National Trench Safety UK

Double Slide Rail Installation at SmartParc Development, Derby

Strut removal as part of NTS UK's tie-back installation - Courtesy of NTS UK Ltd

NTS UK were first contacted by KPM Contracting in February 2023 with regards to providing a ground support system for a 13m x 3m foul pump tank to be installed at 5.5m below ground level. NTS UK provided a ground support system utilizing their Double Slide Rail tie-back system to provide a clear internal opening of 14.2m x 4.2m. Since the successful installation of the first foul pump tank NTS UK have gone on to provide the ground support solutions for an additional nine tank installations undertaken by KPM across the site. These excavations ranged from double tank installations at 20m x 15m plan dimensions to manhole installations 3.5m x 3.5m in plan with incoming services on three sides accommodated by the NTS UK pile chamber solution.

The ground support systems utilized at the site incurred a number of challenges including high and variable groundwater, varying ground conditions, tight programme, unknown existing infrastructure and the neighbouring River Derwent. NTS UK were able to provide a design solution using their Slide Rail System.

Many of the tank excavations were designed to allow for the re-use of components between different excavations, cutting down on transport, therefore reducing the carbon footprint attributed to each excavation. Fewer components than traditional shoring systems are used with the NTS UK Slide Rail system, this ensures fewer lifting operations and a much quicker and safer installation method. The system was installed using the dig & push method of installation which allows for no eccentric vibration and a no-toe solution, ensuring the risk of impacting any unknown services was mitigated.

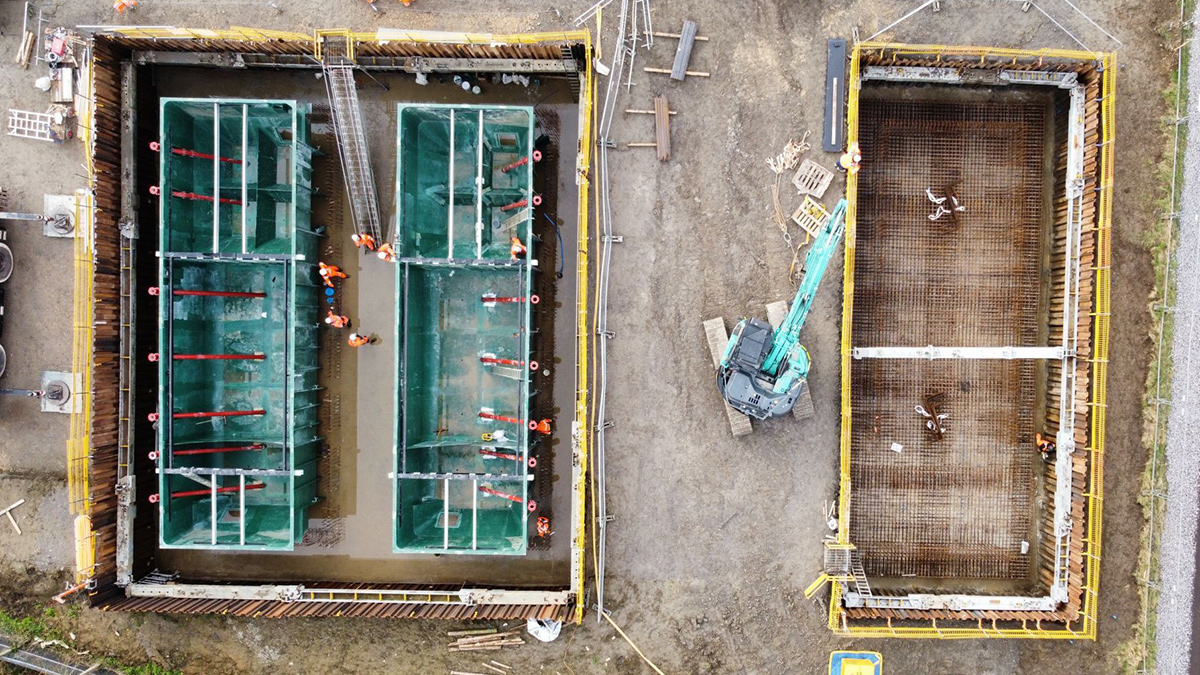

(left) First tank being lifted into the open excavation and (right) twin tank Slide Rail excavation 20m x 15m x 4.5m – Courtesy of NTS UK Ltd

One of the larger 20m x 5m x 4.5m excavations at the site was close enough to the River Derwent for a sheet and frame solution to be considered. NTS UK’s temporary works designers deemed that an excavation this size at the site required 85 (No.) 7m Long Larssen Piles with two levels of the NTS UK System 80 frame. In contrast the NTS UK Slide Rail System utilized for the construction of the ground support system consisted of fewer than 50 components. The absence of any frames has also resulted in concrete/material, and therefore environmental and cost, savings for KPM Contracting. The components from this excavation were then utilized on two other excavations at the site. KPM Contracting were able to excavate, install & backfill the 20m x 5m x 4.5m excavation in seven working days – far quicker than would have been possible when using traditional methods, highlighting the environmental & commercial benefits of the system.

NTS UK’s Slide Rail is becoming ever popular in temporary works circles as the preferred method for fast, safe, cost-effective temporary excavation solutions.

Martin Munnelly, director of KPM Contracting.

“The system is so easy to use, far quicker, much safer and reduces our material costs significantly. It will definitely be explored for all future excavations,”

Geoff Bates, Area Sales Manager NTS UK.

“The guys on site have been brilliant, and have all fully embraced the system.”

For more information contact National Trench Safety: 03332 076 007 | https://www.ntsafety.co.uk/