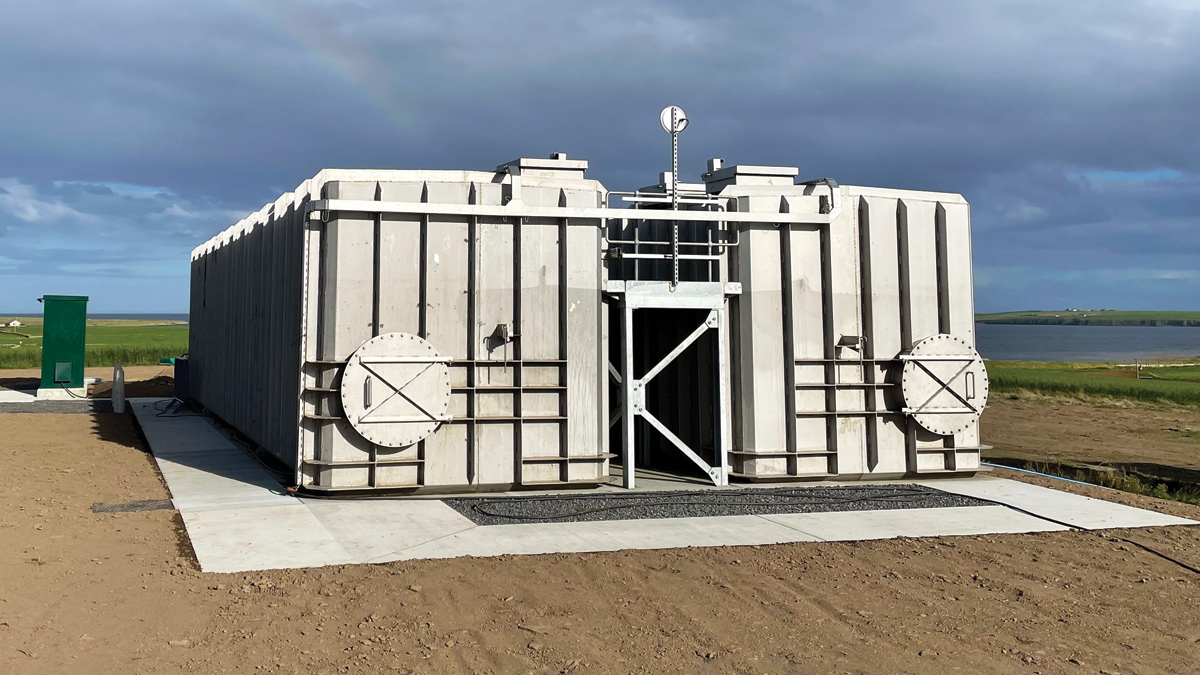

Whitehall Distribution Service Reservoir (2023)

Whitehall DSR at Stronsay WTW, Orkney Islands - Courtesy of ESD

Whitehall Distribution Service Reservoir (DSR) is located on Stronsay, one of the north isles in Orkney, located 25 miles to the north of the Orkney mainland. The isle is home to 350 residents and is accessible by public ferry and plane. The Stronsay WTW that feeds the DSR is 300m to the south of the tank location. The WTW had a new TTU installed in 2021, giving a cutting-edge membrane solution to mitigate cryptosporidium failures in the local network. The new DSR replaces a 75 year-old concrete structure that had potential water quality failure zones highlighted in the project intervention report. The existing works serve the residents of Stronsay with gravity and pump fed supplies out of the 300m3 storage facility at Whitehall.

Material selection

The initial intervention received from Scottish Water included provision for a new in situ concrete twin cell clear water tank (CWT). In light of the challenges listed within the bullet points below, the project team proposed to review alternative materials of construction to overcome some of these risks/challenges:

- Single ferry to island each day.

- Restrictions around local quarries opening times and ferry times.

- No access on ferry for HGVs.

- Risks around workers’ and delivery drivers’ working hours and ferry times.

- The 2.5 hour ferry journey incompatible with ready-mix concrete deliveries.

- Carbon footprint excessive.

On review, a table of comparisons was presented with alternative materials listed below.

- Precast concrete.

- Glass coated steel.

- Large diameter ground pipe.

- Stainless steel.

A joint review by the client, Scottish Water, and delivery partner, ESD (a joint venture between Binnies, MWH Treatment and Galliford Try), concluded that the stainless steel option presented best value all round and was accepted as the preferred solution.

The project team commenced work on finding Drinking Water Inspectorate (DWI) approved suppliers of stainless steel tanks, as well as working through the challenges of design and delivery of this solution.

Ocean Kinetics Ltd (a local contractor that had worked alongside ESD and Scottish Water designing and building small scale stainless steel rapid gravity filters for a project on Shetland), was selected due to their design, manufacture and installation capabilities.

Ocean Kinetics Ltd supplied a DWI approved factory environment for stainless steel manufacture and completed the full structural design, manufacture and installation of the tanks.

Manufacturing the tanks off-site – Courtesy of ESD

Whitehall DSR: Supply chain – key participants

- Client: Scottish Water

- Principal designer & contractor: ESD JV

- Design, fabrication & installation of stainless steel clear water tanks: Ocean Kinetics Ltd

- MCC/systems integration: Ross-shire Engineering

- Civil engineering contractor: Heddle Construction Ltd

- Mechanical installation contractor: Ocean Kinetics Ltd

- Electrical installation contractor: RS Merriman Ltd

- Access metalwork: Ocean Kinetics Ltd

DfMA & collaborative design

The strategy from the outset of the project was to maximise the use of Design for Manufacturing & Assembly (DfMA) and the use of the available digital delivery tools, with the primary aims being:

- Reduced Programme: CWT construction to be completed in factory environment, reducing the amount of person hours on-site while also enabling fabrication to be conducted concurrently with civil construction.

- Improved quality: Stringent quality control in fabrication facilities.

- Reduced HSE Risk: Due to the factory construction of the CWTs, a significant portion of the construction is completed in a controlled factory environment, rather than on site.

The site manager for the project, Gregor Matheson, felt that there was further opportunity with this solution to mitigate site risk, mainly around contamination suite sampling of the CWTs. This process in a site can often provide frustration with delays of water into supply common.

The Scottish Water public health team was contacted and asked if there was a mechanism that would allow the sampling of the water quality in the new stainless steel tanks to be taken while still in the factory. The response from the PHT was positive and it was agreed that upon completion of all welding, the tanks were flushed as they would be on site, in line with SW procedure, then contamination suite testing could commence.

Delivery to site – Courtesy of ESD

Status – June 2023

The new Whitehall Distribution Service Reservoir is now in operation with water into supply achieved in only 84 site days. Each cell was fabricated with lifting hooks that enabled crane installation, which also serves as an end of life advantage where a replacement tank can be fabricated, taken to site, the existing tank removed, and the new tank installed; a 2-day operation on site mitigating the need for new land to be purchased and new tank construction etc.