Killingworth & Longbenton Water Management Ph 3 (2019)

Killingworth Lake 2019 - Courtesy of Esh Stantec

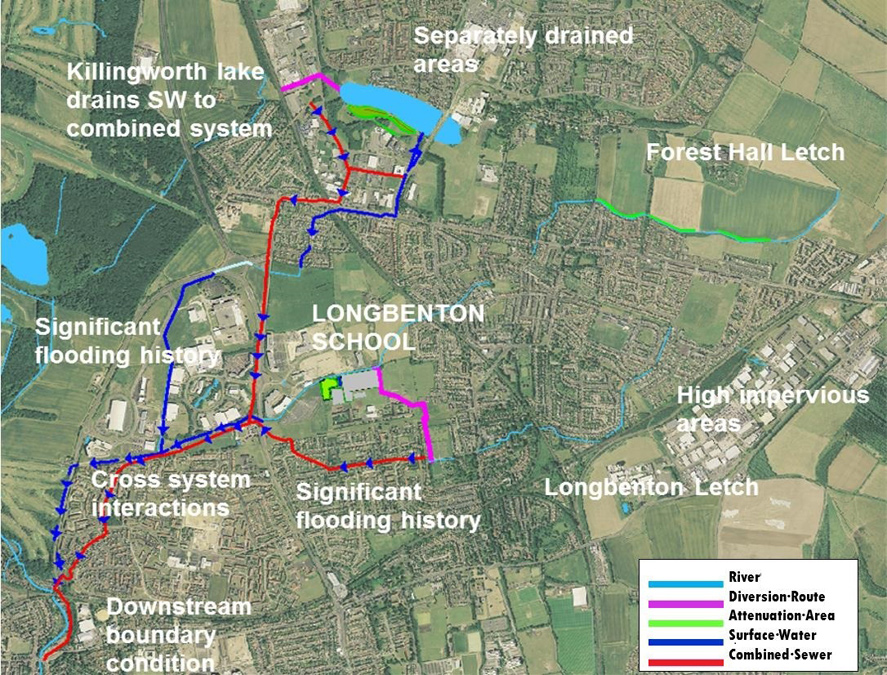

Since 2010 the Risk Management Authorities (RMAs) for the Tyneside Drainage Catchment have developed and implemented an area-based prioritisation process to identify and investigate those drainage areas at greatest risk of performance failure. The Killingworth, Longbenton and Forest Hall area was one of those areas identified, something supported by the published 2010 Strategic Flood Risk Assessment which identified Longbenton as having the highest risk of flooding. The integrated nature of the drainage system means that it is not practical to assign responsibility for managing the flood risk to a single RMA. The RMAs therefore agreed to the joint delivery of an integrated drainage study to fully understand the issues, opportunities and benefits associated with a collaborative approach to risk management in the area. The study concluded that a collaborative approach could deliver significant benefits to both the residents and the environment, particularly in the area of flood risk reduction to 3,594 properties.

History of flooding and background

The catchment contains over 20,000 properties. Based on a detailed Integrated Catchment Model (ICM) 3,594 properties are considered to be at risk of flooding, which is supported by historic evidence. Over 500 properties have been formally recorded as being affected by flooding. As flooding has historically been subject to under-reporting, this is considered an underestimation of what has actually occurred. Northumbrian Water Group (NWG) has carried out previous works in the area to address property flooding associated with sewer incapacity. North Tyneside Council (NTC) schemes have included the creation of attenuation areas and bunds on fields in Forest Hall.

The developed areas of the catchment are a mixture of domestic housing, retail businesses, schools, industrial estates and business parks with associated infrastructure.

Northumbrian Water (NWG), The Environment Agency (EA) and the local authority North Tyneside Council (NTC) entered into a partnership agreement to work together to tackle flooding.

This partnership and a collaborative approach allowed the organisations to share funding, jointly procure design and construction services and work together to find a solution that would benefit all partners. By working in a partnership this allowed the sharing of wider knowledge which resulted in a greater understanding of the problem and the development of a solution that would provide greater benefits all round.

