Severn Trent Borehole Capital Maintenance (2022)

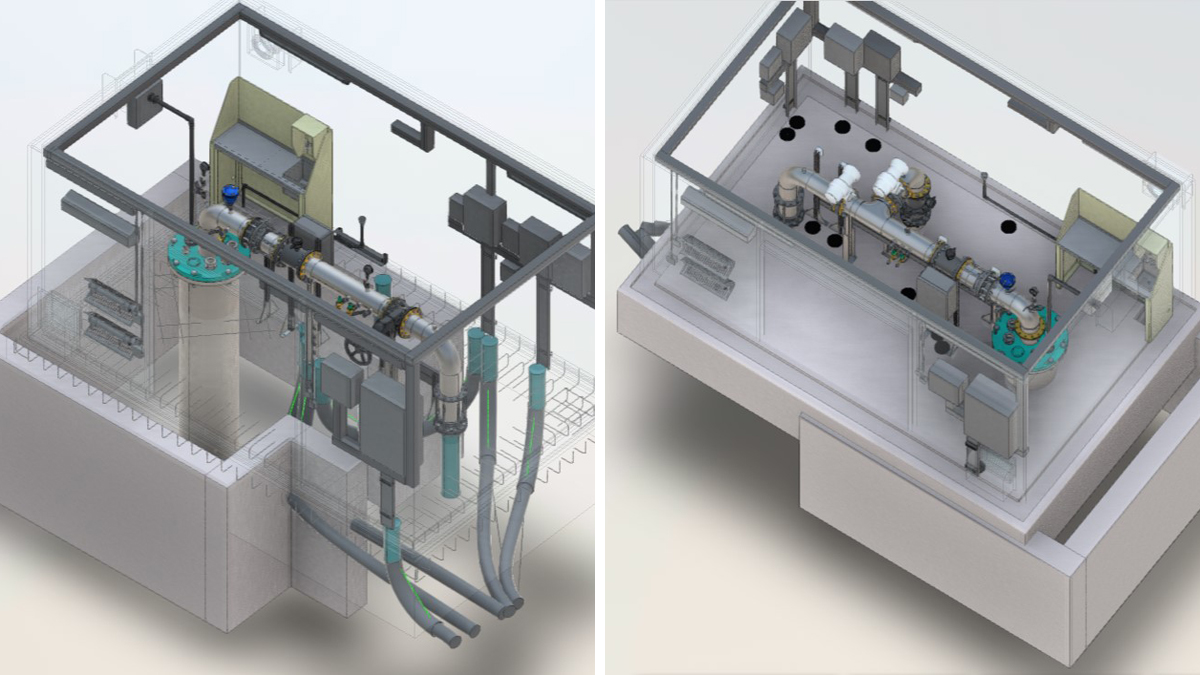

(left) Borehole 3 headworks and (right) mixer and valve bypass arrangement - Courtesy of Galliford Try

Severn Trent is undertaking a programme of rehabilitation works at one its borehole pumping stations (BPS); a groundwater abstraction site consisting of three boreholes (BH1, BH2 and BH3) that provides up to 10 megalitres per day (Ml/d). The three boreholes historically operated in a duty/assist/standby configuration. The site was previously operating at below its intended capacity and with some water quality issues related to the condition of the boreholes. Additionally, the on-site delivery main was lead jointed and prone to burst due to the high working pressure required (10 bar) to introduce the water into the network main. The existing on-site sodium hypochlorite dosing system was unreliable and not sufficient for the intended flows.

Background

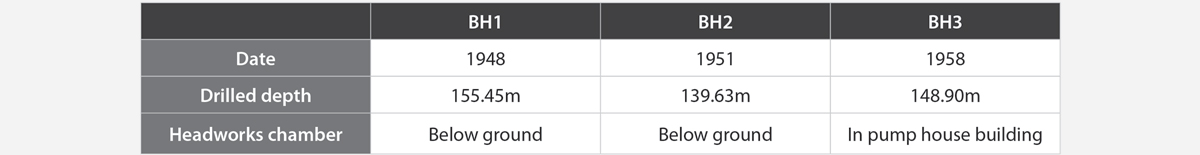

In 2014, Severn Trent graded the existing casing as very poor in BH1 and BH3, and poor in BH2. The boreholes are also nearing the end of the generic asset life for Permo-Triassic sandstone boreholes. Additionally, the unlined section of BH3 is enlarged and potentially unstable as a result of the use of explosive charges shortly after construction, in an attempt to improve yield. The table below details the original borehole construction:

Original borehole construction

Scope

The agreed solution was to:

- Install temporary boll filters and ultraviolet (UV) treatment to protect water quality during borehole relining with the site to remain operational as far as possible.

