Earl Shilton STW (2019)

Work in progress - Courtesy of MWH Treatment

Earl Shilton Sewage Treatment Works (STW) is situated in south west Leicestershire and serves a population equivalent of 11,833 comprised mainly from domestic sources from Earl Shilton and Barwell. There has been a STW in this location since the 1960s and the current process workstream includes preliminary treatment, primary settlement, secondary filtration, secondary settlement and tertiary filtration. The STW catchment is expecting an increase in domestic population of approximately 15% over the next 10 years.

Tighter effluent consent

Following river modelling, the Environment Agency required a works permit change to achieve a total phosphorus effluent limit of 0.5 mg/l to meet the Water Framework Directive (WFD) objective and an ammonia effluent limit of 1 mg/l to meet the Fisheries Directive driver by 2020. The existing treatment process stream required change to meet the stringent new conditions.

Severn Trent promoted the major process enhancement project as part of the AMP6 programme and appointed MWH Treatment (MWHT) to undertake the solution development, detailed design, and construction of the new assets.

Optioneering

Following a number of optioneering workshops, the lowest whole life cost TOTEX efficient solution chosen to reliably achieve the permit was to replace the 16 (No.) secondary filters with a 3900m3 activated sludge plant (ASP) providing a seven-hour retention period, 2 (No.) final settlement tanks (FST) with ancillary flow control and refurbishment works to primary tanks.

Project initiation with the whole supply chain

To create a vision of how best to design and build the ASP and FSTs, the positive step to involve all the stakeholders at the earliest point in delivery was taken. Engaging with the supply chain early in the process gave an opportunity to augment and mould the design and delivery strategy incorporating their innovative ideas e.g. during collaborative planning sessions, every new asset was evaluated for off-site build potential. The team decided to take construction off-site and to modularise, wherever possible, thus overcoming conventional construction mind-sets.

- Client: Severn Trent

- Main design & build contractor: MWH Treatment

- In situ civils: Bells Formwork

- Precast civils: A-Consult Ltd

- Mechanical installation: Servomac

- Electrical installation: Elsym

- Sludge thickening: Huber Technology

- Aeration System: Eliquo Hydrok Ltd

- Bridge scrapers: EPS Water

- Kiosks: Morgan Marine

- MCC: Total Automation & Power

- Structural steelwork: Galliford Try

- Safety showers & eyebaths: Aqua Safety Showers International Ltd

Digital delivery strategy

The project team targeted optimising digital delivery using developing digital engineering tools to increase efficiency at initiation, design development, assembly and ultimately client operational stages in the project lifecycle.