A sustainable approach to the flooding was agreed by all the partners as the way forward. A sustainable approach would provide the most suitable solution as well as providing great benefits to the whole community in the form of:

- A more innovative solution rather than a solution based on conventional drainage systems.

- Added value opportunities such as increased amenities in the area, enhanced biodiversity and ecology, as well as educational opportunities for the community.

- Engagement opportunities with the community leading to greater support for the scheme and understanding of what the partners were trying to achieve.

Schematic of system and location of SuDS features – Courtesy Esh Stantec

The solution

The solution comprised SuDS measures being delivered at multiple sites in a phased approach to manage surface water. Killingworth Lake phases 1 and 2 were featured in detail in UK Water Projects 2018 and Phase 3 is the focus of this paper.

The Phase 3 works were at Killingworth Lake and involved the provision of storage and surface water separation.

Phase 3

Killingworth Lake is a large seven-hectare lake holding the majority of the surface water generated by Killingworth as well as providing a recreational open space in the town. Previously the lake overflowed into the combined system taking up critical capacity and putting properties in the catchment at risk of flooding.

Excavation of the basin (2019) – Courtesy of Esh Stantec

This scheme involved providing additional storage capacity within the lake of 3000m3 in the form of a flood storage basin created along the southern perimeter of the lake. A new overflow weir was constructed on the lake edge, so when the water in the lake rises above a specified level, water spills over into the new detention basin which provides storage capacity.

The lake was disconnected from the combined and foul sewerage systems which was the previous arrangement, thus reducing the flood risk within the catchment.

Excavation of the basin (2019) – Courtesy of Esh Stantec

Providing this increased storage capacity and also controlling the rate at which the stored flood water is returned back to the sewer network, reduces the risk of flooding in the catchment. The basin connects back into the existing system from two controlled outlets. The eastern outlet discharges to the surface water system at a controlled rate and the western outlet discharges to a new DN225 surface water sewer which then connects into the new DN900 surface water overflow sewer constructed from Killingworth Lake to an existing culvert within the Harvey Combe Industrial Estate, which then crosses under the East Coast Mainline railway, approximately 500m to the west of the lake. The culvert eventually discharges downstream to the West Moor Tributary.

The development also comprised ancillary works including new public footpaths, a new access off Southgate (the highway dissecting the lake), new fishing platforms, relocation of existing furniture/picnic tables, new public information signs, floating islands, bat and bird boxes and new wildflower bedding surrounding the lake.

Weir from Killingworth Lake into the basin (2019) – Courtesy of Esh Stantec

Design approach

The design was undertaken by Esh-Stantec, a joint venture between Esh Construction and Stantec UK, with an approach aimed at applying the latest best practice for surface water management schemes, which required a wider design team with a range of different skills. A landscape architect developed a natural look for the basins and a landscaping and planting scheme for the lake area. An ecologist provided advice on planting and tree removal to facilitate the scheme. 3D visualisations were prepared by a specialist graphics team.

The study used an integrated model which included a representation of the existing sewerage system, surface water drainage system, watercourses and runoff from fields and greenspace within the catchment. The model quantified flood risk at the catchment properties which was required to obtain FDGiA funding.

The model was verified against flow surveys undertaken across the sewer network with rain gauges and flow monitors being installed. A flood risk assessment was undertaken using the Stantec Flood Risk Tool.

Civil 3D was used throughout the scheme to develop the solution and visualisations were created using the 3D model with a landscaping tool, so they could be used for customer events which were held at various stages to involve the community in the scheme. The design included the following elements:

Detention basin: The basin within Killingworth Lake Park was designed based on guidance in the CIRIA C735 2015 document and was further refined following consultation with the North Tyneside Parks Team to enable maintenance of the landscaped basins in the longer term. The basin was designed to have a natural appearance and is grassed to blend in with the open parkland with sloping sides at a maximum gradient of 1 in 4 to allow the grass to be maintained and mowed and to allow easy access and egress from the basin. The basin narrows in the middle to avoid a group of trees to the south which were protected during construction.

