Hydro International

Ground-breaking project leads to advanced wastewater grit removal system

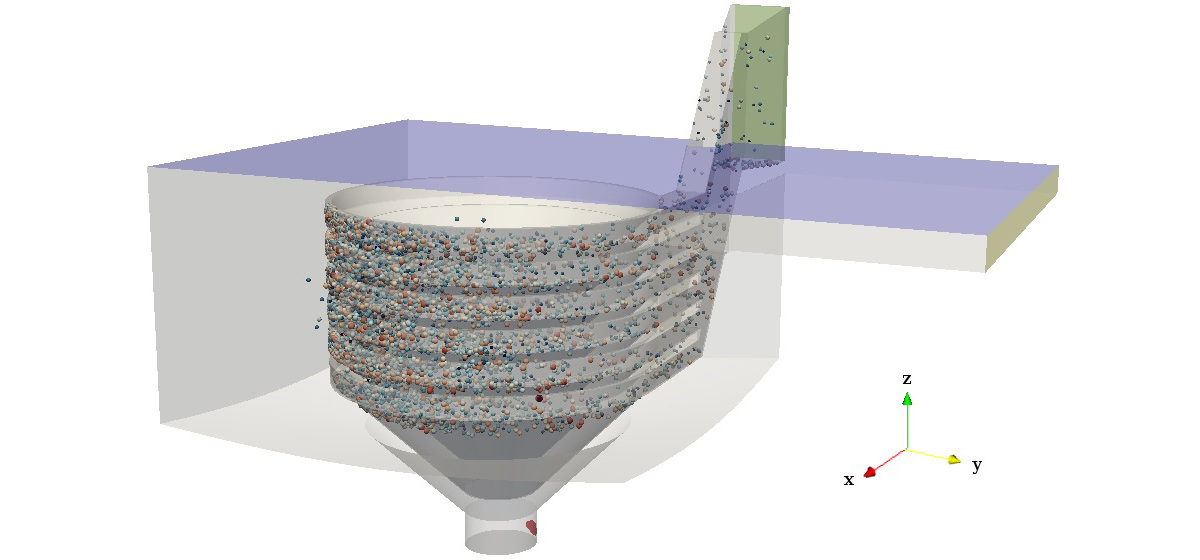

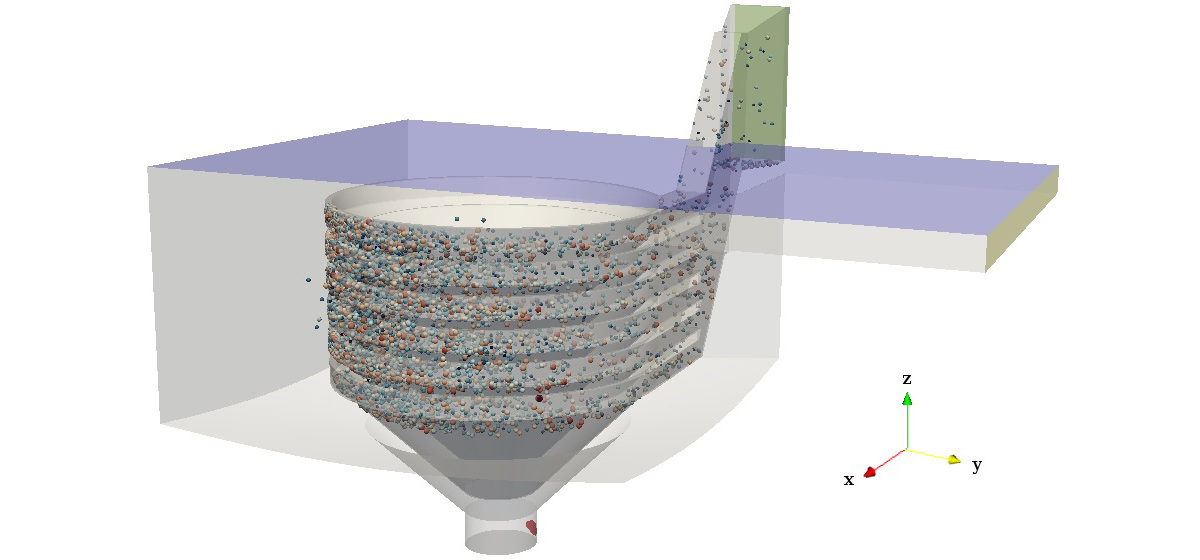

CFD model - Courtesy of Hydro International/University of Exeter

