kiosk, and once all building services were installed, the NI Electricity supply was diverted to the new MCC panel which then backfed a supply to the existing MCC panel until turn of flows in April 2025.

Once civils construction had sufficiently advanced, the second phase of the mechanical fit out commenced, where the three 37Kw foul pumps and associated pipework were installed from the foul pumping station to the flow meter chamber. A 250mm Siemens MAG 5100w was then installed to measure the outgoing flow-rate. Two pump stools, 9Kw hydro ejectors and pipework were installed within the storage tank to jetwash the tank during storm events.

Three Eliquo Hydrok Ltd screens were installed into the following areas:

- Inlet screen chamber: 600l/sec Mecmex™ screen.

- Foul pumping station overflow screen chamber: 70l/sec static Peak Screen™.

- Storage tank overflow screen: 264 l/sec static Peak Screen™.

Pump remote enclosures and actuators – Courtesy of BSG Civil Engineering

Additional construction challenges

The main challenges faced during the delivery of Meadow Lane WwPS were a combination of site-specific constraints, environmental constraints and equipment/asset failures during the construction period. Some of the additional challenges experienced during the construction stage have been outlined below.

Portadown has been identified within the Northern Ireland Flood Risk Management Plan as an area of significant flood risk, due to regular fluvial flooding from the Upper River Bann and its tributaries. The most recent significant flood event was recorded in 2024, which saw substantial flooding across the entire work site. This fluvial flood event led to a halt in works on site for approximately one week and caused damage to plant.

The 500mm diameter outlet pumping main from the existing Meadow Lane Pumping Station ruptured on two occasions during the construction programme. To carry out the repair on the outlet pumping main, both Meadow Lane and Annagh WwPS had to be shut down and seven tankers were mobilised to transfer effluent to other NI Water treatment facilities. BSG Civil Engineering Ltd was able to utilise the newly constructed storm tank to create temporary storage and prevent any out-of-sewer flooding during the emergency repair works. BSG received positive feedback from NI Water on how these critical network emergency repair works were managed and rectified in a safe, collaborative and timely manner.

(left) Fluvial flooding event in 2024 within the site compound, and (right) utilising the new storm tank for temporary storage following an outlet pumping main failure – Courtesy of BSG Civil Engineering Ltd

Stakeholder communication

NI Water and the project team recognised the potential negative impacts which could arise from undertaking such a large-scale project within a busy town centre location and from an early stage embarked on a strategic communications strategy to ensure key stakeholders were informed of the works and kept updated throughout.

As part of the public relations programme the project team and NI Water Communications held early briefings with a range of stakeholders including elected representatives, town centre management, chamber of commerce, health care centre, council, roads authority, landowners and local businesses.

In addition to the numerous one-to-one meetings, letter drops were carried out in advance of each section of road works commencing and press releases issued to the local media to advise the wider public of traffic management. Variable message boards were erected on main routes and large-scale project boards helped to convey the huge investment being made by NI Water and the resulting benefits for the public.

Key project milestones were publicised along with facts and figures relating to the construction work and tunnelling exercise.

Regular project updates and lookahead bulletins were issued to stakeholders to keep them up to date on progress and advise them of future traffic management requirements. Town centre management were invited to site at key stages of the project to view progress and hear firsthand about the benefits the NI Water investment will bring to Portadown.

BSG provided a point of contact for operational queries and this, along with NI Water’s wider stakeholder communications, helped to ensure a smooth-running construction programme.

Completed Meadow Lane WwPS (July 2025) – Courtesy of BSG Civil Engineering Ltd

Outcomes

NI Water directed significant financial investment into upgrading the existing sewer network and Meadow Lane WwPS within the Meadow Lane area of Portadown. The proposed works oversaw the closure of five CSOs within the Meadow Lane WwPS catchment area through connection into the new 1,500mm tank sewer alongside the resolution of three DG5 properties.

The collaborative effort between NI Water, BSG Civil Engineering Ltd and McAdam resulted in the smooth completion of the programme and successful testing, commissioning and handover to NI Water in July 2025. The benefits of the new infrastructure will be realised almost immediately through a reduction in spill frequency and volume within the Upper River Bann and Annagh River.

This project showcased the capabilities of NI Water, BSG Civil Engineering Ltd and McAdam to coordinate and undertake sensitive high-risk activities such as a large-scale turn of flow without issue and within a complex urban environment.