The majority of the time, water will remain in the lake itself with the overflow to the basin only occurring during intense rainfall, so the basins will remain dry and therefore usable by the public for the majority of the time. Using SuDS on this scheme over a conventional storage system reduces the carbon footprint as less concrete and raw materials are used, and the costs are also reduced.

An inlet weir was designed to allow the existing lake to “spill” into the detention basin. The weir consisted of precast concrete culvert sections. A footpath was designed around the detention basin which crosses the weir. The weir was designed with a fish screen to ensure fish from the lake do not enter the basin and become stranded or make their way into the downstream drainage system.

Access road: A new access road was designed from Southgate up to the edge of the basin to allow future maintenance by the North Tyneside Parks Department. The road was designed in accordance with the North Tyneside Council Highways Specification.

Fishing jetties: As part of the design, three new fishing jetties were included for the local anglers who use the lake. The jetties were designed as a continuation of the lake perimeter footpath with raised edges and were built at the edge of the lake to allow access for disabled/able-bodied anglers.

Footpaths: A new footpath network was designed to provide a circular walk around the basin area. In the area above the inlet weir the footpath sits above the weir level, so a handrail was included to ensure the safety of pedestrians. The footpaths were designed to be 1.8m wide and constructed in bitmac with a pin kerb. The footpaths were designed to North Tyneside Council Specification following discussions with the Rights of Way Officer.

Surface water sewer overflow from lake: A new surface water sewer, with associated manholes, was deigned to take the overflow from the lake downstream. The new DN900 surface water overflow sewer conveys the overflow from Killingworth Lake to an existing culvert within the Harvey Combe Industrial Estate which then crosses under the East Coast Mainline railway, approximately 500m to the west of the lake. This culvert then discharges downstream to the West Moor Tributary, which passes through Gosforth Park Nature Reserve, a private SSSI managed by the Natural History Society of Northumbria.

The depth of the lake at the sewer inlet from the lake was less than 1.0m, so 2 (No.) culvert sections of depth 0.4m were proposed to give an equivalent cross-sectional area, from the lake edge to the first manhole, a length of 18m. In order to utilise the full capacity of the culvert, a maximum invert level of 58.3m AOD was set at the inlet to the culvert from the lake to ensure the soffit level is within the maximum weir level of the relief weir of 58.7m AOD and below the spill level to the basin for optimum performance. This ensures maximum pass forward flow before spilling into the basin.

Construction of the DN1200 Overflow Sewer using Pipejacking (2018) – Courtesy of Esh Stantec

Construction approach

The design and construction was undertaken by Esh Stantec as a joint venture under an NEC Option C contract. The Phase 3 works at Killingworth Lake completed the Killingworth and Longbenton Scheme with construction commencing in September 2018 and substantial completion in May 2019. The construction works included the following elements:

Detention basin earthworks: The works consisted predominantly of earthworks which were constructed using 3D GPS with work undertaken by sub-contractor, Groundwork Services. The ground conditions comprised clay soils which eliminated the need for the basins to require lining. The bunds were constructed from clay soils excavated from the site. Civil 3D was used to calculate the cut and fill required and spoil from the excavations was reused on site to create bunds to minimise the amount of spoil taken off site.

(left) Construction of the DN1200 overflow sewer using pipejacking. The two drives meeting between Manhole 2 and 3 (2018) and (right) construction of the DN1200 and DN762 overflow sewers using pipejacking and auger boring techniques. The two drives meeting at Manhole No.3 (2019) – Courtesy of Esh Stantec

Pipeline construction: The works to construct the new DN900 overflow from the lake involved a section of trenchless construction which was undertaken by specialist contractor Pipeline Drillers. Trenchless construction was undertaken to avoid disruption to two sensitive areas.

A section was undertaken under Station Road which avoided disruption to the highway and the need for a road closure and a further section was undertaken within the vicinity of SIG Roofing within the Harvey Combe Industrial Estate in order to avoid disruption to this business. Within Harvey Combe, 53m of DN1200 pipejacking was undertaken and 58m of auger boring of twin steel DN762 pipes were undertaken crossing the highway.

