Stroud Sewerage Strategy Project: Part 2 (2023)

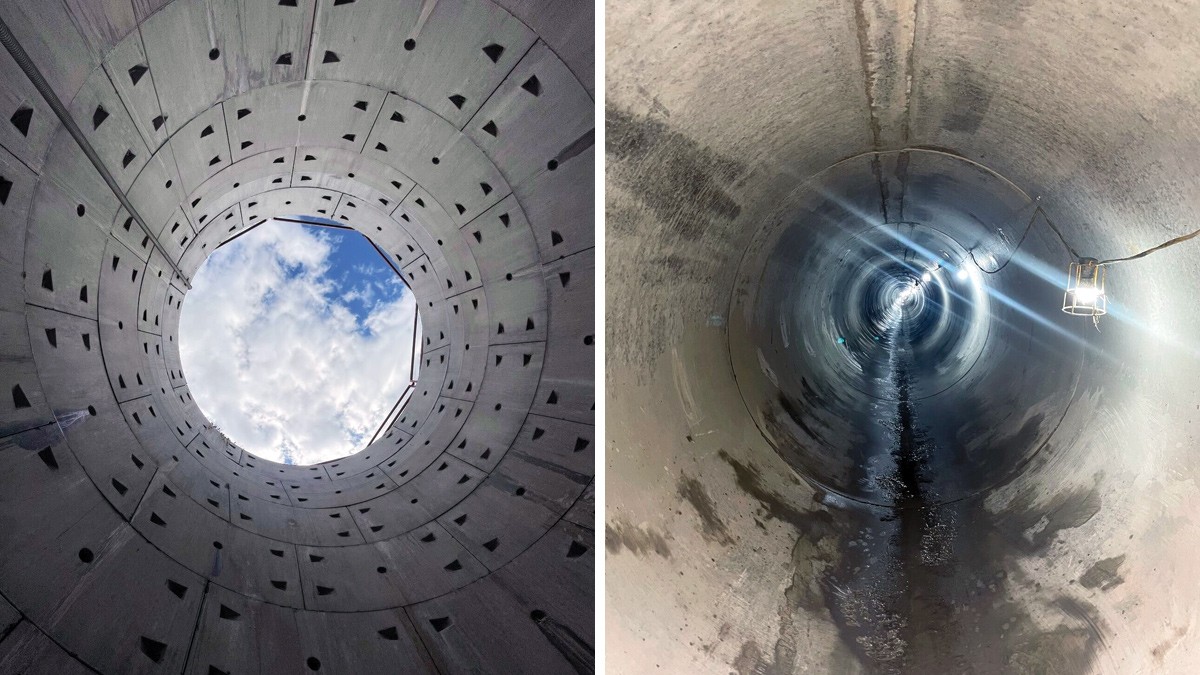

(left) Looking up out of a jacking shaft and (right) tunnelled section - Courtesy of Galliford Try

The Stroud Sewerage Strategy is a major investment by Severn Trent which is required to overhaul of the existing sewer network by installing almost 3.5km of enlarged sewer pipe, separating surface water from the sewage network, creating additional storage with smart controls to hold stormwater back during large storm events before returning it to the treatment works when the rainfall has subsided, and making improvements to Stanley Downton Sewage Treatment Works. This paper follows on from the case study published in Water Projects 2022, which focussed on the design and optioneering elements of the programme of works.

Scope of works

The Stroud Sewerage Strategy is made up of five key elements:

- Trunk sewer improvements.

- Combined sewer overflow & storage.

- Surface water separation.

- Infiltration reduction.

- Stanley Downton WwTW.

Construction started in March 2022 and details of the progress to date (July 2023) is covered in this case study.

New trunk sewer

In order to reduce the risk of sewer flooding and convey flows from the existing Wallbridge CSO, design and build contractor Galliford Try was required to design and build a second trunk sewer system, transferring flows 3.65km to the new CSO site on the outskirts of Stroud. The new sewer network will operate entirely under gravity, with no siphons and falls at a minimum gradient of 1:500.

