Red Doles CSO (2024)

Hydraulic powered screens - Courtesy of MMB

The Red Doles Combined Sewer Overflow (CSO) neighbours the Huddersfield Broad Canal and a Network Rail bridge. The CSO serves a catchment covering approximately 3.8km2, predominantly consisting of residential properties and accommodating around 8512 people. The majority of the Fartown area of Huddersfield drainage operates as a combined system, with Red Doles receiving flows from this catchment. The existing ‘bunker style’ CSO chamber is 14m x 5m, was built in 1970, and contained a mechanical/electrical bar and rake screen. The existing screen had reached the end of its asset life and required replacement to ensure compliance with the discharge consent.

Project scope

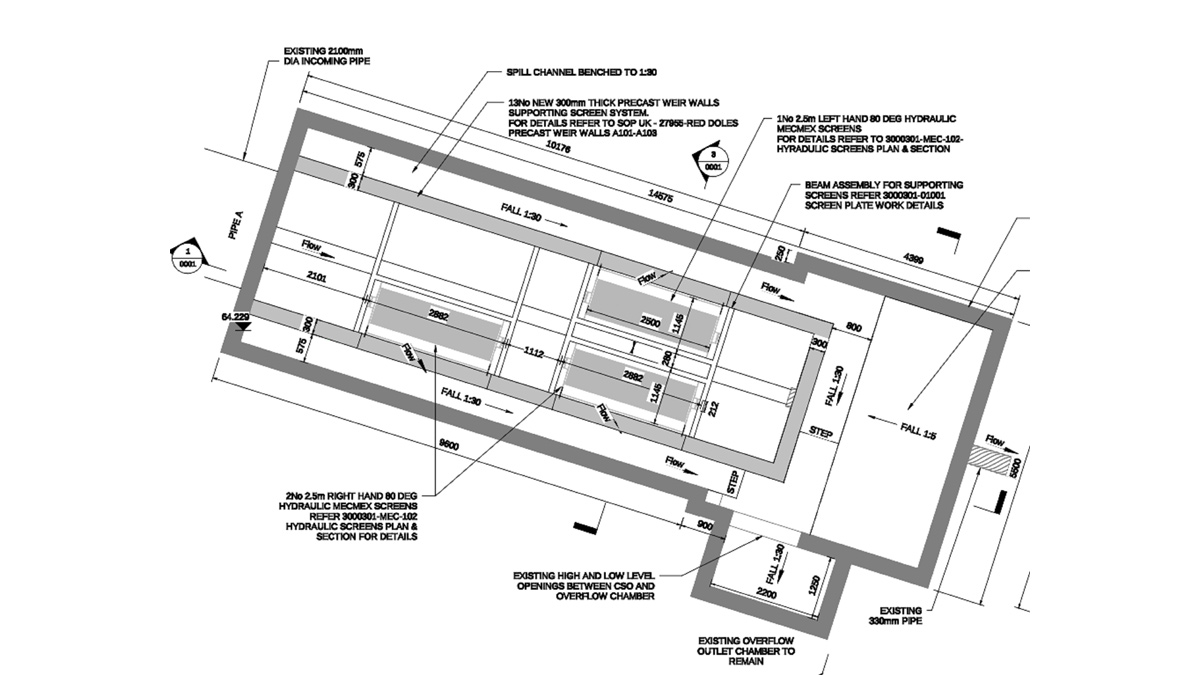

Mott MacDonald Bentley (MMB) was instructed by Yorkshire Water to undertake the refurbishment of the existing CSO chamber, which involved installing three new 2.5m hydraulic screens from Eliquo Hydrok Ltd along with associated electrical components. Structural modifications to the chamber were necessary, including the removal of the existing concrete weir wall and roof slab, installation of new precast weir walls, re-benching of the existing chamber, and installation of a new precast cover slab to enable installation of the three new screens. Additionally, the project required the removal of a brick control building, disconnecting the power supply, and installing two new security-rated GRP kiosks for hydraulic power packs and a control panel along with a new power supply.

Challenges

The project encountered several challenges to overcome during the design and delivery works including:

- Flow conditions working within an active sewer.

- Working near Network Rail assets undergoing maintenance.

