BRP – Treated Water Project – Birmingham Resilience Project (2018)

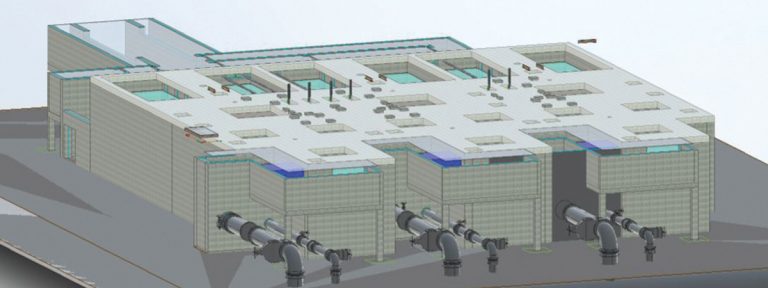

Aerial view of sand ballasted lamella and rapid gravity filters under construction Courtesy of Severn Trent Drone Team

Since the beginning of the 20th century, the Elan Valley Aqueduct (EVA) has conveyed raw water 118km from the Elan Valley in Wales under gravity to Frankley Water Treatment Works (WTW) in Birmingham. The treatment works was inaugurated at the same time as the EVA and has treated water, to supply the residents and industries of the city of Birmingham, for over 100 years. During this time the treatment works has evolved to see the original sand filter units replaced with much more modern plant and equipment to ensure that improved water quality parameters are met. The EVA now requires some important maintenance work to be undertaken, and to ensure resilience of supply to customers in Birmingham, a new treatment stream is required at Frankley WTW; this case study details the work being undertaken.

Project background

EVA maintenance work will require the aqueduct to be shut down and drained a number of times and for a number of weeks each time to complete elements of this work.

There is currently some capability to deliver and treat river water from the River Severn using the high lift pumps at Trimpley and the granular activated carbon (GAC) plant at the WTW. This facility enables the EVA to be shut down for inspection for 5-7 days at a time.

The duration of EVA shutdowns, required for maintenance work, exceed the current river water delivery, raw water storage and treatment capability of the WTW. To facilitate the EVA maintenance work and ensure that water demand is met during EVA shutdowns, the WTW is being upgraded with a new treatment stream capable of treating raw river water.

SBLs under construction – Courtesy of Severn Trent Drone Team

The river water will be pumped to the WTW from the River Severn using the existing transfer capability and a new raw water pumping station being installed as part of the Birmingham Resilience Project at Lickhill. The total river water supply and treatment capability of the new treatment stream will be around 25% less than the existing EVA water treatment works capacity and will be supplemented through additional treated water from the supply network to make up the shortfall during an EVA maintenance outage. The new treatment stream can also treat EVA water providing additional treatment capability and flexibility at the WTW.

Existing WTW

The WTW today comprises two parallel process treatment streams fed from Bartley and Frankley Raw Water Reservoirs, both supplied with water from the Elan Valley. Frankley Reservoir can also receive River Severn Water for blending and treatment using the GAC plant on site. Each process stream includes dissolved air flotation (DAF), rapid gravity filters (RGFs), pH correction and disinfection with chlorine contact time being provided by three contact tanks. The GAC plant is dedicated to one stream following the RGFs and is brought in and out of service depending on the volume of River Severn raw water supplied to the WTW and for EVA inspection shutdowns.

SBLs under construction – Courtesy of NMC PLC

Future process

Severn Trent Water Ltd (STWL) has promoted the Treated Water Project to provide a new process stream at the WTW capable of treating the current raw water feed from the EVA and also raw water from the River Severn. The treatment capacity of the new process stream will be greater than either of the existing streams. Once the project is complete, STWL will operate the WTW as a three-stream water treatment works which will provide improved resilience to its customers. The new treatment stream includes the following processes:

- Pesticides removal: The increasing levels of the pesticide metaldehyde in the River Severn lead STW to select powdered activated carbon (PAC) for pesticides removal. PAC storage and dosing systems are to be constructed at the existing river abstraction site at Trimpley and also on the new break-pressure tank on the main from Lickhill Pumping Station. The delivery mains provide contact time for the PAC and the raw water reservoir will facilitate settlement of PAC prior to water treatment.

- Clarification: The existing DAF process is deemed sub-optimal for the treatment of raw river water due to the amount and nature of the solids it carries, so STW has selected the sand ballasted lamella (SBL) process as the most suitable solution for treating both river and EVA water, specifically Actiflo®. As this is a new treatment process to STW and in order to gain confidence in the process, pilot trials were carried out using a trailer mounted Actiflo® located at Trimpley WTW.

- RGFs: New rapid gravity filters are being constructed for the new process stream with associated clean and dirty backwash systems. The new clean and dirty backwash systems will also service the existing RGFs, enabling the old clean backwash tanks, which are at the end of their asset life, to be removed.

- Chemicals: The new treatment stream includes the construction of its own dedicated chemical treatment dosing plant, to support the new clarification, filtration and sludge processes.