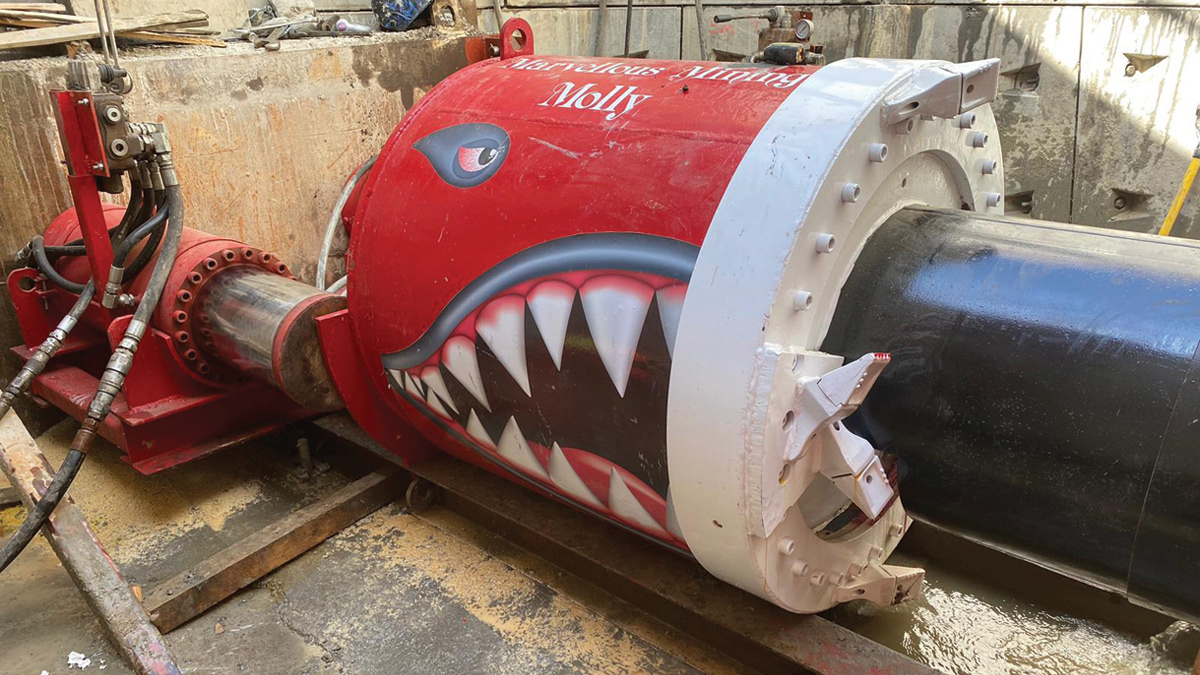

(left) The launch of TBM Marvellous Mining Molly and (right) shaft with pipe jacks installed about to be benched – Courtesy of Galliford Try

Due to varying local topography and numerous obstacles along the route the team opted for a combination of open cut and pipe jack tunnelling techniques for the trunk sewer – details below.

| Pipe diameter : Length | Details |

| 750mm = 900m | Open cut works: 2-5m deep, includes 1 x River Frome crossing |

| 1500mm = 769m | Open cut works: 3-6m deep, includes 1 x River Frome crossing |

| 900mm = 35m | TBM Marvellous Mining Molly: 1 x tunnel drive crossing under A419 |

| 1200mm = 550m | TBM Lilian: 4 x tunnel drives under Dudbrige Road (dual carriageway), car parks and private land |

| 1200mm = 650m | TBM Suzanne: 6 x tunnel drives under Stroudwater Navigation Canal & major gas mains |

| 1500mm = 591m | TBM Florence: 3 x tunnel drives under A419, Stroudwater Navigation Canal & Painswick Stream |

BSP Consulting Ltd carried out the structural design of all 12 tunnelling shafts (varying from 3.66m, 5m and 6m in diameter), with the ring segments and cover slabs supplied by Macrete (Ireland) Ltd. BSP also undertook the design calculations and documentation required for the five tunnelled highway crossings consents (CD622) and the buried service damage assessment reports for eight key service crossings along the route (the pipeline analysis was undertaken using Oasys software).

Active Tunnelling Ltd developed a bespoke tunnel boring machine setup for the 900mm micro-tunnel which involved installing an initial 600mm laser guided auger followed by a forward reaming TBM head into the auger screw. This setup avoided the need to install a 1200mm pipe which would have caused additional risk to an existing underpass in close proximity.

TBM Marvellous Mining Molly in position to start mining – Courtesy of Galliford Try

Stroud Sewerage Strategy: Supply chain – key participants

- Client: Severn Trent

- Design & build contractor: Galliford Try

- Hydraulic model: Richard Allitt Associates

- Principal ecologists: RammSanderson Ecology Ltd

- River & spillway reinstatement: Salix River and Wetland Services

- Silt mitigation: Frog Environmental

- Water vole licensing: Wildwood Ecology

- Land & planning Agents: Dalcour Maclaren

- Topographical Surveys: Geomap Ltd

- Ground investigation: Grange Geo Consulting

- Hydraulic model: Innovyze (Infoworks ICM)

