Poolend Borehole Capital Maintenance (2021)

(left) Arisings from auger drilling and (right) reverse circulation drilling rig - Courtesy of MMB

Severn Trent’s existing Poolend Borehole Pumping Station is located near Leek in Staffordshire and is one of four sources that supply water to Ladderedge DSR. A second borehole source feeds into the Poolend site where both sources undergo water treatment (pH correction, plumbosolvency, marginal chlorination, and ultraviolet (UV)). To ensure continued water security in the Staffordshire area, Mott MacDonald Bentley (MMB) were contracted by Severn Trent to undertake the Poolend Borehole Capital Maintenance Project and construct and commission a new borehole to replace an existing asset expired borehole on the site.

Existing works and project overview

Prior to the project the site comprised of two boreholes (BH1 and BH2), operated in a duty/standby configuration. BH1 and BH2 were completed in 1934 and 1949 respectively, and therefore were towards the end of their expected generic asset life. CCTV and geophysical evidence indicated that Poolend BH1 was in need of replacement.

The project outcomes were to:

- Drill and commission a new borehole (BH3) and associated headworks to replace borehole 1.

- Install variable speed drive pumps in boreholes 2 and 3.

- Decommission and backfill borehole 1.

The installation of variable speed drive pumps allows better control of the high turbidity that is sometimes experienced during pump start up.

Slotted casing being lifted into place in BH3 – Courtesy of MMB

Drilling the borehole

The target aquifer was the Chester Formation which comprises ‘conglomerates and reddish brown, cross-bedded, pebbly sandstones with subordinate beds of red-brown mudstone’. The Chester Formation is unconfined meaning there is no impermeable layer above the aquifer.

Construction of BH3 commenced in 2018 and auger drilling techniques were used to a depth of 30m below ground level (BGL) before the installation of 30m of 914mm diameter steel casing. The steel casing was grouted in place using a grout shoe. Drilling continued to a depth of 120m using reverse circulation rotary drilling methods at a diameter of 814mm. Careful management of the drilling fluid was required during the rotary drilling operation to minimise the impact on the operational abstraction boreholes at the site. Upon completion of the drilling programme a 762mm diameter steel bridge slot casing was installed in the borehole.

Below is a summary of borehole construction and drilling techniques used:

Depth: 0 – 30m

- Diameter: 1016mm

- Casing: 914mm steel casing

- Drilling method: Auger drilling

Depth: 30 – 120m

- Diameter: 814mm

- Casing: 762 mm steel bridge slotted casing

- Drilling method: Reverse circulation

A programme of test pumping was undertaken to assess the performance of the borehole as summarised below:

- Step test; 5 (No.) 100-minute steps at increasing discharge rates, followed by a monitored recovery period until a full recovery was achieved.

- Constant rate test (CRT); 28 days of abstraction at a constant rate.

The step test is used to assess the efficiency of the borehole. The constant rate test is used to measure aquifer properties, gather data on water quality and assess the impact of the borehole on the wider environment including other water users. Water samples were collected throughout the test pumping and bulk water chemistry parameters were monitored continuously. Given the limited drawdown observed over the course of the CRT (<10m), even whilst abstraction continued from the existing operational boreholes, it was considered that BH3 was capable of providing the yield required by Severn Trent and was therefore suitable as a replacement for borehole 1.

