Hydro International

Greenham Common STW

Greenham Common STW MNSS Combined Screen

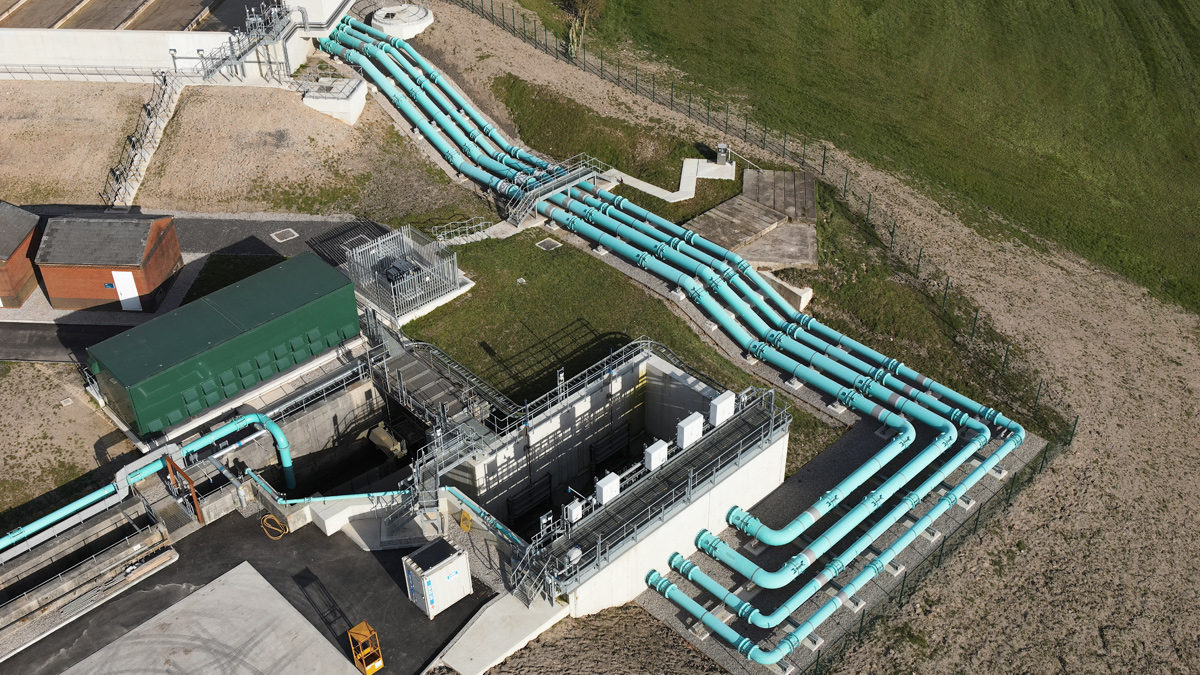

Thames Water’s Greenham Common Sewage Treatment Works (STW) is situated in the shadow of a former US Air Force base in Bishops Green, Newbury, and alongside the River Enborne. The untreated wastewater that Greenham Common receives has a high rag content and repeated screening carry over was affecting the full treatment process, the overall performance of the site and risked that the site would go out of environmental compliance.