- Upgrade the on-site delivery main.

- Install a new sodium hypochlorite dosing system.

- Install a temporary overland booster to compensate for loss of flow from the site .

- Reline BH1, BH2 and BH3 (sequentially) to address some of the water quality issues.

- Backfill an existing investigation borehole to eliminate a potential pathway for pollution.

Construction works commenced in June 2019 starting with the temporary and permanent treatment and delivery main works (June 2019 – September 2020), followed by the borehole relining (September 2020 – August 2022). The main contractor for the works was Galliford Try.

(left) Borehole 1 3D model and (right) Borehole 2 3D model – Courtesy of Galliford Try

Key aspects

Replacement of 110m of lead jointed main: A new 350mm HDPE main was installed to replace the existing lead jointed main which was prone to bursts. The main was replaced under three short interventions, as complete site shutdowns in excess of 24 hours were undesirable.

Temporary duty/standby boll filtration: Duty/standby 50um and 10um filters were installed to protect the water quality output from sediment produced during the borehole relining stages. A standard low pressure and high-pressure system was designed for the AMP6 Borehole Capital Maintenance Projects, with a standard setup created by Bollfilter UK Ltd and J&A Engineering Services with a configurable control (MCC) supplied by MCS Control Systems.

As part of the mains installations, a bypass valve arrangement was added to allow disconnection at the end of the scheme.

Temporary UV filtration: A standard D18 UV filtration plant supplied by Lintott Control Systems able to process flows up to 15 Ml/d was installed, also with a bypass valve arrangement to facilitate subsequent removal.

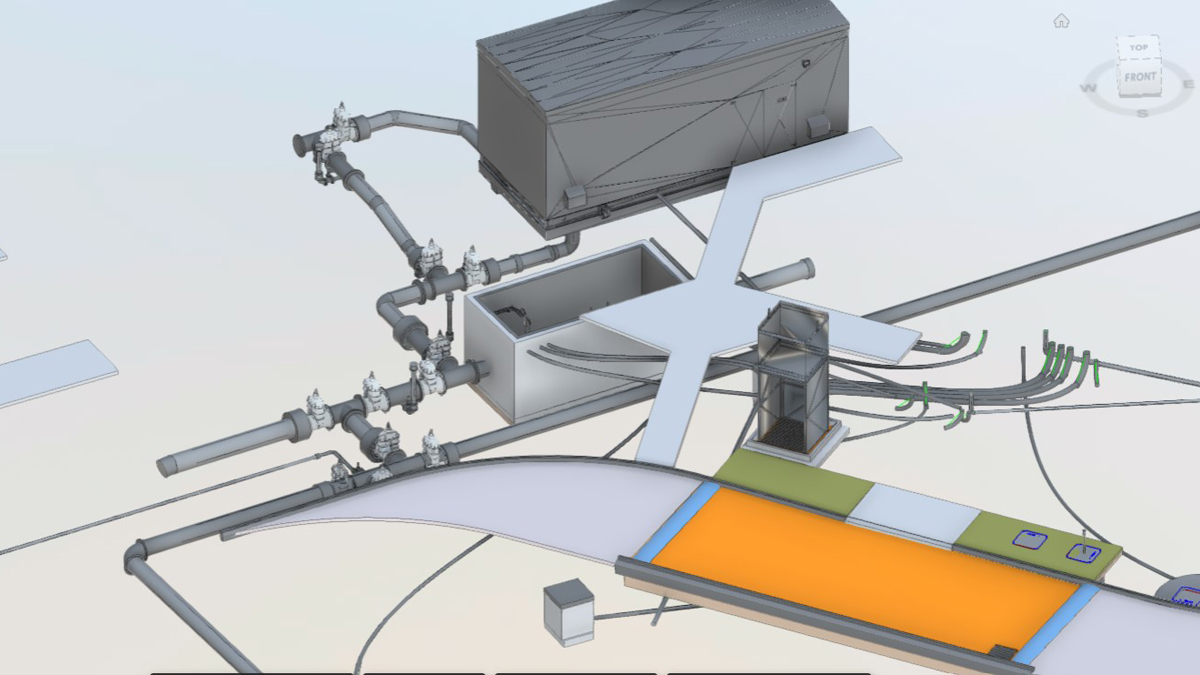

Chemical delivery area 3D model – Courtesy of Galliford Try

Duty/standby sodium hypochlorite dosing system: The existing dosing system was prone to failing daily and was not able to dose correctly at the higher flow rates of 12 Ml/d. A new dosing kiosk was installed to dose via a new mixer installed on the new main. The dosing kiosk was designed by Galliford Try with 2 (No.) 1250 litre duty/standby sodium hypochlorite tanks. The system uses the standard Sevren Trent control panel and software, thus allowing controlled chlorination with a capacity up to 15 Ml/d flows. The old dosing system was then decommissioned.

