Witches Oak WTW: Green Recovery – Decarbonising Water Resources (2025)

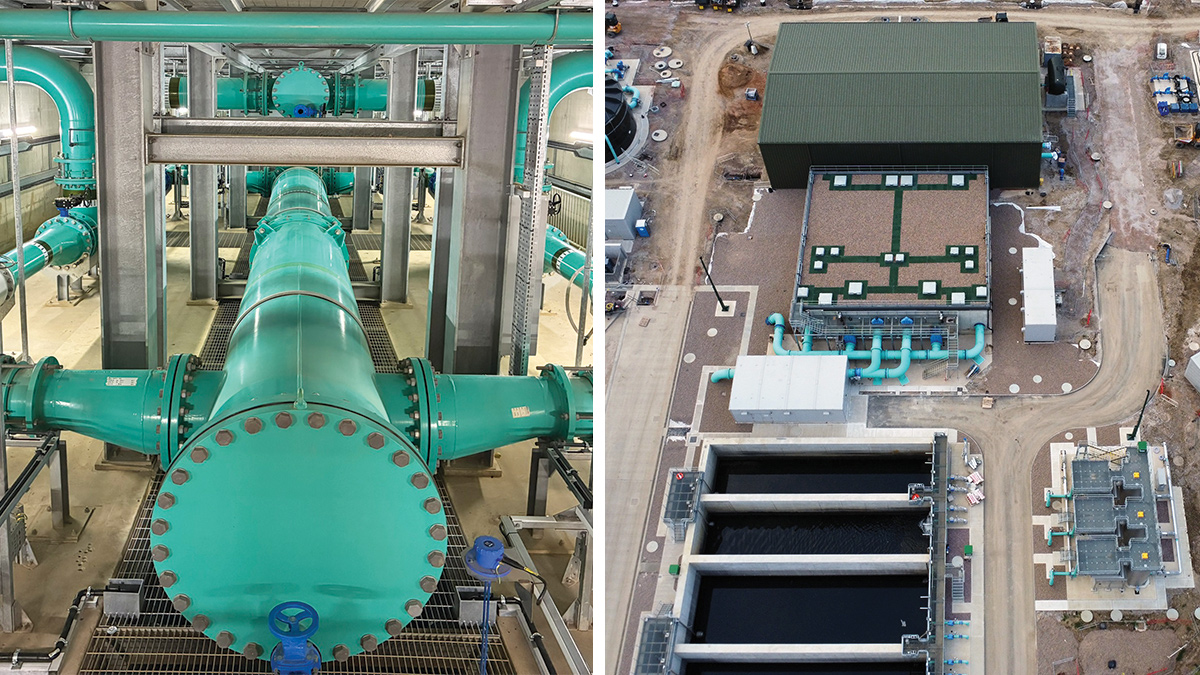

Site overview (August 2025) - Courtesy of MWH Treatment

In the summer of 2020, the water industry was set a challenge by its regulators to identify ways to support the country’s green economic recovery from Covid-19. Severn Trent responded with several proposed programmes, including Decarbonising Water Resources (DWR). The objective of the DWR Programme is to provide additional treated water to Severn Trent’s water network in a low-carbon, reduced-chemical treatment way. The need for this additional water is based on the supply demand balance, taking into account drought, climate change, the reduction in groundwater supplies and the need for more resilient water supplies. In 2020, Severn Trent secured the abstraction license for the River Trent from the decommissioned Rugeley power station. This license was for a peak abstraction of 93Ml/d and was appended by the Environment Agency to the Severn Trent existing site at Witches Oak.

Raw Water Project

The Raw Water Project required refurbishing the existing River Trent abstraction inlet, pumping station, and 1000mm rising main and associated equipment. The scope included the addition of three new pumps, electrical systems and an associated fish and eel recovery system to enable raw water to be abstracted from Witches Oak Waters and supplied to the new Witches Oak WTW.

Witches Oak Hydrolox intake eel screens – Courtesy of Severn Trent

The Raw Water Project also includes the first stage of treatment using innovative floating treatment wetlands (FTW) as biological pre-treatment to reduce the turbidity, phosphates, ammonia, and nitrates in the raw water ahead of transfer to the new WTW.