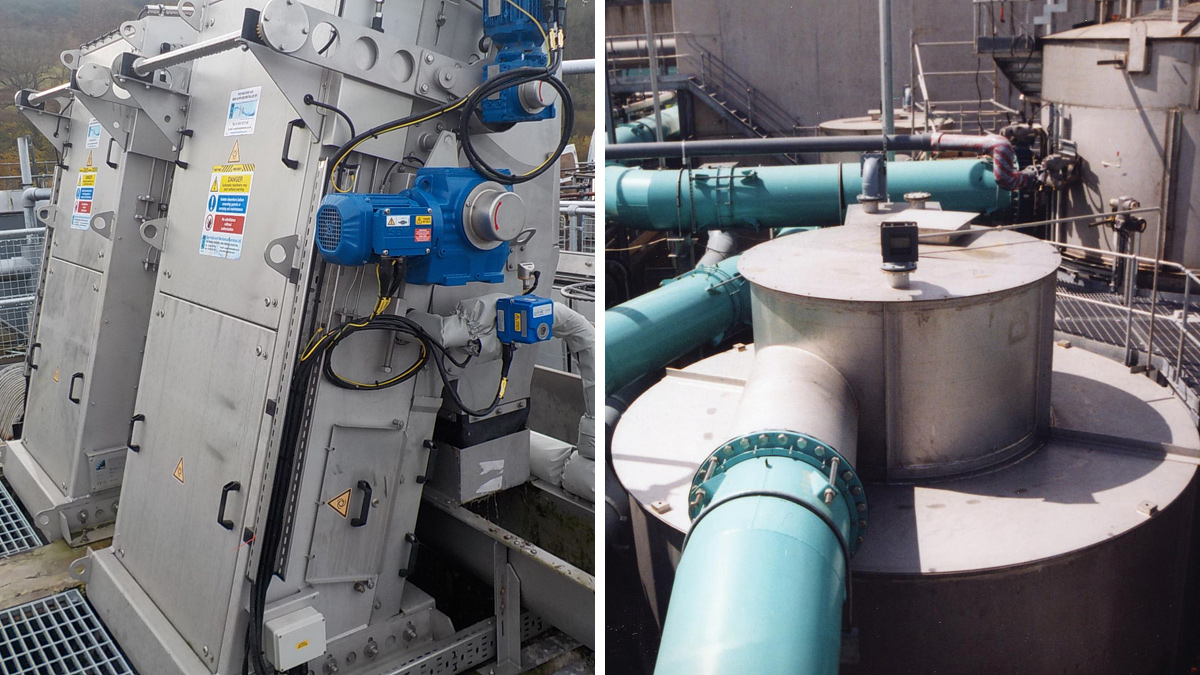

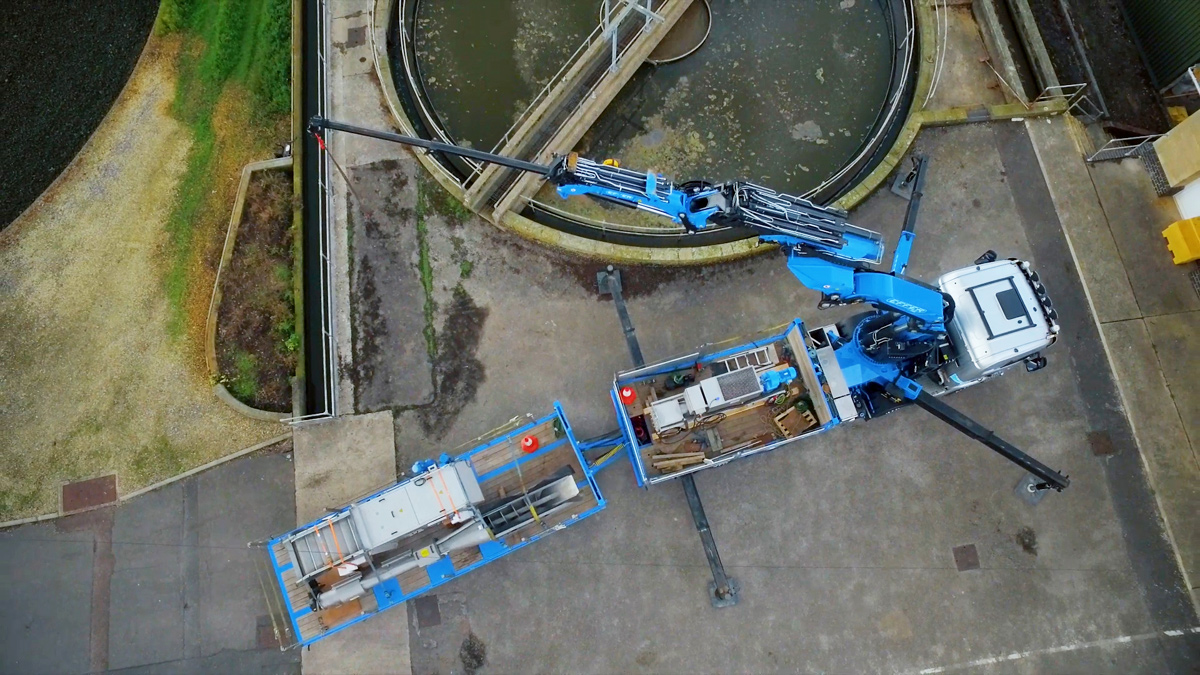

Suspended solids carried in water can cause a range of harmful effects in rivers, lakes and oceans, making the capture and removal of these solids critical for effective environmental protection. To address this problem, the project focused on optimising the stacked trays that remove high levels of suspended solids from wastewater.

