Saltend WwTW (2017)

Saltend WwTW aerial - Courtesy of Morgan Sindall Sweco JV/Suave Aerial Photographers

Yorkshire Water’s Saltend WwTW had a history of environmental under-performance which resulted in a significant number of customer complaints due to odour. Between September 2015 and May 2016, £18m of refurbishment and upgrade work was carried out on a fast track basis to improve this performance. Commercial arrangements were adjusted from normal framework conditions to suit the collaborative approach required to deliver the changes to the works that were necessary in the condensed timescales. Following this investment, the plant has experienced its best ever environmental performance during the peak season of the 2016 summer period, with only a single verified odour complaint (non-process related) received. Yorkshire Water also received complimentary feedback from both the local council and customer groups. Subsequent to the works, the plant has seen a 20% reduction in total power consumption and associated carbon footprint. The collaborative delivery model was also viewed as great success and Yorkshire Water are reviewing opportunities and criteria for using a similar delivery model is they move towards AMP7.

Saltend WwTW

Saltend WwTW was built in 2001 and serves a population (Hull) equivalent of over one million, with more than 50% of the incoming load from trade discharges. The works receives flows of up to 22,000 l/s to its inlet pumping station via an 8.8km long 3.6m diameter tunnel.

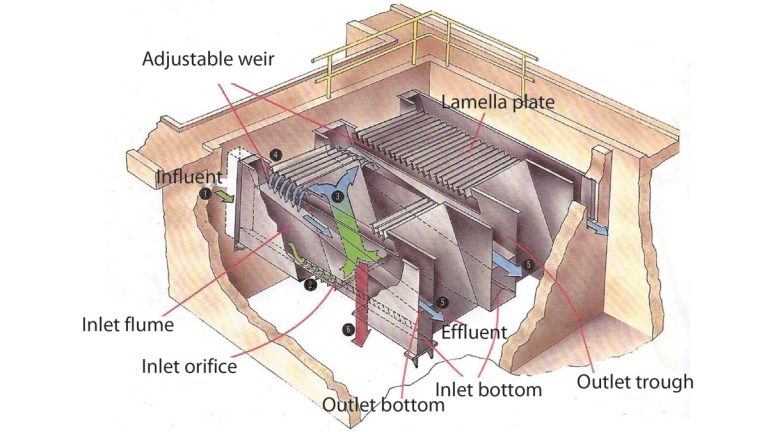

The works treats a flow to full treatment of up to 2000 l/s utilising small footprint technology, including lamella primary settlers and sequencing batch reactors (SBRs).

The final effluent consent requirements are 25mg/l BOD (or 70% removal) and 125mg/l COD (or 75% removal). Final effluent is discharged to the River Humber. The primary and secondary sludges are thickened, digested and dewatered. The resulting sludge cake has lime added before being removed off site for use on the land. There are 4 (No.) lamella settling tanks which utilise inclined plates to increase the settling area. The plant has 8 (No.) SBRs (each 42m diameter with 10m water depth) as the secondary treatment process to biologically remove the contaminants remaining in the wastewater from the lamellas.

Typical lamella schematic – Courtesy of Aquability OPS Ltd

Prior to the upgrade, the SBRs were aerated using jet aeration. Each SBR was provided with 3 (No.) jet aeration headers and 3 (No.) mixing pumps. 5 (No.) 600kW HV Turbo blowers deliver air into a common manifold (duty/duty/duty/duty/standby). The required air flow was delivered to each SBRs jet aeration header from the common manifold, controlled by an air control valve.

The SBRs operate in a cycle which is continually repeated. Each basin is in a different time in the cycle and there is only one basin filling at any one time. The cycle at Hull was circa four hours and comprised five stages:

- Fill (static and aerated)

- React

- Settle

- Decant

- Idle

Collaborative investigation model

The approach to this project was different to the conventional approach (ordinarily the award of an investigation contract followed by a risk based delivery contract).

Whilst the investigation (and delivery) approach was retained, Yorkshire Water adapted it to include three key phases:

- Problem clarification: The scheme was initiated by Yorkshire Water in August 2015 with a 3-day workshop to understand the problems to be solved using all available data. The workshop drew on Yorkshire Water’s AMP6 Framework partners who provided ‘subject matter experts’ to assimilate knowledge and identify a prioritised list of remediation measures.