Mott MacDonald Bentley and Biomatrix were engaged to first install three FTWs as an early install opportunity in November 2022, with the remaining 28 successfully installed in the summer of 2023. Close collaboration between the design team, site managers, and environmental specialists to produce a series of bespoke management plans was paramount to protect the high ecological value of the site during the construction of the wetlands and the removal of a redundant man-made wetland from the lake.

Treated Water Project

The new Witches Oak Water Treatment Works has been designed to provide a minimum resilience (also taken as the average) flow of 65Ml/d as deployable output.

The new works has been constructed in record time and at the time of writing (July 2025), all MEICA equipment has been installed. The plant is being commissioned with reliability trials, process optimisation, and performance tests to achieve water into supply in 2025.

Raw water balance tanks – Courtesy of MWH Treatment

Raw water operational flexibility

Raw water balance tanks have been constructed to blend River Trent and Derwent flows and improve the hydraulic control into the new water treatment works. The River Trent poses many water quality challenges for conventional treatment, with difficult to treat organics (high concentrations of both hydrophilic and hydrophobic), elevated levels of both nitrate and ammonia. While the plant’s ceramic membranes are designed to treat River Trent water, it can also treat raw water from the River Derwent at a reduced operational cost.

Bedford Pumps was selected for the Derwent boosters due to high efficiency, low noise and space saving design. Three DWI-compliant SB40.16.06 in-line dry well mixed flow suspended bowl pumps complete with 72kW motors coupled to ABB variable speed drives give the flow range in duty/assist/standby configuration.

Two auto-backwashing 6.18 GR600 Bollfilters® with 1mm stainless steel wedge wire candle elements from Bollfilter UK Ltd are installed with backwash pumps to remove any debris. They are installed with an access platform and overhead gantry to allow annual stripping down for deep cleaning and maintenance.

Bollfilter strainers – Courtesy of MWH Treatment

Inline coagulation (ILCA®)

The flow is pH corrected with sulphuric acid via a static mixer then dosed with polyaluminium chloride (PACL) into the In-Line Coagulation and Adsorption (ILCA®) inlet weir with a hinged sparge pipe which can be lifted for cleaning and maintenance. PWNT’s ILCA® process was developed to minimise coagulation/flocculation footprint upstream of CeraMac®.

For surface waters, coagulated feed water lowers the ceramic membrane fouling rate, but strong, large, setting flocs are not required for microfiltration so ILCA® provides the necessary mixing with no moving parts and a short contact time.

Witches Oak WTW: Supply chain: Consultants & Contractors – key participants

- Principal contractor & designer: MWH Treatment Ltd

- Distribution designer: Mott MacDonald

- Biodiversity designer: ARUP

- PFAS treatment pilot plants specialist process engineering designers: WISP Global Ltd

- Hydraulic modelling: Stantec UK

- Wetlands designer/contractor: Biomatrix Water

- Hydrology surveys: LDE

- O&M manuals: Cognica

- Process engineering: MWH Treatment Ltd

- Process engineering: PWNT

- Process engineering: Nijhuis

- Process engineering: Nortech

- Raw water PS & wetlands: Mott MacDonald Bentley

- Physical hydraulic modelling: Hydrotec Consultants Ltd

- ILCA® & CeraMac design & installation package: Nijhuis H2O UK Limited | Waste Water Solutions Ltd

ILCA® coagulation tanks – Courtesy of MWH Treatment

- Earthworks: Naylor Plant & Excavations

- Earthworks: JC Balls & Sons

- Temporary works/shoring: MGF Ltd

- Temporary works/shoring: National Trench Safety UK

- Piling: Balfour Beatty Ground Engineering

- FRC works main structures: STAM Construction Ltd

- Strainer RC slab, pipework & HV ducting: ATB Civil Engineering Ltd

- Underground pipework & services: Arthur Civil Engineering

- Underground pipework & road crossings: M2 Civils Ltd

- Underground pipework: RTN Civils Ltd

- DVA connection: Barhale

- Ceramac building: Severfield Nuclear & Infrastructure Ltd

- GAC building: AJ Engineering & Construction Services Ltd

- Electrical installation: Southern & Redfern Industrial Solutions Ltd

- HV switchgear & cabling: Central Power Services

- Mechanical installation/pipework: Powerrun Pipe-Mech Ltd

- Mechanical installation/pipework: Fluid Sealing & Engineering Ltd

- Substation construction: Hollywood Civil Engineering

- ILCA® cofferdam & excavation: CR Civil Engineering

Membrane air spring vessels, chemical dosing kiosks and safety shower – Courtesy of MWH Treatment

CeraMac® membrane process

CeraMac® is an innovative ceramic membrane microfiltration process designed by PWNT for large-scale surface water applications featuring multiple membranes in a single vessel to make it cost-effective.