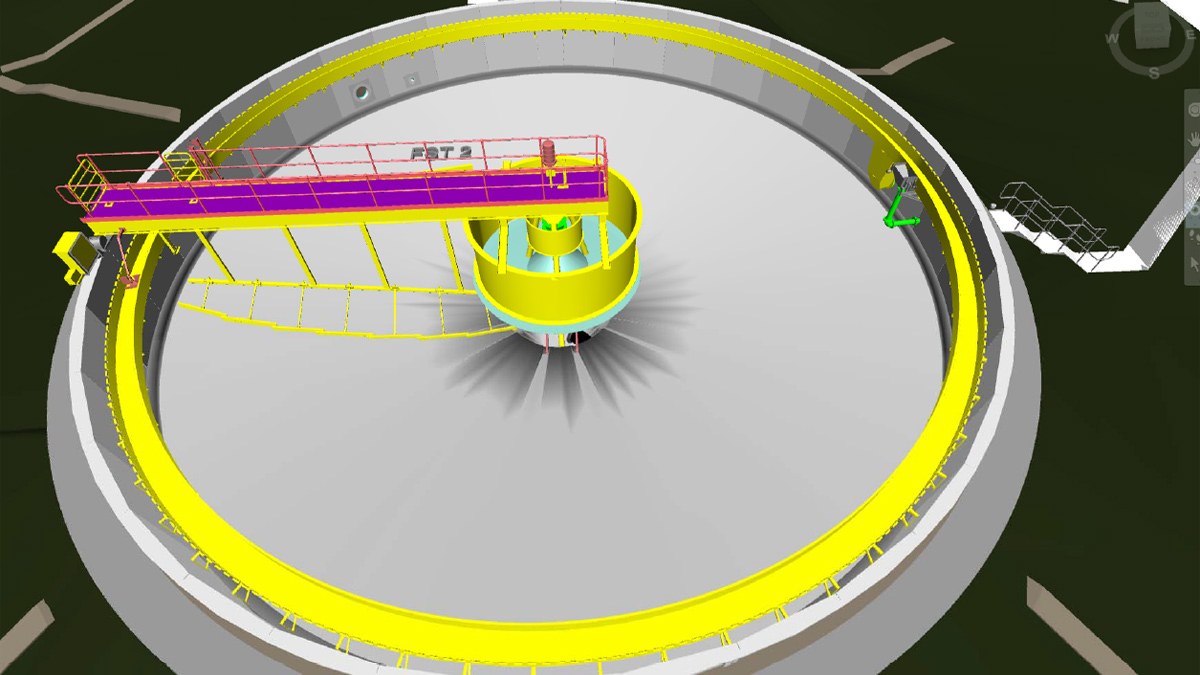

FST BIM model – Courtesy of MWH Treatment

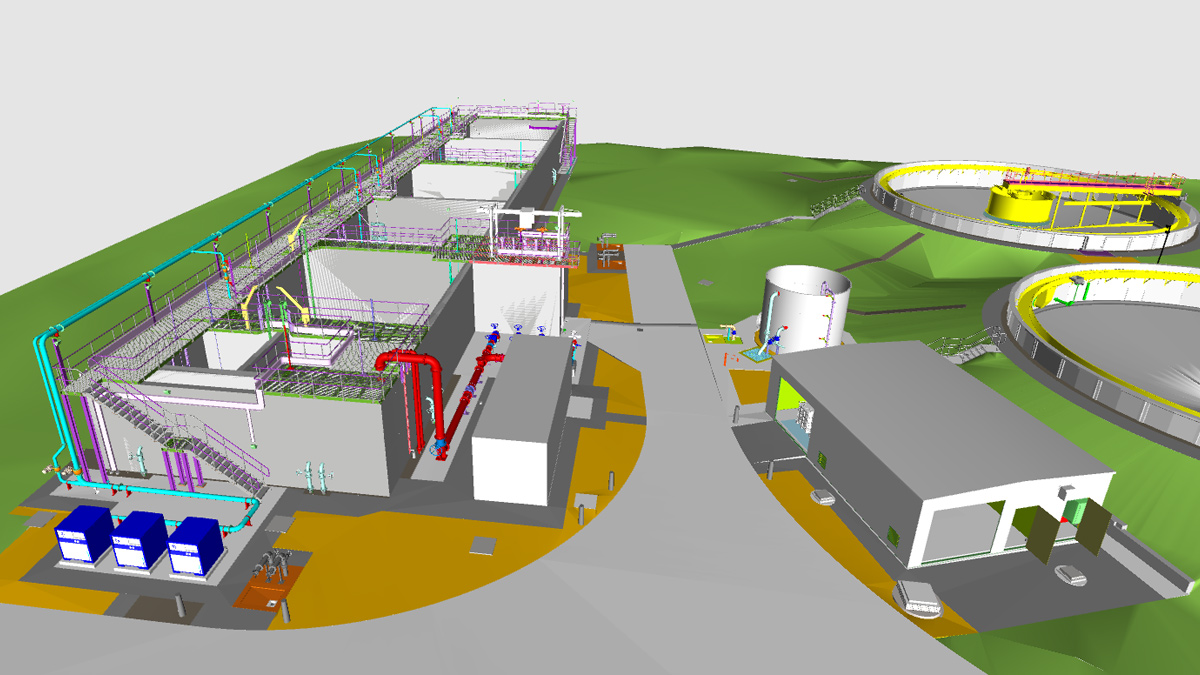

MWHT undertook both a full digital survey of the site and utilised a drone to take aerial images of the site. These were used as the basis of the 3D model but additionally this digital information and imagery was also actively used in the induction process to develop visual awareness of both the works layout and the impact on access and the local community.

Information was updated as the project progressed giving visitors contemporary overviews of the works and the ongoing construction activities before stepping out onto site.

Earl Shilton STW – BIM model – Courtesy MWH Treatment

Process design

MWHT designers worked closely with the Severn Trent Process Design Engineering (PDE) team to mitigate the impact of tip leachate which would normally prompt the ASP to be sized at approximately 7,000m3. Through using an enhanced recirculation system, allowing final effluent to be used to dilute incoming effluent during peak times, the managed design load enabled a (circa) 45% reduction in ASP volume to 3900m3, saving in construction time, cost and carbon footprint.

Increasing ASP effectiveness was achieved by increasing retention time to seven hours with process flexibility using both a swing zone allowing optimisation of nitrification and de-nitrification and anoxic capacity flexibility. This control will allow Severn Trent to optimise for both process operation and OPEX efficiency.

Digital design collaboration

The design included the use of digital design and collaboration software (Autodesk BIM360), and the Synchro 4D digital planning tools. Whilst this approach was adopted across the project, the impact on the 2 (No.) 23.5m diameter FSTs demonstrated its optimal use.

Three options for the wall construction were considered including in situ concrete, GRP and precast post stressed. Through early supply chain involvement in the design optioneering, the chosen solution was precast post-stressed modular technology offered by A-Consult Ltd based on the overall project cost driven by purchase and programme benefits.

Post tensioning – Courtesy of MWH Treatment

The benefits of using this technology was shared through collaboratively developing a 3D Autodesk model of both the final installation and the 4D process of its assembly when combined with the Synchro tool. The planned assembly phase saved 6 weeks per tank with the benefit of the precast sections made in a more controllable factory environment reducing both safety and quality risks.

Each tank’s wall panels were erected sequentially in a single day per tank with circumferential steel tendons post stressed by jacking and anchoring to the buttress panel. Subsequent casting into the base and seal the wall tops took two days when the tank was immediately available for water testing and mechanical fit-out.

The team embedded project learning with the reuse of cast-in accessways into key structures. These low level features removed the need to use ladders/scaffolding to climb over the walls. They are simply blanked off and can be reused by the client later if required.

Cast accessway – Courtesy of MWH Treatment

Electronic induction

The project has trialed bulk induction using an electronic GDPR compliant induction system for all workers and visitors. This system of completion online prior to arrival allows the site induction to focus purely on the key site-specific dynamic issues enabling people to start work more promptly. Over 840 people have used this system, typically saving over 1095 hours of site time. The digital induction includes a video of the access routes and access restrictions including narrow lanes, two schools and resident parking enabling drivers and delivery persons to clearly understand the preferred access routes and restrictions before setting off for site.

Drone aerial image – Courtesy of Owen Daviess

Community consideration

Working with the Community in Mind was a core consideration throughout the works and the project registered with the Considerate Constructors scheme. One example was to minimise risks between people and traffic on the Severn Trent access track which is a popular route for dog walkers. The novel solution, in addition to normal signage, was to provide high visibility arm bands free of to those wishing to share the use of the access road.