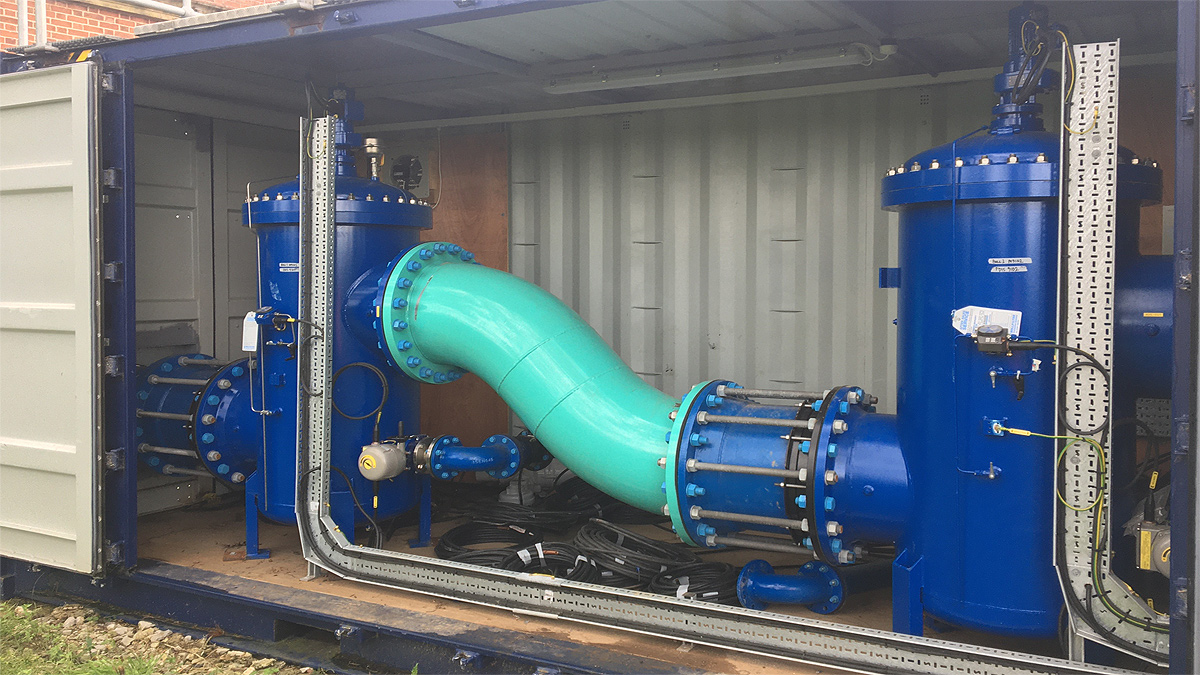

50 micron and 10 micron self-backwashing filtration equipment supplied by Bollfilter UK Ltd – Courtesy of MMB

Maintaining supply for the duration of the project

Poolend is a critical supply source in the area and therefore pumping water into supply needed to be maintained from the site for the duration of the project. The solution developed to ensure that supply was maintained throughout the drilling works was to provide temporary filtration so that BHs 1 & 2 could continue to abstract water into supply during the drilling of BH3 without any risk to water quality. Temporary filtration was utilised to mitigate the risk of sediment arisings from the drilling of the new borehole compromising the quality of the water being abstracted from BHs 1 and 2. As there was no existing issue of high turbidity on site the temporary filtration was removed once the drilling of BH3 was complete.

Boll filters

Boll filters supplied by Bollfilter UK Ltd were used to filter out 50 micron and 10 micron solids. They are self-backwashing filters and ran duty/standby in two streams, working on differential pressure. When the sediment causes increased pressure that filter will automatically backwash to waste and abstracted water will be diverted to the other filter stream.

Amazon Filters

Filters from Amazon Filters Ltd were used to filter out 5 micron and 1 micron solids. They are cartridge filters and are required to be changed when they are blinded up, typically every 10 days when run continuously. There are 5 filter housings and each housing contained 20 filters. To change the filters, 1 filter housing is isolated at a time and each filter is manually removed and replaced.

Containers for temporary filtration

An innovative approach taken by MMB allowed for modified shipping containers to be used for the temporary filtration. This allows for the filtration to be easily removed from site upon completion of the scheme and to be re-utilised elsewhere.

(left) Cartridge filters supplied by Amazon Filters and (right) BH3 headworks – Courtesy of MMB

Poolend BHCM Project: Supply chain – key participants

- Principal designer/contractor: MMB

- Borehole drilling contractor: G Stow PLC

- Borehole drilling contractor: PR Marriott Drilling Ltd

- MCC design and installation: Boulting Group

- Electrical installation: PCS (UK) Ltd

- GRP kiosk: Morgan Marine

- Self-backwashing filtration equipment: Bollfilter UK Ltd

- Temporary filtration equipment: Amazon Filters Ltd

- Borehole pumps: Wilo UK Ltd

- DI pipework: Electrosteel Castings (UK) Ltd

- Turbidity monitors: Sigrist

- Flow meter: ABB

- Temporary sediment trap & sample sinks: Spa Plastics Ltd

- Valves: AVK UK Ltd

- Temporary filtration housings: Cleveland Containers

- GRP self-supporting structural floor, handrailing & staircase: KG Site Services Ltd

Borehole headworks

MMB worked closely with Severn Trent to develop an updated standard for the borehole headworks. The BH3 kiosk has been installed with a removable roof to allow for the borehole pump and associated riser pipes to be removed for maintenance or replacement if necessary, in the future.

Completed BH3 kiosk and surrounding area – Courtesy of MMB

Conclusion

The Poolend borehole capital maintenance scheme is part of a wider programme of capital investment commissioned by Severn Trent Water to drill new boreholes and rehabilitate existing ones. This will help to ensure that water security across the West Midlands is maintained for years to come.