The advantages of ceramic membranes include:

- No fibre breakage ensures high reliability.

- Indefinite life span (proven to be >20 years in continuous usage.

- Use of chemicals to clean the membrane and prevent fouling.

- High backwash rates at 5 bar to restore permeability.

- Narrow 0.1 micron pore size distribution.

- Absolute barrier.

- Sustainable materials.

- High throughput with compact footprint.

The membranes are manufactured by Metawater (NGK) of Japan. This process will serve as the filtration barrier and is credited with 4.0 log cryptosporidium, 4.0 log giardia, and 1.0 log virus removal.

The CeraMac® membrane process consists of:

- 14 (No.) C90 vessels.

- 14 (No.) back wash vessels.

- Air spring vessels.

- Stainless steel pipe work.

- Fast acting butterfly valves.

- Feed pumps.

- Air and instrument compressors.

- Actuated valves.

- Mechanical valves.

- Pressure, level and flow instrumentation installed on a galvanised steel mezzanine platform with two levels.

CeraMac C90 membrane vessels – Courtesy of Severn Trent

Nijhuis Saur Industries and Wastewater Solutions Ltd were subcontracted as technology partners for the extended scope package responsible for the design, manufacture, installation and commissioning of the complete system. Dixon Engineering Ltd manufactured and installed the steelwork, and March Engineering provided the stainless steel pipework.

The membranes will be backwashed automatically based on the flux rate with filtrate and periodically chemically enhanced backwash (CEBW) with sodium hypochlorite, sodium bisulphate and hydrogen peroxide to control fouling. Clean-in-place (CIPs) will be performed as required. The chemical containing waste is neutralised prior to disposal to the process waste tank which pumps to the sewer.

Derwent pilot trials were used to optimise the backwashing configuration to:

- 14 normal backwash (membrane filtrate).

- 1 acidic enhanced backwash (target pH2) – metals removal (15-20 minutes duration).

- 14 normal backwash (membrane filtrate).

- 1 hypochlorite enhanced backwash (target 100 mg/l of free chlorine) – bacterial removal.

- CIP interval will be >14 days – (on the pilot plant CIP every 3-4 months of operation).

C90 membranes in pressure decay test – Courtesy of MWH Treatment

The PWNT scheduler is proprietary software which manages and optimises the complex backwash operations using model predictive control methods.

The CeraMac® process has a dedicated motor control centre (MCC) and local control panels (LCP). The electrical manufacture and installation was by BGEN including system integration software. SCADA was configured by Ovarro.

Witches Oak WTW: Supply chain: Process Plant & Equipment – key participants

- Eel screens: Hydrolox

- Raw water balance tanks: Stortec Engineering Ltd

- Raw water autostrainer: Bollfilter UK Ltd

- Clean backwash tanks: Hayes GFS Ltd

- UV reactors: Trojan Technologies

- Ceramic membranes & CeraMac vessels: Nijhuis PWNT

- CeraMac steelwork: Dixon Engineering Ltd

- Pipework & vortex breaker: Alpha Plus Ltd

- Wall starters & pipework: Freeflow Pipesystems

- Membrane stainless pipework: Musk Process Services

- Membrane stainless pipework: Hi-Tech Fabrication Ltd

- Membrane stainless pipework: Franklyn Yates Engineering

- Ductile iron pipework & Ve joints: Saint Gobain PAM UK

- Submersible pumps & mixers: Xylem Water Solutions

- High lift & backwash pumps: SPP Pumps Ltd

- Variable speed drives: ABB Ltd

- Air scour blowers: AERZEN Machines

- Derwent booster pumps: Bedford Pumps

- Valves: AFFCO Flow Control (UK) Ltd

- Valves: AVK UK Ltd

- Valves: Cotswold Valves Ltd

- Lamella thickeners: Jacopa

- Chemical storage & dosing: IIES (Northern) Ltd

- Chemical dosing tanks: Forbes Technologies

- Safety showers: Aqua Safety Showers International Ltd

- Polymer dosing system: Richard Alan Engineering

- Surge vessel: Quantum Engineering Developments Ltd

- Flow meters: Siemens

(left) GAC pipework gallery ground floor and (right) dirty backwash and treated water tanks – Courtesy of MWH Treatment