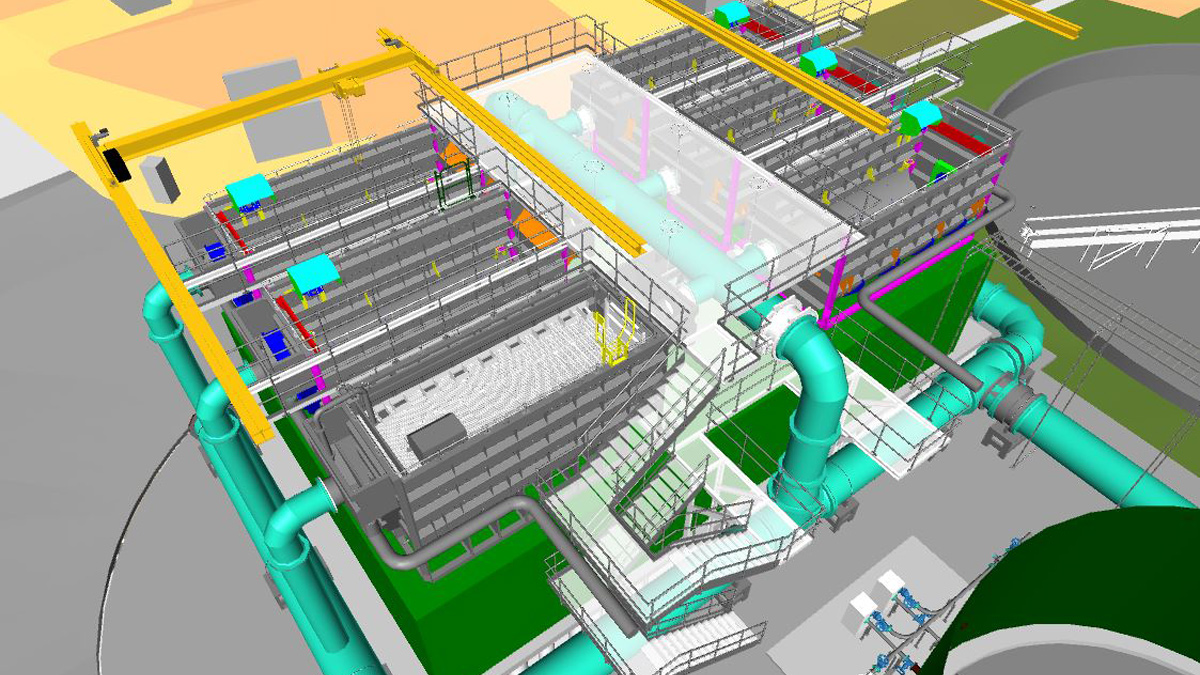

Combining optimisation methods and computational fluid dynamics (CFD), the project was able to derive new designs for hydrodynamic solids removal components that would have been difficult or impossible to achieve using traditional engineering methods.

The research was part of a Knowledge Transfer Partnership (KTP), supported by the UK government’s innovation body Innovate UK, which began in July 2019 and ran until September 2021. It builds on years of collaboration between Hydro International and the University of Exeter in the field of CFD.

The core of the project involved the optimisation of stacked trays that enable the removal of high levels of suspended solids in wastewater, with the primary objectives being to improve performance and reduce maintenance requirements. This was a complex, multi-objective, high-dimensional problem, so the team needed to adopt an unconventional approach in order to solve it.

To tackle the problem the project team coupled Bayesian optimisation techniques and CFD modelling, using a Bayesian optimisation toolset originally developed by the world-renowned Machine Learning Group at the University of Exeter. Bayesian optimisation was selected as it can be an order of magnitude more efficient than alternative approaches, such as genetic algorithms, on such complex design problems.

The Bayesian optimisation toolset was then connected to CFD simulations, allowing the team to use computing power to automate the design and evaluation process. The team ran the CFD simulations using supercomputers in Exeter and Bristol, with each optimisation run modelling some 300 designs at a time. This would have been impossible to achieve using other optimisation techniques. The team was one of the first in the world to use these techniques on new GW4 Isambard super-computing architectures.

The team subsequently corroborated simulation results through physical testing of prototypes in Hydro International’s hydraulics laboratory in Clevedon.

The outcome of the project was a new stacked tray design that improves grit removal performance and enables the production of more compact systems that can handle higher wastewater flows and requires less maintenance—an excellent example of combining academic research with commercial incentives to address real-world challenges.

Although the project was focused on improving technologies that will be applied to future iterations of the HeadCell® advanced grit removal system, the findings are fundamental to Hydro International’s core technologies, and will be applicable to other products that rely on the same hydrodynamic principles such as Downstream Defender® and First Defense®.

In addition, not only did the project apply methods for complex design optimisation already developed by the University of Exeter, but it also drove new developments in multi-objective optimisation and constraint handling, resulting in new advances in expertise and understanding.

Following completion of the project, Innovate UK assessed the KTP and awarded it a Grade A, or “Outstanding”.

Dan Jarman, Hydro International’s Group Technical Manager said:

“We have a long history of investing in new science and new technologies to help our customers, and this project continues that tradition. This is the first time that Bayesian optimisation and CFD techniques have been applied in the water sector, which represents a significant step forward in product design excellence. In a sector that has been unfairly criticised for being slow to adopt new technologies and techniques, we’ve shown that there are teams out there willing to push boundaries in order to benefit utilities, consumers and the environment.”

Jonathan Fieldsend, Professor in Computational Intelligence at the University of Exeter said:

“This project is an excellent example of what can be achieved when a KTP involves such a wide range of talent and experience. To achieve its outcome, it has needed academics from the Computer Science and Engineering departments, specialists from industry, and support from a highly-skilled impact and business team. It has delivered significant enhancements for an important Hydro International product – in the crucial area of wastewater management – and has also led to advances in applied optimisation techniques and algorithms which have use more broadly in CFD-driven design.”