- Physical model: Framatome BHR Group

- Shafts & pipejacking: Active Tunnelling

- Tunnel design: BSP Consulting

- Traffic management: Amberon Ltd

- Remediation & asbestos management: Churngold Construction

- Water main diversions: Heartland Pipelines

- Sewer lining: Colus Ltd

- Temporary PortaDams: OnSite Central

- Steel fabrication & penstocks: GT Fabrications

- Open cut pipework: LCS Groundworks Ltd

- Open cut pipes: Marshalls CPM

- Electrical installation & MCC: Cema Ltd

- DI pipework: Electrosteel Castings (UK) Ltd

- Shaft rings & cover slabs: Macrete (Ireland) Ltd

- Jacking pipes: FP McCann Ltd

- Washwater pumps: KGN Pillinger

- Lifting equipment: T Allen Engineering Services

- Submersible pumps: Xylem Water Solutions

- CSO screens: Longwood Engineering Co Ltd

- Prefabricated chambers & backdrops: Polypipe Civils & Green Urbanisation

- Access covers: Steelway Brickhouse

- Manhole covers: Saint Gobain PAM UK

- Fencing & tree clearance: Landscape Maintenance Services

Interception chamber

Galliford Try was required to design a new interception chamber to convey all the flows of the existing Nailsworth Sewer into the new network. Working on a live network and dealing with large flow rates naturally led the team to design a prefabricated chamber to minimise the installation time. Designers from Galliford Try and Polypipe Civils & Green Urbanisation developed a solution that incorporated a permanent backdrop, temporary flume pipe and four connections (750mm, 750mm, 1200mm and 1500mm in diameter). It was built off-site in three sections and assembled on site in one day.

(left) Installation of prefabricated chamber within live sewer line and (right) inside the prefabricated chamber – Courtesy of Galliford Try

River Frome crossings

Due to the need to retain a constant gradient, both sewer crossings under the River Frome were very shallow with very little cover to the erodible bed level. Without creating syphons, open cutting through the river was the only feasible solution. A temporary bypass channel was constructed and lined using Salix River and Wetland Services coca matting and Frog Environmental rock rolls to prevent mobilising sediment during the works.

Temporary PortaDams from OnSite Central Ltd were installed to isolate a section of river. RammSanderson Ecology Ltd provided ecological support, including moving 1554 fish between dams (129 brown trout, 493 brook lamprey, 715 bullheads, 209 sticklebacks, five eels and three roach). This element of work required a huge amount of planning and permits from Galliford Try’s Environmental Team, the Environment Agency and Natural England.

Construction of bypass channel and (inset) installation of the temporay PortaDam from OnSite Central Ltd – Courtesy of Galliford Try

New CSO shaft

Construction of the new 25m diameter, 28m deep combined sewer overlflow shaft started in summer 2023.

A detailed update will be published on WaterProjectsOnline.com later in the year.

Surface water separation

The 3.88 hectares of impermeable surface area being separated from the existing catchment is situated in Stroud town centre and involved designing a new 555m long, 300mm diameter, intricate surface water sewer network within the constraints of a densely built-up area to intercept flows which otherwise would have ended up in the combined network and added to the spill events in the downstream catchment.

Galliford Try undertook GPR surveys and numerous trial holes to create a map of existing buried assets and plan a route for the new sewer network. To reduce service diversions to a minimum, a number of bespoke manholes were designed, and the Galliford Try team proposed relining the existing foul sewer rather than replacing it which considerably reduced disruption and construction timescales on site.

Flows from the newly separated network are transferred to Stroudwater Canal via a 232m long connection across a supermarket and council car park and under an existing retaining wall. Due to the interface with the general public and potential upheaval of working in car parks, Galliford Try chose to install the 600mm diameter pipes by using a laser guided auger. In conjunction with specialist Active Tunnelling Ltd, drive and reception pits were carefully positioned within car parking bays and the route designed to minimise disruption as far as practicable. On completion of the works, all affected stakeholders were positive and complimentary over the tidiness of the work sites.

(left) Excavation of shaft and (right) preparations for open cut rising main installation – Courtesy of Galliford Try

Infiltration reduction

To free up capacity for foul flows in the existing network, Galliford Try eliminated 3 l/s of infiltration with specialist Colus Ltd by installing 475m of liners and injecting two-part polyurethane sealant at key locations. The constant groundwater flow was caused through a combination of old cracked sewers, old brick manholes with blown mortar and badly made connections onto the existing network.

Conclusion

At the time of writing (July 2023), the last remaining parts of the project include modifications to the storm return pipework at Stanely Downton WwTW, and the demolition of the existing Wallbridge CSO site. These works will be undertaken upon completion and commissioning of the new assets.

The whole team from engineers, design, procurement, commercial and project management working on this difficult project have pulled together to overcome numerous unforeseen physical, environmental, financial and stakeholder challenges in Stroud. The author wishes to credit everyone involved; sub-contractors, supply chain and the client for achieving what has been delivered to date.

Bypass channel in use - Courtesy of Galliford Try