- Scoping phase: a specially formed collaborative multi-party team (the scoping team) consisting of Yorkshire Water, specialist engineering consultants Arup, Aquability OPS Ltd, MWH (now Stantec UK), Turner & Townsend, and Yorkshire Water’s T1CPs (Tier 1 Contract Partners) was established to allow detailed design to progress in advance of a delivery contract. This approach greatly accelerated the speed of construction delivery.

- Delivery phase: Conventional delivery scheme by MS2JV (Morgan Sindall Sweco Joint Venture).

The team was located at the Saltend site to ensure close collaboration, ownership of the problems and to establish a commitment that the team would ‘fix’ Saltend together by 31 May 2016. Key to driving the tight timescale was the acceptance of process risk by Yorkshire Water thus removing the requirement for MS2JV to undertake extensive investigation works. There were two contract formats employed:

- NEC3 Option E (emergency works) for the workshop and scoping phases.

- An amended version of NEC3 Option C for the delivery phase batch.

The Option E contract was used to work with multiple organisations in the initial scoping phase.

In the delivery phase, the NEC3 Option C contract was amended and a mechanism was incorporated to allow the contract value to be increased in phases from an initial £2.5m up to its final value as new work scope was identified and approved. The amended contract and change mechanism enabled Morgan Sindall Sweco JV to accept the initial target cost and allowed for early contract signature.

SBR FBDA (fine bubble diffused air) installation – Courtesy of Aquability OPS Ltd

Scope of works

The scoping phase focused on developing the list of interventions identified at the initial design workshop into packages of work to be delivered by the Morgan Sindall Sweco JV. The main packages were:

- Odour control

- Inlet pumping station new odour control unit (OCU) by Air Technology Systems (ATS Climate).

- Primary treatment (Lamellas)

- New assets to enable chemical assisted precipitation in lamellas; new desludge pumps; refurbished and modified lamellas (NPS).

- Secondary Treatment (SBRs)

- Control philosophy modifications; conversion of jet aeration system to fine bubble aeration (Suprafilt).

- Enhanced dissolved oxygen (DO) and redox instrumentation; a change of air control valves to plug valves; replacement air flow meters; decanter isolation plug valves; refurbish decanters and modulating valves (Staptina).

- Improve control and availability of air blowers (TCS).

- Efffluent turbidity monitoring on each SBR (Hach Lange).

- Pre-treatment at source

- Pre-treatment at a large seasonal trader.

Collaborative delivery model

The collaborative model was taken into the delivery phase of the contract with the client, the scoping team, the supply chain partners and MS2JV staff all remaining co-located at Saltend. The MS2JV design team also moved to site such that they could coordinate and develop the design with the supply chain partners and scoping team.

In order to fast-track the design and avoid any duplication of effort MS2JV worked closely with the supply chain partners to clearly define the scope and limits of their design. Several of the supply chain partners were given early works contracts ahead of their main orders, this to allow them to progress the design in line with the tight timescales. At one stage or another, representatives from MS2JV, Circle Control & Design Systems, NPS, ATS, Nomenca (now Galliford Try), Suprafilt, CEMA, TCS, Staptina, Ward & Burke, Waitings and EMS were all based in the co-located office developing their elements of the design.

Close collaboration allowed the teams to develop the design with continued reference back to the decisions made by the scoping team. YWS’s operational team were also based in the co-located office, providing continuous input to the design both informally and through the design reviews and the HazOp and HazComm meetings. Extensive use of CLIP (Construction Lean Improvement Programming) was made to build, refine, improve and communicate the planning of the works.

(left) CLIP in action and (right) Mindsafety stand down event – Courtesy of Morgan Sindall Sweco JV

Key factors for success

- Frequent (often daily) programme review sessions were held to ensure any programme movement was understood and mitigated.

- Weekly cross-party ‘Hub’ review of performance dashboard was undertaken.

- The appointment of a full time dedicated Yorkshire Water team to support partner activity, ensures rapid decision making and engenders overall team spirit and collaboration.

- An independent third party undertook periodic peer reviews.

- The team was based at Saltend in a large site set up. This created adequate space and facilitated a high level of collaborative working from all stakeholders.

- Continuity of key staff was retained throughout the lifecycle of the project.

