SAVECO Environmental Limited

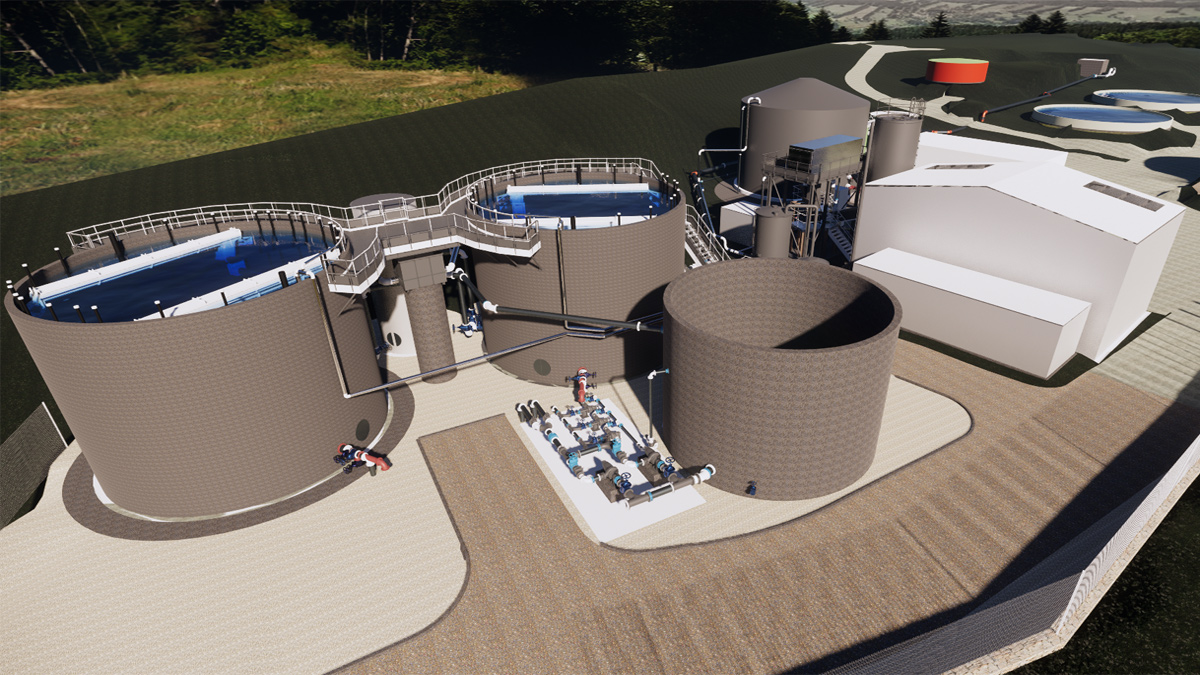

Grit Removal Travelling Bridges at Beckton STW

SAVECO Environmental Limited

The project scope includes:

- 3 (No.) travelling bridges (57 m long) supplied by SAVECO Environmental Limited

- 3 (No.) rotary lobe pumps supplied by Boerger LLC

- 3 (No.) level probes supplied by VEGA Level and Pressure

- 3 (No.) PLC control panels supplied by Te-Tech Process Solutions

How they work

PVD grease and grit removal travelling bridges are used to remove grease and grit from rectangular tanks in both municipal and industrial wastewater treatment plants.

The travelling ridges consist of a movable truck lying on two traction trolleys. One surface scraper and one bottom scraper are installed underneath the truck. The bridge is operated by a central gearbox connected to trolley drive wheels.

The tank is divided in two main parts: one for grit settling, the other one for grease collection. An air injection system installed inside the grit channel generates a circular movement, thus separating organic and floating particles from the grit. By this movement scum is conveyed into the grease collecting channel, while grit continues to settle. The bridge travels back and forth.

Travelling one way, it conveys the settled grit into the grit collection hopper through the bottom scraper. Running in the opposite direction it collects scum and floating particles by means of a surface scraper. The scrapers are operated by one gear motor only.

Courtesy of SAVECO Environmental Limited

Features

- Available for up to 8m wide and 50m long tanks

- Grit removal device

- Scum removal device

- Festooned cables

- Control panel

- Hot dip-galvanised carbon steel / 304 L / 316 L SS

Benefits

- Quick installation

- High efficiency grit and grease removal

- Easy installation even into existing tanks

Options

- Cable holding chain

Courtesy of SAVECO Environmental Limited

For more information contact SAVECO Environmental Ltd | +44 (0)1684 299104 | https://saveco-water.co.uk