Stockton Lane, York, Mains Rehabilitation (2024)

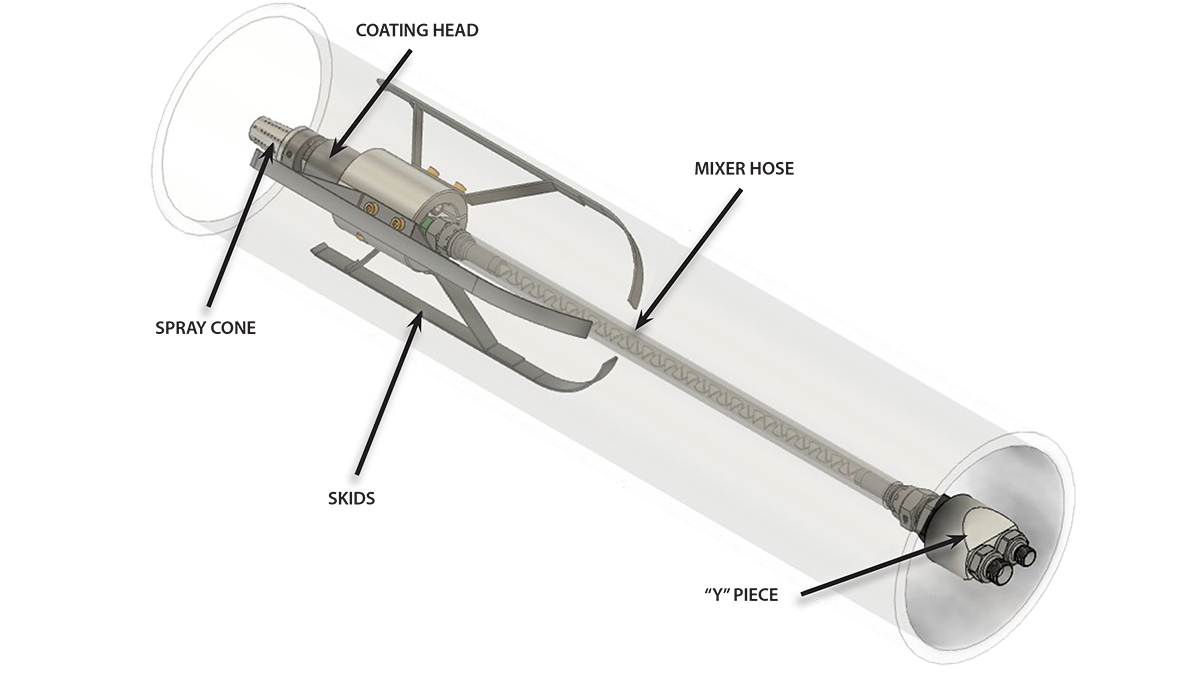

Lining head - Courtesy of Yorkshire Water

Stockton Lane is located in the north-east area of York and the water supply zone for this area is made up of approximately 21km of water main; 80% of which is metallic and 20% is plastic. Over the last 3 years Yorkshire Water have seen an increase in mains failure due to the ageing infrastructure and the supply zone is ranked in the top 5 areas for proactive capital works. As part of the utilities’ drive to proactively improve the network in Year 4 of AMP7, Yorkshire Water started investigating its options to improve its position on mains repairs, reduce leakage and customer contacts.

Undertakings

Yorkshire Water instructed Morrison Water Services to look at delivery options to maximise performance benefits as well as delivering best value for money for customers. After carrying out hydraulic modelling, mains sample tests and site surveys, the proposed delivery plan was to target the mains in the worst condition by lining 6,090m of water main utilising a lining rig from SCHUR-BPH Ltd.

Lining product selection

Yorkshire Water have been lining water pipes on its network since the 1960s; originally using cement mortal liners and more recently (from 2006) using polymeric spray liners. For Stockton Lane, Resiline 320, a third-generation aliphatic poly-isocyanate material of the same family of in situ lining products, was used. It is one of only a few DWI Regulation 31 approved lining materials in the UK. Some of the benefits it brings are:

- It is moisture tolerant.

- It can be applied from 1mm to 9mm in passes of up to 3mm for non or semi-structural lining.

- It has a low exotherm, which means it avoids shrinkage during product curing.

- It offers long term tensile and flexural creep rupture strengths.

- It enables reduced thickness linings to provide enhanced long-term performance (at least 50 years).