Supply chain involvement

As with all large projects supply chain collaboration was key to the successful delivery. The supply chain was involved throughout the project and was given early visibility as to the scope and nature of the works at a ‘whole team’ initiation workshop. The workshop allowed the supply chain to engage in understanding the issues, significance of the project and timescales. During the workshop a clear project charter was developed that all supply chain partners were invited to sign up to.

The collaborative approach was continued throughout the delivery phase with partners given access to the site office which allowed for team working, engagement and support.

Treatment at Saltend

Prior to the initial workshop, an odour survey was carried out by MWH, identifying that 54% of the odour generated was from the SBRs and 42% from the inlet pumping station. Further review of the lamella’s and SBRs identified that the main issues causing the odour generation and poor performance were:

- SBRs were overloaded due to poor BOD and solids removal in the lamellas.

- Major issues with SBR control (resulting in inadequate aeration and solids carryover in the final effluent).

- Inefficient SBR aeration (jet tech system), unable to satisfy the biological oxygen demand of the wastewater (resulting in septic conditions).

Reducing the odour at the inlet pumping station: To reduce the odour, a carbon filter OCU (odour control unit) was installed by ATS to treat 20,000m3/hr of air. Hydrogen sulphide concentrations were monitored in the vent stack. When levels reached a pre-set limit, the 30kW duty/standby OCU vent fans started to treat the odorous air through the carbon filter before it was discharged to atmosphere.

This approach meant the life of the carbon was maximised and prevented unnecessary operation of the fans with their associated power consumption.

Lamella plant – Courtesy of Morgan Sindall Sweco JV

Improving lamella performance: In order to improve lamella performance as quickly as possible, and allow the optimum chemical dose rate to be determined a temporary modular plant was also adopted at the Saltend WwTW where MS2JV utilised a modular chemical dosing plant (supplied by NPS) and chemical storage tanks (BakerCorp). The use of temporary modular plant allowed for the provision of ferric and polymer dosing ahead of the permanent works installation.

The lamellas had enclosed inlet flumes with small orifices that fed the wastewater into the lamella plates. These orifices were prone to blocking up. The blockages were causing poor flow distribution and high velocities between the plates which caused solids to carry over with the effluent.

The solution was to cut large ports in the bottom of the enclosed inlet flumes (from Staptina Engineering Services) so that any screenings/large solids would fall straight in to the bottom of the tank and be removed with the sludge. The wastewater could then flow evenly between the plates, unhindered.

Following the modification, removals increased more than two-fold and approximately 60% solids and 40% COD removal was achieved with a dose rate of 5-10mg Fe/l.

To facilitate the removal of the increased quantities of sludge from the lamellas, each lamella was fitted with a new RAM pump (EMS) and dry solids monitor. Revised desludging control maximised solids removal whilst maintaining sludge concentrations at around 1-2%DS. This allowed the downstream sludge thickening process to be optimised and resulted in a 7% increase in gas production from the digesters.

Providing robust, reliable and healthy SBRs: The existing SBR control system had various defects that included:

- Poor dissolved oxygen (DO) and blower control resulting in low DO (leading to odour generation and effluent failure).

- Excessive stop/start and failure of the blowers.

- Poor decanter control leading to solids carryover and effluent failure.

- Insufficient cycle time to treat high loads.

A revised SBR control philosophy was developed by Aquability OPS Ltd and Cougar, utilising three cycles (6, 5.3 and 4 hours respectively) to treat the wastewater, with a unique method of switching between cycles. This approach maximised the time available to treat the high loads. The dissolved oxygen, blower and decant modulating valve control was also modified to overcome the identified issues.

SBR in aeration – Courtesy of Morgan Sindall Sweco JV

Under high load conditions, there was insufficient blower capacity to satisfy the oxygen demand with the jet aeration system. The jet aeration system was susceptible to nozzle blockages, and also caused floc shear and poor sludge settleability. In order to increase the aeration efficiency and reduce the air flow requirements, the jet aeration systems (headers and mixing pumps) were replaced with a robust stainless steel fine bubble diffused air (FBDA) system from Suprafilt.

Each SBR was equipped with 886 tube diffusers. These modifications have had a significant effect on the SBRs performance and power consumption. The increased efficiency of the FBDA has reduced air flow requirements by more than 50%. Aeration power requirements have reduced by 625kW with a 20% reduction in overall site power consumption.