- Instrumentation (pH, turbidity, nitrate & UV): Endress+Hauser Group

- Instrumentation (chlorine): Badger Meter

- Instrumentation (flow monitoring): IFM Electronics

- Instrumentation (flow monitoring): Georg Fischer

- Instrumentation (Aquascat Turbidity monitoring): Sigrist Photometer

- Sample pumps: Grundfos Pumps Ltd

- Static mixers: Statiflo International

- GRP kiosks: Morgan Marine

- Process plant MCCs: CEMA Ltd

- Membrane MCC & instrument backboards: BGEN Ltd

- SCADA configuration: Ovarro

- Transformers: Wilson Power Solutions Ltd

- HV switchgear: BRUSH

- Ring main units: Schneider Electric

- Strainer & MCC steelwork: GT Fabrications

- Filter floor nozzle panels: Cadar Ltd

- Installation of filter floor panels: Filtec Water Services

- GAC media: Chemviron

- GAC access & MCC support steelwork: Tushingham Steel Fabricators Ltd

- Gantry cranes: Konecranes Demag UK Ltd

- Lifting equipment & testing: T Allen Engineering Services Ltd

- Ventilation systems: Air Technology Systems

- Security fencing: Binns Fencing Ltd

- Administration building: Integra Buildings

GAC filtration proven template design

Filtered water is pH corrected with sodium hydroxide and dosed with sodium hypochlorite to oxidise iron and manganese as well as providing breakpoint chlorination for ammonia destruction. The filtered water and chemicals are mixed with a static mixer with controlling sample instruments downstream.

The dosed filtered water is distributed between eight granular activated carbon (GAC) contactors for removal of organic compounds, pesticides, taste and odour, and precipitated iron and manganese. The GACs are periodically backwashed to remove solids, anaerobically conditioned to kill chironomids and regenerated to restore efficacy. The washings are normally directed back to the reservoir but can also be diverted to the dirty backwash tank.

Lamella settlement tanks to treat backwash water – Courtesy of MWH Treatment

Eight GAC filters have been loaded with Chemviron Carbsorb® 40plus media (216.75m3 per cell) which has a high hardness ensuring excellent resistance to abrasion caused by transport and backwashing. A permanent 100mm pipework system is provided for tanker connection to allow media filling and removal for reactivation.

The two GAC backwash pumps (duty/standby) are Aquastream end suction AM40A horizontal variable speed drive pumpsets from SPP Pumps Ltd, complete with ABB 132kw motors. Two Delta G5 air scour blowers from AERZEN Machines provide volumetric flowrate of 2,890m3/hr at 0.55bar.

Primary disinfection with UV

The two TrojanUVFlex® 100 reactors from Trojan Technologies allow for energy-efficient high-intensity delivery of UV light in a compact footprint, with simple operation. The UV lamps are arranged in arrays perpendicular to the flow, in quartz protective sleeves to reduce operating costs by allowing independent sections of lamps to be turned on/off in response to changing water quality and ensures continuous treatment by downstream lamps in the event an upstream lamp failure.

A smart control system with UV intensity sensors and UVT monitors automatically optimises energy use while ensuring UV dose and treatment compliance to inactivate micro-organisms such as giardia and cryptosporidium. Each reactor has 900mm diameter flanged connections, 128 (No.) 500W amalgam lamps, temperature switch, dose control system, automatic wiping system, control and power panel (compliant with Severn Trent specifications), Trojan OIT 7” Display LCP HMI, hydraulic system centre. Design UV transmittance (1 cm) min. 85%, UV dose min. 95 mJ/cm2 validated dose.

TrojanUVFlex® 100 UV reactor – Courtesy of MWH Treatment

Twin compartment treated water tank

Treated water is dosed with orthophosphoric acid for plumbosolvency and sodium hypochlorite and mixed with a static mixer prior to flowing through contact mains. Sodium bisulphite and sodium hydroxide are dosed to control the residual chlorine level and pH respectively prior to entering the new treated water pumping station and then into supply. Out of specification treated water is directed to the emergency return pumping station (ERPS). The flow is dosed with sodium bisulphite to ensure chlorine levels are within acceptable limits.