Twin pipes had to be utilised for this section due to the presence of services under the highway. In order to clear the services with adequate clearance twin pipes were used in a guided auger bore rather than a DN1200 pipe jack. Twin 762mm diameter permanent steel pipes were installed by guided auger bore using the RSHV system followed by lining of the pipes with a cured in place liner.

This avoided the need to divert services which included a strategic water main serving the Killingworth catchment area. The augured pipe was close to the strategic water main so prior to installation of the augured pipe a trial hole was undertaken so the underside of the water main was visible while the auger passed the main. The trial hole remained open and the water main was visually monitored to ensure safe passing.

Landscaping & planting: The planting, landscaping and reinstatements were undertaken by specialist sub-contractor WL Straughan & Son Ltd, who are experienced in this area. Works undertaken included the landscaping of the new basins and all the seeding and planting works agreed with North Tyneside Council Parks Department.

The floating islands were undertaken by specialist contractor Biomatrix. Floating Islands, also called floating treatment wetlands, provide natural water quality improvement and add beauty to any waterscape with colourful native and selected plant species. Ready to install components, available in natural shapes, offered a cost effective and attractive focal point to the lake, supporting natural, maintenance-free ecological water restoration processes.

These floating ecosystems were installed on Killingworth Lake to give plants and animals a place to live, both above and below the water. Fixed in the centre of the lake, they will help to keep the lake clear, with their plant roots sucking up nutrients and cleansing the water.

This is the first time Northumbrian Water has used floating ecosystems as part of a project, to help improve water quality and biodiversity.

Construction of the Floating Islands by Biomatrix (2019) – Courtesy of Esh Stantec

SuDS approach

This scheme has maximised the opportunity to use soft engineering techniques with multiple benefits including reduced costs, over a more traditional solution using underground storage tanks. The solution does not require mechanical or electrical systems and uses gravity therefore saving energy and reducing operational costs.

SuDS offer wider benefits than traditional techniques as they can also improve water quality, provide new habitats, enhance biodiversity, create community spaces and provide educational facilities and benefits. At Killingworth Lake, the SuDs areas provided at this site forms part of an amenity area in keeping with the Killingworth Lake Park. Early engagement with the North Tyneside Council Parks Department and ecologist has resulted in an enhanced area for the community.

Construction of the Floating Islands (2019) – Courtesy of Esh Stantec

Community engagement

Early customer and community engagement were crucial to the success of the project. A customer liaison team was engaged to manage customer concerns. The project team engaged very early on and held extensive consultations with anyone affected by the works, community groups, the local history group, landowners, English Nature and the Tyne Rivers Trust as well as the wider community. This allowed for joint working and a scheme resulting in all round benefits for everyone.

The scheme was well supported by the local community and this continued throughout the construction phase which resulted in a smoother construction period and a positive response from the community. Children in North Tyneside were encouraged to become involved in the scheme and they helped to plant up the innovative new floating islands on the lake which will transform wildlife.

School pupils planting the floating islands (2019) – Courtesy of Esh Stantec

The pupils from West Moor Primary School, put on their gardening gloves to help bring life to Killingworth Lake for the final phase of the Killingworth and Longbenton flood reduction scheme. They also took the opportunity to learn about biodiversity with a talk from Biomatrix. As well as being an attractive addition to the lake, the islands will provide a natural habitat for wildlife and fish, as well as keep the lake clean and clear. A group of students from Northumbria University studying for an MSC in Safety, Health and Environmental Management were hosted at the site by Esh Stantec as part of community engagement. The Killingworth site will provide the basis for their ‘Environmental Management in Practice’ project.

Summary and conclusion

The new attenuation basin (May 2019) – Courtesy of Esh Stantec

Construction was substantially completed by the end of May 2019 within programme and budget. The photograph above shows the new attenuation basin with the new saplings planted just ahead of being seeded.

With the completion of the Phase 3 works at Killingworth Lake, Killingworth and Longbenton Scheme is now complete. By working in partnership, the team delivered a more suitable and sustainable solution with a greater level of flood protection to properties and wider benefits to the community than could be achieved as individual organisations.

Early community engagement proved successful in securing support for the scheme with wider benefits to be enjoyed by all.