- Sludge treatment: Due to sewer capacity limitations and programme delivery risk associated with the time required to increase sewer capacity, the decision was made to provide a new sludge treatment plant which will service the whole site, replacing expired assets and with the capability to treat sludges from the EVA and river raw water supplies. The plant maximises water recovery which is recycled for treatment and minimises the sludge discharged to sewer.

RGFs under construction – Courtesy of Severn Trent Drone Team

Contract award

The contract to undertake the construction work was awarded by Severn Trent Water Ltd to nmcn PLC (now Galliford Try) in June 2017. nmcn separately formed a joint venture with the Korean industrial giant owned Doosan Enpure Ltd to deliver the project. The joint venture is called the Doosan North Midland Alliance (DNMA). The construction works is valued at around £120m with completion of commissioning of the new stream currently programmed for 29 February 2020, in advance of the OFWAT deadline set out in the final business plan of 31 March 2020.

Enabling works

The programme is recognised by STWL as challenging due to the scale and complexity of the project. Therefore, whilst contract negotiations took place to select the main contractor to deliver the project, enabling works contracts were let to:

- Remove 40,000m3 of spoil, mounded in the area of the new plant.

- Diversion of critical service mains away from the working area.

- Provide access road improvements within the site for construction use.

- Install a new site office for 100 management staff and designers.

This work was completed prior to the main contractor’s arrival on site and provided an advanced platform to progress works from.

SBLs under water-tightness test – Courtesy of nmcn PLC

Design

The design is complex, incorporating a variety of treatment processes requiring chemical dosing and control. In addition to the process and MEICA requirements of the design, there are also resilience drivers and security requirements to be considered, that extend the scope and complexity of the design. Some of these are required to be developed and agreed with the client as the design develops.

Given the timescales for delivery, the design and build process is truly fast track, there is little time to rectify design and construction errors. It is vital therefore that the design is right first time. To facilitate this objective, a number of initiatives have been adopted:

Early contractor involvement: STWL appointed Stantec UK to undertake feasibility study work and subsequently to produce a very detailed outline design for the purpose of tendering. Prior to awarding the contract to NMC, two other main contractor’s had separately entered into partnering contracts with STWL to deliver the project. Although they were ultimately unsuccessful in securing the construction works, they provided essential support to the EIA study and peer reviewed and modified the outline design to produce an overall design optimised for construction.

Co-location: From the day of contract award, DNMA has populated the management offices on site with key project management staff and a full design capability. STWL has also provided dedicated technical, operational, commercial, contractual, and project management staff based alongside the contractor’s site organisation to facilitate rapid decision making, change management and assurance to support and expedite project delivery.

Innovation: BIM has been used effectively throughout the design stages to ensure all design disciplines and key stakeholders are engaged in the design process and that the off-site fabrications will fit seamlessly with the on site elements when delivered. During the design development DNMA used the very latest technology such as virtual reality headsets, taken fro

Production control/collaborative planning: Techniques have been effectively implemented on this project with programme risk items identified early and eliminated or mitigated to avoid programme delays.

Construction

BIM model of sand ballasted lamellas – Courtesy of Adrian Hill of nmcn PLC

Sand ballasted lamella (SBL): The SBLs are the first structures to be constructed, which are substantial, complex, in situ concrete structures designed around Veolia Water Technologies’ Actiflo® process arrangements and requiring close liaison with Veolia Water Technologies to ensure those process requirements are met whilst also ensuring constructability of the tanks. Construction of these structures commenced in November 2017 and water-tightness testing commenced in June 2018.

RGF units: In parallel with the construction of the SBLs, the RGF units commenced construction. This is also a large and complex in situ concrete structure comprising 18 (No.) individual treatment cells which will be water tightness tested as construction progresses and each cell is completed. MEICA installation will follow on directly in each successfully tested cell on a rolling programme to completion.

Clean backwash water tanks (CBWT) and dirty backwash water tanks (DBWT): These two structures each approximately 40m x 40m x 5m deep in situ reinforced concrete tanks, are separately built within existing sand filters with the benefit of limited buried services to contend with, but partial demolition of heavily engineered perimeter walls to manage.

Both tanks have adopted identical design philosophies incorporating being split into two compartments to allow future inspection and maintenance and having pumping arrangements capable of pumping from either compartment.

Sludge plant area

The new sludge plant will be constructed on Severn Trent owned fields adjacent to the existing works. This area has required a great deal of earthworks in preparation for the new plant which will be accommodated in this area. These earthworks are substantially complete in readiness for the new tanks and buildings which will provide sludge treatment.

Sludge area earthworks preparation completed – Courtesy of nmcn PLC

Progress/conclusion

Construction of the new treatment stream at the WTW is well underway in readiness to facilitate maintenance of the EVA and provide resilience through the capability to treat an alternative supply to the current Elan sourced water. Design and construction progress has necessarily been rapid and will continue to be so.

Diversion of critical service mains away from the working area – Courtesy of nmcn PLC

There is a tremendous spirit and drive amidst the relentless pressure to deliver the project and a great deal of pride and determination that this project will be delivered to specification and in advance of the completion date.