Temporary overland pumping: A temporary overland pumping station was installed to compensate flows between reservoirs, thus allowing full site shutdowns of 72 hours or longer. This enabled borehole relining activities such as grouting new casings in place or cleaning. These activities required full site shutdown to prevent migration of grout or sediment between the boreholes, hence reducing water quality risks within the aquifer. This also provided for improvement in the program by allowing some of the relining works to be carried out simultaneously, with extended shutdowns.

Supply chain – key participants

- Main contractor: Galliford Try

- Borehole relining: Marriott Drilling Group

- Borehole relining: York Geological Services

- Boll filtration: Bollfilter UK Ltd

- Civil engineering: Access Direct Site Services (ADSS)

- Mechanical: J&A Engineering Services

- Electrical: AMI Electrical

- UV disinfection: Lintott Control Systems Ltd

- MCCs: MCS Control Systems

- MCCs: BGEN Ltd

- Borehole pumps & headworks: Flowserve

- Mixer: Statiflo International Ltd

- Pipes: Plasflow Ltd

- Overland booster pumping set: Selwood

Sodium hypochlorite primary dosing plant and delivery area – Courtesy of Galliford Try

Borehole relining

Borehole 1: Relining works commenced on 5 October 2020 and the borehole was back in use, to supply on 14 June 2021. The sequence of work was as follows:

- Extend the casing to above ground level and backfill the chamber.

- Removal of dropped stilling tubes by fishing.

- Clean the borehole by airlifting.

- Reline the borehole to approximately 5m below the existing casing.

- Test-pump the borehole (step test and 7-day constant rate test).

- Install a plinth, permanent Flowserve pump, security rated kiosk and new headworks pipework.

The existing manual washout pipework was modified to install a new diversion chamber housing a washout and supply actuated valves.

Borehole 2: Relining works commenced on 10 November 2020 and the borehole was back in use on 14 June 2021. The sequence of relining was the same as for BH1 (above).

Borehole 3: Relining works commenced on 6 September 2021. Work was complicated by several factors as follows:

- The borehole is situated within the pumphouse building with no roof access. This prevented the use of a mobile crane and reliance was placed on the existing gantry crane with a lifting capacity of 12.5 tonnes.

- In order to stabilize the borehole, given the damage caused by explosives in 1951, the design incorporated both casing and screen to the full depth, intended to be installed as a single liner.

- The crane capacity required a new design to be developed, installing the casing and screens as two separate liners.

- Casing and screen lengths (and rising main lengths) were limited by the height of the crane.

- Having purchased mild steel casings and screens, DWI regulations changed and initially called for a stainless steel liner. This was subsequently amended to allow mild steel liners subject to specific product approval.

Borehole 3: (left) casing installation and (right) test pumping – Courtesy of Galliford Try

Having overcome these issues, work proceeded in a similar manner to BH1/BH2. Experience gained whilst relining BH1/ BH2, and the constraints of working with a gantry crane, led to an improvement in the fishing techniques used for removing dropped stilling tubes, of which there were a total of 14. All were removed successfully.

The downhole works for BH3, the individual borehole tests and then a 6-day combined pumping test with all three boreholes (total 132 Ml/d) was successfully completed on 6 May 2022 and the permanent pump was installed on 20 May 2022 by Flowserve.

Biodiversity

Every attempt was made not to prune or remove any existing trees on the site, however some tree work had to be undertaken, particularly at BH1 which was adjacent to a wooded area, to provide access for the mobile crane and drilling rig. Reinstatement around the site includes wildflower meadow and some tree planting, as well as reinstatement of areas of grass impacted by the works.

Challenges

All the works for the borehole pumping station were carried out in a phased manner ensuring the least disruption to the water output from the site. Challenges that the team had to overcome were:

- Impact of Covid-19 delays.

- DWI changes in specification (borehole liners).

- EA abstraction and discharge restrictions.

(left) UV kiosk, mixer and valve arrangement, (top right) boll filtration kiosk and (bottom right) Borehole 1 kiosk – Courtesy of Galliford Try

Status

At the time of writing (September 2022), all three boreholes have been relined successfully and the permanent pumps have been installed with new above ground headwork and new primary dosing plant. The boll filtration, UV filtration and sodium hypochlorite primary dosing plant have all in supply since September 2020. Borehole 1 and Borehole 2 have been operational since June 2021 and can supply up to 9Ml/d.

Borehole 3 is awaiting an abstraction license variation due to casing depth change. Once Borehole 3 is available the site will be able to supply up to 12Ml/d, and the final state of the plant will be for all three boreholes to run without the boll filter and UV filtration in line.