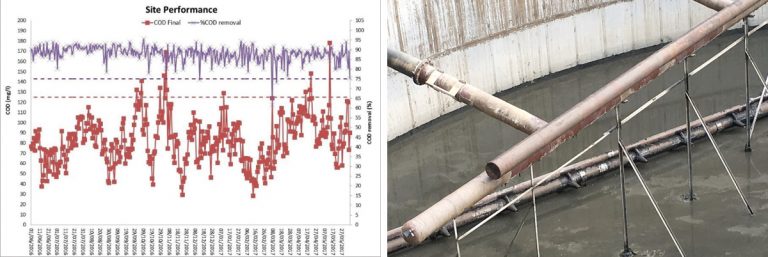

The plant has been in compliance for over eighteen months. Since completion of the upgrade, the plant has achieved an average COD of 82 mg/l and 85% removal. Settleability has improved with SSVIs reducing to < 70ml/g. The process is now very robust, maintaining compliance even when operating on only six of the eight basins.

(left) Site COD performance and (right) SBR Jet Tech – Courtesy of Aquability OPS Ltd

Treatment at source/network type solution

As part of the solution the team adopted a ‘treatment at source’ network solution. This involved the installation of a temporary treatment works within the catchment to deal with peak flows.

MS2JV worked with Arup and Siltbuster Ltd to design a temporary modular treatment works that was utilised to treat high loads at source and provide resilience to the Saltend works. The modular temporary treatment works, designed to treat an average flow of 208m3/hr, comprised:

- Flow control tank.

- Balance tank.

- 2 (No.) DAF units.

- Sludge dewatering unit (centrifuge).

- Sludge storage tank.

- Chemical dosing container.

- Chemical storage tanks.

The team designed the plant to include a number of Siltbuster Ltd’s ‘standard product’ treatment units as well as the flow control and balance tanks that were designed and manufactured specifically for the Saltend project. The sludge dewatering unit was supplied by MSE Hiller and the chemical storage tanks by BakerCorp. The installation works involved extensive site preparation that included drainage and concrete hardstanding. The narrow elongated nature of the site required extensive logistics management to ensure the units arrived on site in the correct order and that they could be safely lifted into position.

The modular nature of the plant allowed MS2JV and Siltbuster Ltd to adopt factory-type principles in sequencing the build and con-current MEICA activities. Commissioning of the plant started within one week of the first modular unit being delivered to site. In addition, MS2JV operated the temporary treatment plant.

(left) Treatment at source plant and (right) treatment at source plant – Courtesy of Morgan Sindall Sweco JV

Interface with Saltend WwTW operations

The project team was very well supported by the existing Yorkshire Water Saltend operational team; they were very much brought into the collaborative approach. A section of the operational team was permanently seconded to the project team and co-located within the collaborative office. This approach greatly benefitted the project. Notable areas included:

- Granting of permits.

- Coordination of other works on site, direct for Yorkshire Water.

- Daily operational status of the site.

- Assisting with fact finding on the existing site.

- Commissioning support.

- Advice.

The continued support of the Saltend operations team was key success factor.

Collaborative approach to safety

The approach to the safe delivery of the works with a challenging timescale was managed with a consistent and shared approach by all involved, and helped develop good safety culture and behaviours.

Safety was paramount in the delivery of the works in the short timescales. MS2JV organised a daily safety coordination briefing that was attended by all on site. The focus of the briefing being to ensure that everyone knew what activities were taking place, that permits/safe systems of work were in place and approved and to ensure the coordination of site activities/logistics etc.

As well as the day-to-day management of safety the MS2JV management team implemented a number of safety measures that included:

- Safety leadership tours.

- Feedback as regard positive interventions.

- ‘You Said, We Did’ boards – indicating how MS2JV had responded to feedback.

- Mind safety coaching session (a half-day stand down session for all site based personnel was held half way through the scheme).

- Implementation of high specification PPE.

(left) Treatment at source plant and (right) Inlet PS OCU – Courtesy of Morgan Sindall Sweco JV

A successful outcome

Yorkshire Water’s decision to do things differently using an innovative collaborative approach, brought together a diverse team of expertise resulting in the successful outcome of a technically challenging scheme, on programme, exceeding all expectations:

- £18m of investment delivered in 9 months.

- There have been no odour complaints associated with the process.

- Robust plant operation and performance with continued effluent compliance.

- A 20% reduction in overall site power consumption.

This way of working is undergoing a thorough post project review, the outcome of which will inform ways of working for the remainder of AMP6 and into AMP7.