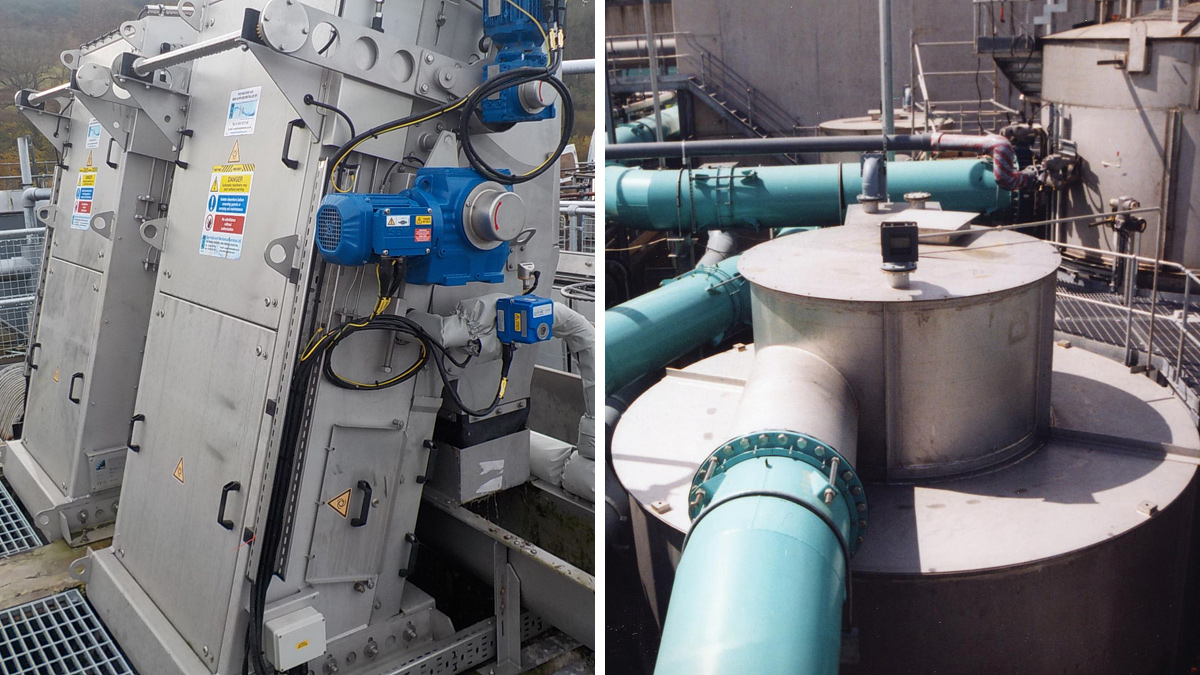

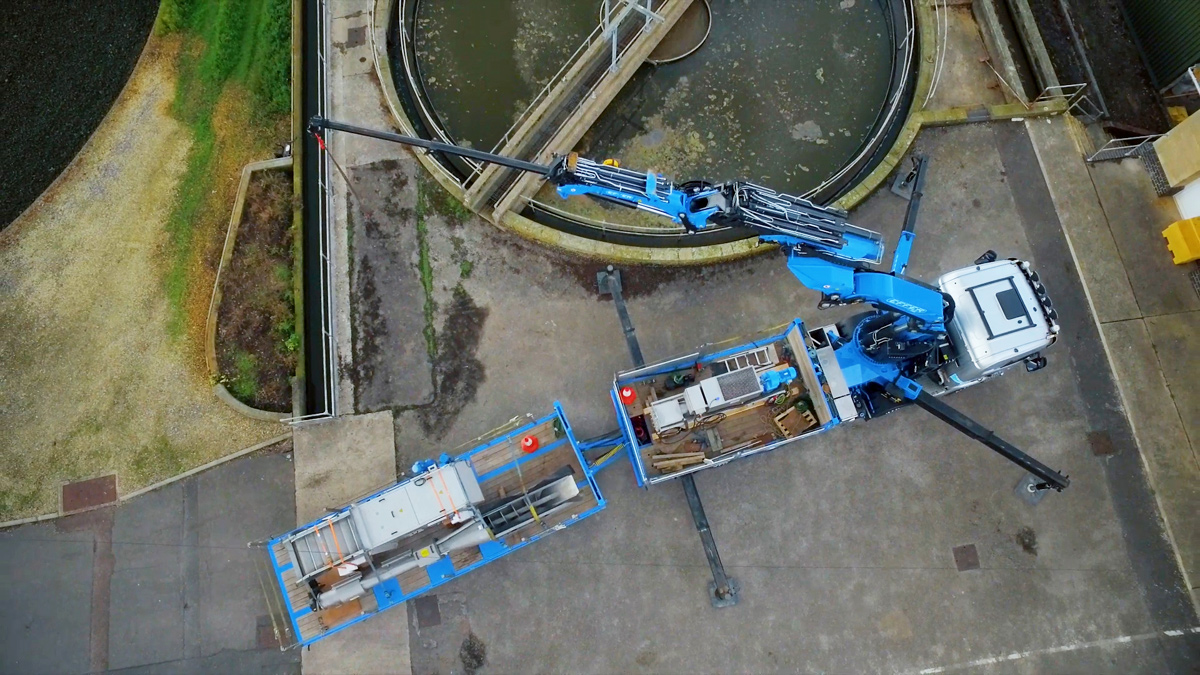

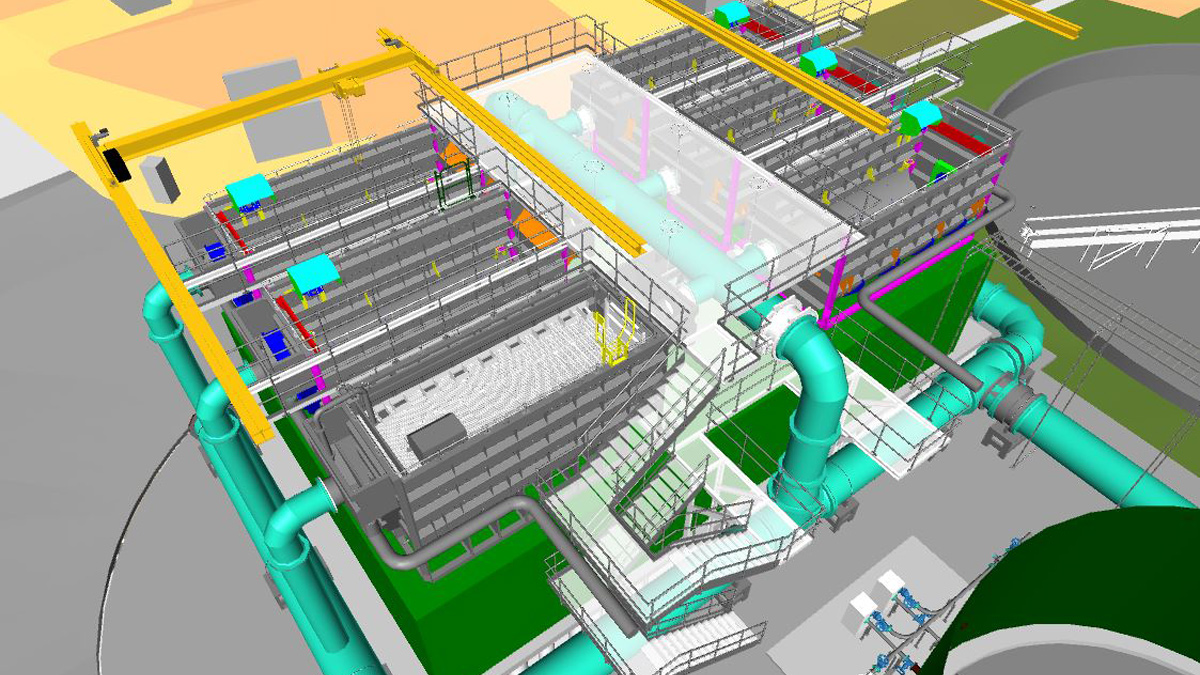

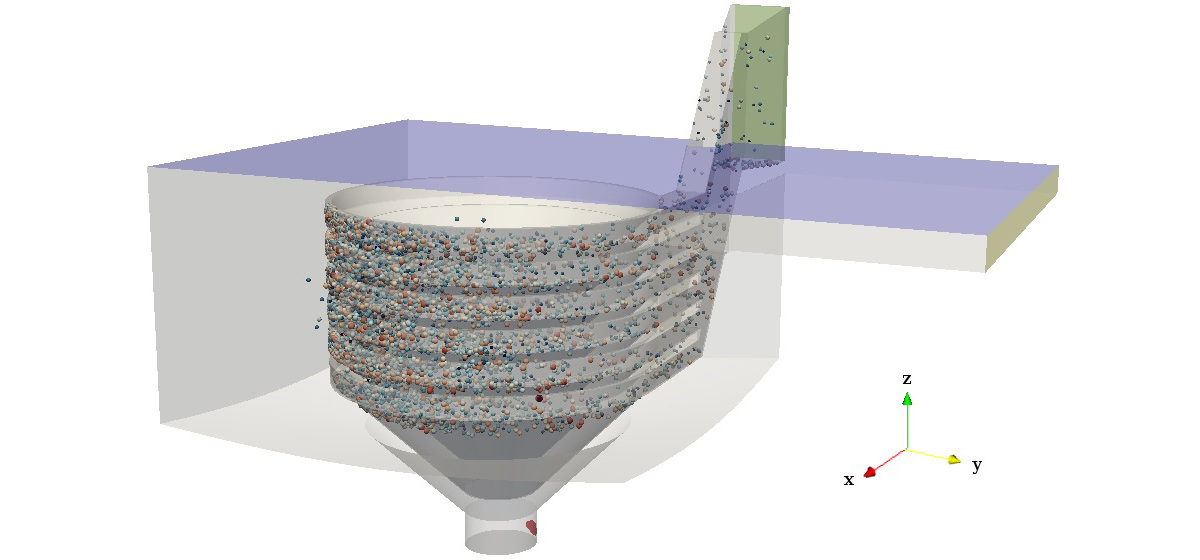

Thames Water approached Hydro International’s UK Wastewater Services team, M&N, to evaluate the site and propose a robust solution. The team installed the MNSS Combined Screen, to capture larger influent materials at the front end of the wastewater treatment process, protecting and improving the efficiency of the downstream treatment system.

Due to the site hydraulics/flows, there was no reliable wash water system for the MNSS Combined Screen, so the team found an innovative way to solve this. They created a bespoke system, including pumps, to use the effluent from the site’s primary settlement tank. The spray nozzles on the MNSS Combined Screen were also altered to accommodate the change.

Greenham Common STW MNSS Combined Screen

Simon Brum, Project Manager, Hydro International’s UK Wastewater Services Team, said:

“We needed to find a quick and effective solution for the Greenham Common STW to prevent any overflows, and designed and installed a robust, reliable inlet works system that combines screening, washing, transport, compaction and dewatering in a single cost-effective standalone solution.”

Henry Crompton, Lead Project Engineer at Thames Water Utilities Ltd, commented:

“We needed a suitable solution that was effective and within budget, and the team delivered that. We are very happy with the work undertaken on this site and will be using it as an example to our other Thames Water teams who may encounter the same issues.”

Handling flows of up to 150 l/s, the MNSS Combined Screen is designed for smaller plants and those facilities that require a more cost-effective screening solution – helping engineers, operators, and site owners to maintain treatment effectiveness even at remote and budget – constrained sites.

Greenham Common STW MNSS Combined Screen

Optimised for reduced maintenance and extended component lifetimes by the UK Wastewater Services team, only the MNSS Combined Screen achieves a screenings capture ratio of 53%, the highest of any independently tested 6mm combined screen.

To learn more about how our inlet works specialists can help you with your wastewater needs

M&N Electrical & Mechanical Services Ltd | +44 (0)1305 821142 | www.hydro-int.com/ukwws