SCHUR-BPH lining rig – Courtesy of Yorkshire water

The lining process

To start the lining process, excavations pits are created to ensure that there are locations for the cleaning process and for the lining head to be inserted into the main to carry out the lining. The cleaning process starts by isolating the water main at two valves and using a hydrant to drain the water main. Once the water main is drained, the Whirlwind is used.

The Whirlwind cleans the main by blowing down swabs, vortexes of air, and stones, that will scratch off any excess materials and dry the pipe; ensuring that the pipe is in a suitable condition to begin the lining process. The condition of the cleaning is checked by carrying out CCTV surveys on the main. The material is applied by using a lining rig from SCHUR-BPH Ltd.

The rig comprises two paint drums that hold the base and activator paints, which are pumped and heated to the optimum temperature required (300 Celsius) to apply the material onto the pipe. A hose situated at the front of the rig holds the base and activator tubes, and this is pulled through the pipe allowing the lining material to be sprayed onto the pipe interior.

The rig uses a computer system to ensure that each specific water main is lined to the required thickness – for the Stockton Lane Rehabilitation Project, the paint application setting is 3mm due to the works being semi-structural. As well as monitoring the paint thickness, the rig also monitors the flow rate of the lining application and the temperature. If any of these factors drop below the thresholds of + or – 5% of the thickness, an alarm will raise, and the rig will shut off as the application of the material will not be to the required standards.

(left) Ling rig in operation, (top right) cleaning and (bottom right) spray lining – Courtesy of Yorkshire Water

Stockton Road, York, Water Mains Rehabilitation: Supply chain

- Client: Yorkshire Water

- Main designer/contractor: Morrison Water Services

- Lining rig: SCHUR-BPH Ltd

- Resiline 320 pipeline coating: Resimac Ltd

Resiline 320 lining material

The lining material is made up of two paints; the base and activator, which are combined to make the Resiline 320 material. The paint is mixed by using a lining head that spins at 9000 rpm and applies it onto the pipework.

To ensure that the paint is mixed correctly, the operatives take dip cards. This is a visual check to ensure that the paint is of the correct blue colour and is not brittle, meaning that is it suitable for lining. Once these checks have been completed, the lining head will be guided into the pipe, and it will be electronically pulled through by the lining rig.

The distance that can be lined per day depends on the size of the main. On the Stockton Lane project, approximately 90m of the 3” mains were lined per day; and up 110m of the 4” pipe.

Once the lining head has exited the pipe, cap ends are reapplied and a curing period of an hour is undertaken. After 15 minutes, the water mains can be inspected via CCTV. These checks are carried out are to ensure that the lining is uniform, there have been no misses over joints, fittings etc, and that there is no unmixed material as this would result in the lined section having to be replaced. Once approved by the client and the hour cure time has passed, the water main will be put back into commission and water quality samples will be taken.

On Stockton Lane, all of the above processes were undertaken on a daily basis. As part of the DWI allowance for water mains shut off periods, all the work had to be carried out within 2 hours and 59 minutes. On a good day, the work left the site team a window of between 10-20 minutes due to the process being very vigorous. If there was a risk of the time-frames not being met, decisions were made early enough to ensure that customers are not affected.

Lining head in pipe – Courtesy of Yorkshire water

Benefits of lining

Compared to replacing the water mains, the relining option realises cost, carbon and programme savings:

- The average price for the lining option is £175/m whereas traditional methods, such as open cut, average £350/m.

- For carbon, the project at Stockton Lane saved 40% compared with traditional methods (as per the carbon calculator used by Yorkshire Water).

- Stockton Lane is a highly populated residential area and the relining method leads to reduced customer disruption/complaints. The contractor was able to reline 450-500m per week, as opposed to taking 3 weeks for the same distance of mains replacement using open cut methods.

Conclusions

The project has received a great deal of attention by a Designer Liner Group that is looking to create their own lining material, and Yorkshire Water and Morrison Water Services have facilitated site visits for the members of the group. There have been minimal customer complaints throughout the duration of the project and instead, there has been a lot positive feedback on social media outlining the great work that has been carried out on a daily basis.

The Stockton Lane Rehabilitation Project promotes the potential for future sustainable rejuvenation of clean water assets, and creates a method which reduces customer disruption whilst improving services that are provided by Yorkshire Water. Upon completion, Yorkshire Water will move onto the next phase in the series of three that are being delivered as part of the Year 4 AMP7 Improvement Project.