- Significant works to the existing structure.

Working area – Courtesy of MMB

Temporary works

With the potential for large flows within the catchment, the temporary works were critical in ensuring a safe construction sequence in the CSO chamber whilst not impeding the impact of the existing system. A temporary dam was constructed within the upstream 2.1m diameter pipe with a flume pipe and valve attached.

This allowed normal flows to pass straight through the CSO to the outfall without impacting on the construction work. During high flows, the dam allowed the system to store flows and still pass forward flows before the any flows spilled from the CSO. This arrangement was used while the internal structural elements were removed from the CSO. Once the new precast concrete weir walls where installed the flume and dam could be removed, still allowing the system to react to high flows as required, ensuring that there was no detriment in the catchment.

Network Rail

The location of the CSO, neighbouring a Network Rail overbridge, introduced limitations on the construction methodology that could be carried out. Network Rail also had a significant programme of works in the area, adding a second line to the network. This work included widening the existing adjacent overbridge and using large cranes to lift equipment up to track level from road level. This crane was planned to be positioned next to the CSO chamber, with outrigger zones of influence extending into the CSO footprint.

Through close liason with Network Rail contractors and detailed discussion about both schemes, MMB was able to ensure full access to complete the works before Network Rail started their scheme. This also allowed Network Rail contractors to inspect the entire CSO structure, once exposed during its construction, helping them to develop their lifting plans for their own scheme. As a result of this cooperation, both schemes were completed successfully.

CSO chamber general arrangement – Courtesy of MMB

Red Doles CSO: Supply chain – key participants

- Client: Yorkshire Water

- Principal contractor & design support: Mott MacDonald Bentley (MMB)

- Design of CSO upgrade: Stantec UK

- Hydraulic screens: Eliquo Hydrok Ltd

- Precast weir walls & cover slab: FLI Precast Solutions

- Kiosks & control panel: Saftronics Ltd

- Electrical subcontractor: Circle Control & Design Systems

- Access covers over screens: Technocover

- Concrete cutting: Optima DS

- Fall prevention: J-Safe Ltd

Removing the existing roof

The existing 1970s chamber was robustly built with thick walls and benching requiring break out to install new weir walls, roof slab. As the existing chamber was constructed in situ with a roof slab and wall that appeared to be structurally tied together, a temporary works consideration was required for when the roof was removed.

As the wall could be acting as a propped cantilever, removing the roof could result in additional stresses to be put on to the walls. By carrying out an assessment of the walls it was determined that the existing robust walls were suitably constructed to allow for no additional propping during the temporary removal of the roof. Using various techniques, including coring and track saw’s MMB were able to remove the roof slab providing safe unrestricted access into the chamber enabling construction of the internal structure and installation of the new screen.

CSO modifications

MMB adopted a Design for Manufacture and Assembly (DfMA) approach throughout the modification of the CSO. Precast concrete weir walls with infill stitches from FLI Precast Solutions were used for the new weir walls; suitable for the new screen arrangements and providing quality and time savings compared to traditional in situ installations. The screens, which were manufactured off site, could be lifted and bolted into place, reducing assembly on site within the chamber. Finally, the cover slabs were specially manufactured to fit the unique chamber size, providing self-supported slabs with the necessary maintenance and inspection openings.

(left) Installation of the weir walls and (right) installation of the roof slab – Courtesy of MMB

Along with off-site manufacturing, MMB also opted for the online factory tests for the screens and control panel. These approaches employed in the project, not only contributed to the safer construction works, but also had a positive impact on reducing overall carbon emissions. By minimising on-site concrete work, the project reduced energy consumption and overall carbon footprint.

Collaborative working & successful completion

The project benefited greatly from the early involvement of all the manufacturers and collaborative work throughout the delivery. Further, the project showed the significance of conducting technical and constructability reviews on temporary and permanent works. By identifying these limitations through reviews, it enabled the realising and inclusion of quality, environment, safety, and sustainability opportunities which were included in the design and delivery works.

MMB successfully completed the refurbishment works to high standards, earning commendation from the client. This case study exemplifies the significance of effective project management, problem-solving, effective communication, and collaborative working in overcoming complex engineering challenges.

Finished site - Courtesy of MMB