Emergency return pump station (ERPS)

The ERPS has been invaluable for the commissioning phase as it has allowed the raw water flows to be recirculated back to the adjacent Church Wilne Raw Water Reservoir to test the new process assets and prove reliability prior to water into supply (WIS)1.

Three submersible pumps (duty/assist/standby) each rated for 358l/s at 15.6m head from Xylem Water Solutions are installed with 125kw motors.

1 Church Wilne Raw Water Reservoir is adjacent to Witches Oak WTW and supplies Church Wilne WTW. The supernatant from the new Witches Oak WTW is supplied to Church Wilne Raw Water Reservoir rather than returned to the head of the works at Witches Oak WTW due to pilot trials showing the polymer in the water had the potential to irrevocably blind the membranes.

High lift pump station with surge protection to supply DVA

The four high lift pumps for potable water (duty/assist/assist/standby) split case, BT10DL horizontal variable speed drive pumpsets from SPP Ltd (complete with IE3 710kw 690v/3/50 4-pole motors from ABB Ltd) supply the DVA network at 15 bar.

A 22.5m3 capacity carbon steel horizontal surge vessel was designed and manufactured by Quantum Engineering Developments Ltd to PED/PD5500-2021 Category 2, suitable for a design pressure of 25 bar.

High lift pumping station – Courtesy of MWH Treatment

Multiple gangs install 1970m of DI pipework

The underground interconnecting pipework was designed to be anchored to eliminate the need for concrete thrust blocks. Saint Gobain PAM UK provided the WRAS/DWI approved ductile iron pipework up to 1200mm diameter using the UNIVERSAL Ve push-in locking joint system.

It is suitable for double chamber socket pipes with a weld bead on the Ve spigot end. This system needed to be installed by experienced specialist subcontractors, and the work was undertaken successfully by Arthur Civil Engineering, M2 Civils Ltd, ATB Civil Engineering, and RTN Civils Ltd.

Saint Gobain PAM UK’s technical support was invaluable to optimise the system based on the 3D model and accurate site measurements. Pipework was stockpiled in the local yard at Ilkeston to save space on the constrained Witches Oak compound. It was important to design and procure early as delivery is 12-16 weeks.

Reservoir return pipes – Courtesy of MWH Treatment

Water quality monitoring

The design, supply, manufacture, testing and delivery of the analyser boards required for the new water treatment works was provided by BGEN who have developed a design for Severn Trent to ensure standardisation across sites to benefit the operators.

Sampling and instrument boards were fitted at all stages of the process to ensure water quality compliance.

The following instrumentation was included:

- pH, turbidity, nitrate & UV: Endress+Hauser

- Ammonia, iron, aluminium, manganese, phosphate & nitrate analysers: ABB

- Chlorine: Analytical Technology Inc (ATi) | Badger Meter

- Flow monitoring: IFM

- Flow monitoring: Georg Fischer

- Aquascat Turbidity monitoring: Sigrist

- Sample pumps: Grundfos

PACL bulk storage tanks – Courtesy of MWH Treatment

High quality chemical dosing systems

The project team evaluated a number of systems and selected IIES (Northern) Ltd due to their high-quality designs which were competitive and achieved the delivery periods.

IIES (Northern) Ltd had the production capacity to deliver the entire dosing package to avoid multiple suppliers. The benefit of the standardised approach is that the operators will have continuity across the chemical island which will improve health and safety.

The chemical scope included bulk storage tanks and dosing for:

- 96% sulphuric acid.

- 18% PACL (as Al203).

- 15% sodium hypochlorite.

- 20% sodium bisulphite.

- 47% sodium hydroxide.

- 6% hydrogen peroxide.

- 75% orthophosphoric acid.

The nine dosing rigs were factory fitted into Morgan Marine GRP kiosks and fully tested at cFAT’s to ensure compliant and avoid defect correction on site. The high quality bulk storage tanks were manufactured by Forbes Technologies Ltd.

(left) Sodium hypochlorite dosing cabinet by IIES Northern Ltd and (right) chemical injection lances and point of application cabinets – Courtesy of MWH Treatment

The installation team worked hand in hand with the commissioning teams to test and bring the chemical dosing systems into service safely. The dosing cabinets feature lime green backboards to make the equipment easy to see for operation and maintenance.