About Hydro International

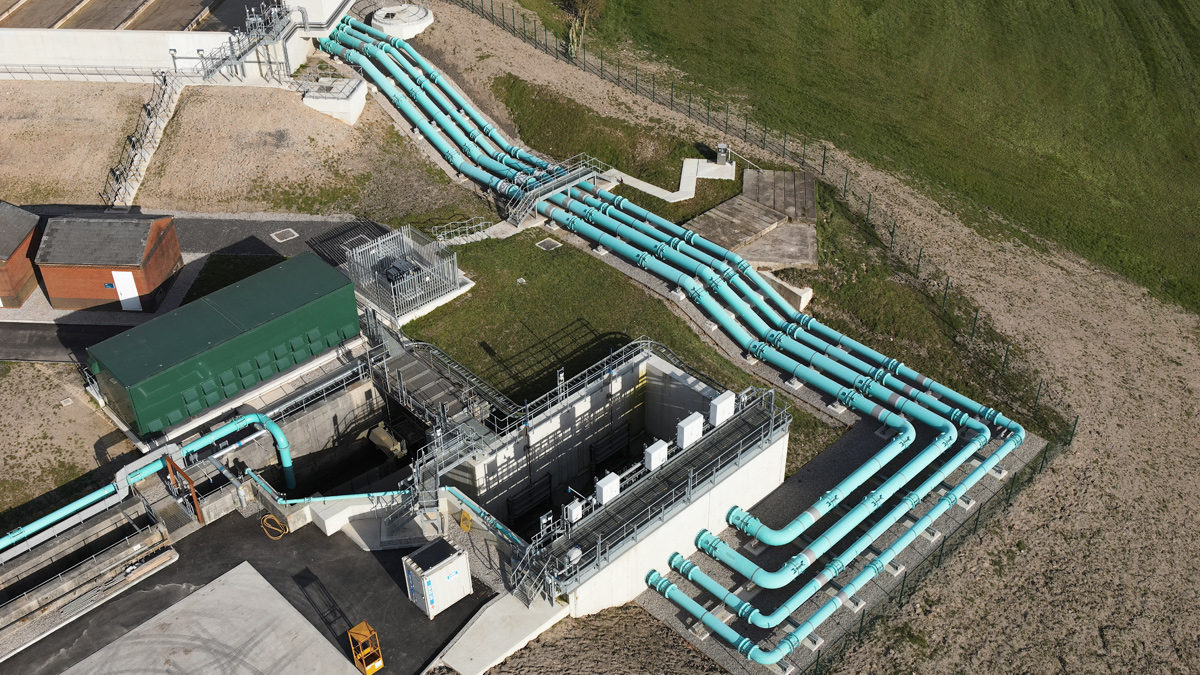

Hydro International is a global company that provides advanced products, services and expertise to help municipal, industrial and construction customers to improve their water management processes, increase operational performance and reduce environmental impact.

With over 40 years of experience and a reputation for engineering excellence, businesses and public organisations all over the world rely on Hydro International products and services to reduce flood risk, improve water treatment and protect the environment from water pollution.

Headquartered in Clevedon, UK, Hydro International has a network of over 80 distribution partners and serves customers in more than 40 countries.

About the University of Exeter

The University of Exeter combines world-class research with excellent student satisfaction, ranking in the Top 150 of the THE and QS World University Rankings. We are one of the very few universities to be both a member of the Russell Group and have a Gold award from the Teaching Excellence Framework (TEF), evidencing our international reputation for excellence in teaching and research.

Each year, the University of Exeter delivers over 1500 projects with industry and generates over £52m from this work. We believe impact is about making a difference, and our world-class researchers have an excellent track record in making valuable contributions to our society, economy and the environment.

Our dedicated KTP team – based at the University’s Innovation, Impact and Business directorate – is the leading Knowledge Base partner in South West England and has successfully delivered over 100 KTP projects to date, with 85% of these rated good to outstanding.

To learn more about how our inlet works specialists can help you with your wastewater needs

M&N Electrical & mechanical Services Ltd | +44 (0)1305 821142 | www.hydro-int.com/ukwws