Statiflo International supplied Series 650 motionless mixers with two STM stainless steel elements to provide chemical injection with two pairs of withdrawable lances (duty/standby). Horizontally mounted lance cabinets manufactured in polypropylene divided into twin compartments provide a safe working environment at ground level for maintenance and removal whilst in service to protect the operators.

Electrical system designed for resilience

A new National Grid substation with three feeders has been installed in a secure compound. This supplies the two Severn Trent 11kva switchboards at Witches Oak and two new feeds to Church Wilne. Wilson Power Solutions Ltd has supplied five T2 Ecotrans® distribution transformers with Ringmaster units which feed the various process MCCs, all fitted with emergency generator incomers as below:

- Raw water MCC with sampling and flow monitoring.

- Membrane MCC with 18 remote I/O (RIO) panels.

- GAC MCC and switchboard with eight RIO panels.

- UV supervisory panel and switchboard.

- HLPS MCC with 690v and 400v sections.

- Waste and returns MCC.

- LV switchboard.

- Five UPS units for critical instrument back-up.

- Ten chemical dosing rig local control panels.

A SCADA system with dedicated server and eight node panels connected on a fibre ring main allows operation and monitoring of the plant with multiple workstations in the control room and around site. A remote link allows SCADA monitoring at Church Wilne WTW.

Waste and return MCC – Courtesy of MWH Treatment

Well planned commissioning

A detailed five-stage commissioning strategy was developed early in the project which identified commissioning pipelines and valves to be incorporated into the design to facilitate process unit bypassing and flow recirculation. The Commissioning Manager holds a morning briefing to control and coordinate all the daily activities including relevant subcontractors.

Pilot plant data has been used to good effect to set initial parameters and provide seasonal variations. Reliability tests have been run in recirculation mode using the emergency returns pump station, so no raw water was wasted, and this has allowed fail-safe testing to be undertaken off-line.

An experienced team of Nijhuis PWNT commissioning engineers was responsible for testing, commissioning and optimising the ceramic membrane system and ancillary plant based on their operational expertise.

Severn Trent recruited the new Operators early to allow them time to shadow the commissioning team to gain familiarity with the new works prior to going into supply. Training workshops are provided which are a mix of classroom learning and hands-on practical demonstrations on site.

An engineering register has been set up to feedback commissioning experience to the process designers for the benefit of future schemes and compilation of as-built documentation.

PWNT specialist membrane loading team – Courtesy of MWH Treatment

Change control

The high degree of change on this contract has been carefully managed and NEC contract administered prudently by the project team. The scope has been adjusted with over 50 compensation events with £7m increase to the target price. The additional designs have been integrated, costs agreed, and assets delivered on programme which is testament to the proactive teamwork.

Awards

The Project Team was delighted to receive recognition from the following Water Industry Awards:

- Severn Trent Innovation Award 2024 for the use of Ceramic Membrane technology at WO.

- ICE East Midlands Merit Awards 2025: Project Delivery Team Highly Commended.

- RSK Efficiency & Innovation Award: Winners for Ceramic Membranes and Digital Delivery

Conclusion

A fast-track scheme of such complexity required the highest level of collaboration between stakeholders, design engineering disciplines, constructors and supply chain partners. At peak there were 192 people on site working together to the highest quality and Health & Safety standards. The programme was extremely detailed and had to be broken down into manageable look-aheads, which were reviewed weekly in collaborative planning sessions.

The site management team utilised trackers for the pipework and roads to monitor and control progress. The project engineers conducted expediting visits to the key suppliers to verify that manufacture was on schedule and to specification. Working at such a fast pace required constant problem solving, timely decision making and adaptability to maintain progress.

MWH Treatment had to employ multiple civil and MEICA installation teams to secure the required resources for concurrent working at the busiest period of the AMP, this had the added benefit of healthy competition on site. The commissioning team developed a detailed five stage plan to test and commission all the new assets and achieve water into supply. This was digitised into a 16-minute animation which helped the new operators visualise the process to understand the sequence and constraints.

To design, build, assemble and commission an entire new 90Mld water treatment plant in 2.5 years is a real achievement in which the whole team should be immensely proud.

Commissioning the raw water tanks at sunrise - Courtesy of MWH Treatment