Trant Engineering Ltd

Sandown WSW

Trant Engineering Ltd

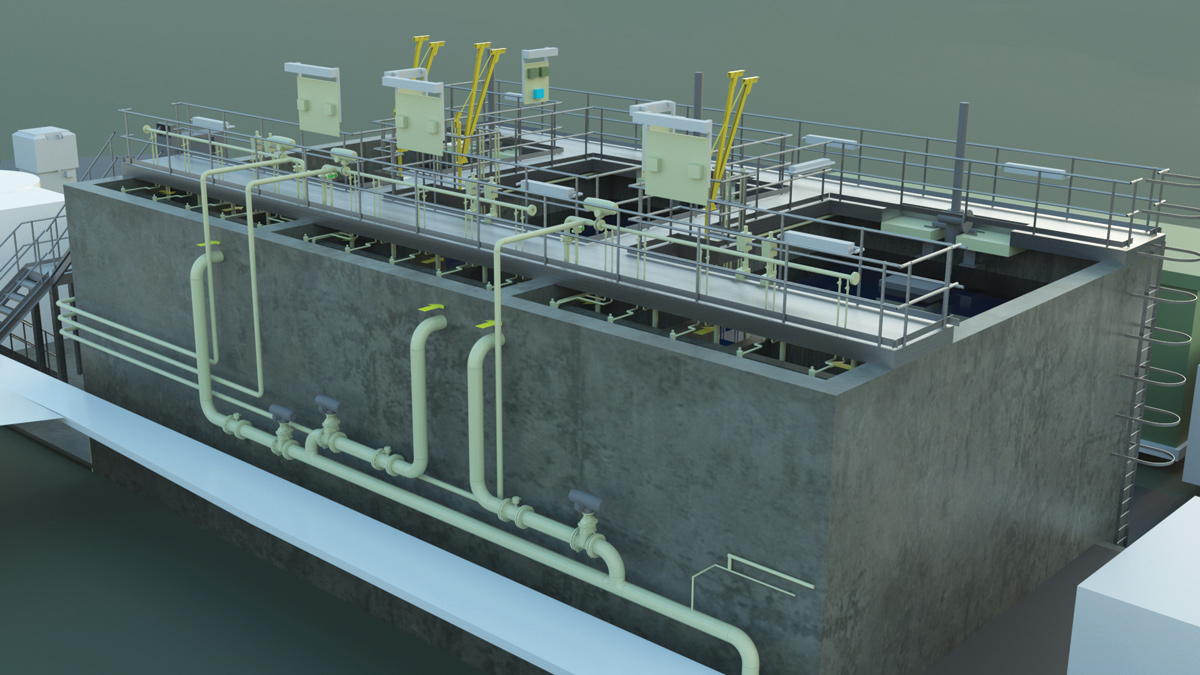

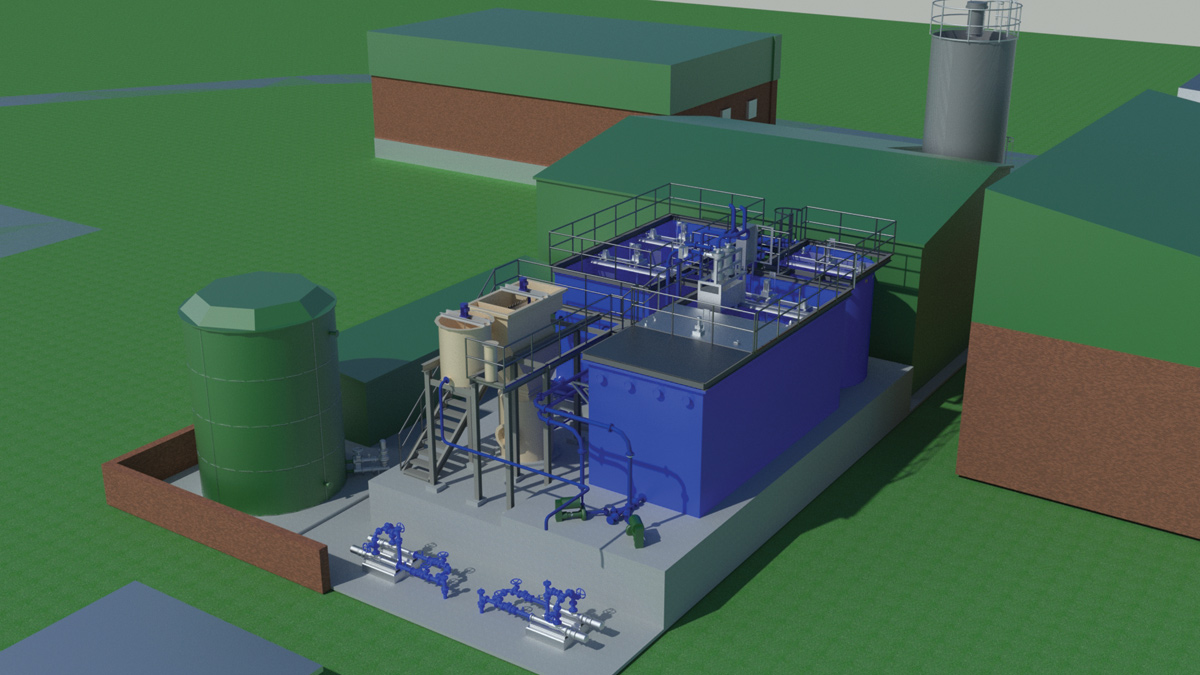

Southern Water’s Sandown Water Supply Works is located on the south-east of the Isle of Wight and supplies drinking water to Sandown and Shanklin. The average winter demand of 7.7 Ml/d can almost double up to 13 Ml/d in the summer due to tourism. Southern Water’s Asset Strategy requires a reliable supply of 12 Ml/d of treated water from the works. A risk assessment to establish resilience of the works’ infrastructure identified the ageing clear water tank and high lift pumping station as potential weaknesses which could affect supply. Southern Water awarded Trant Engineering a £10m design and construct contract, Phase 1 for the replacement of these assets. Phase 2 of the project works is for improvement of wash water discharge and flood resilience on site, and Phase 3 includes installation of new caustic soda offloading and storage facilities together with new dosing equipment installed in a new GRP kiosk.

The story so far

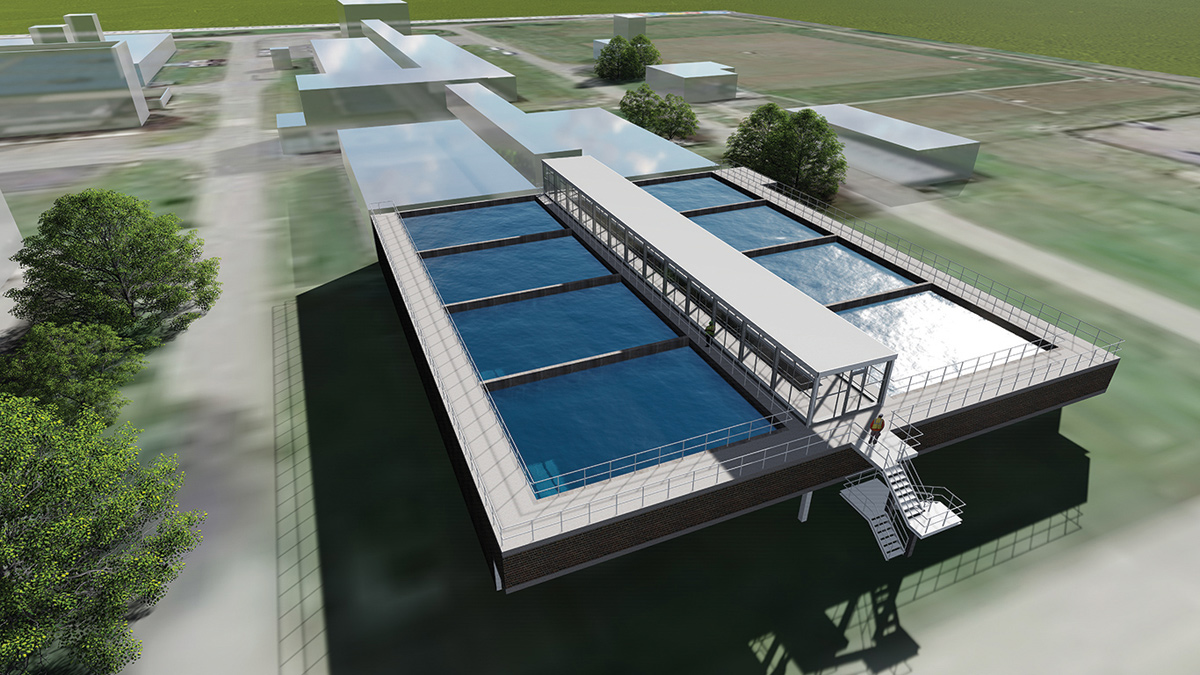

The new Phase 1 high lift pumping station will deliver up to 8 Ml/d to Shanklin Service Reservoir and up to 14 Ml/d to Brading Service Reservoir via existing ultraviolet reactors along with the power supply and motor control centre (MCC2). The contract also covers extensive pipework modifications and the installation of new supply flow meters, treated water aluminium monitoring and triple validated contact tank outlet chlorine residual monitoring.

Prior to commencing on site, Trant undertook a series of surveys and investigations which identified a number of construction challenges. In addition to the requirement to keep the works in operation during the work, the site is located within an AONB, which required planning permission and environmental mitigations being satisfied for limited environmental impacts. Due to site space constraints and the need to cut down disruption to live treatment plant, Trant identified early on that the need to build the new equipment offline as far as possible and to provide a new incoming power supply, so that the new equipment could be powered up and tested independently of the existing works.

The new glass-coated steel sectional clear water tanks – Courtesy of Trant Engineering

Innovative design

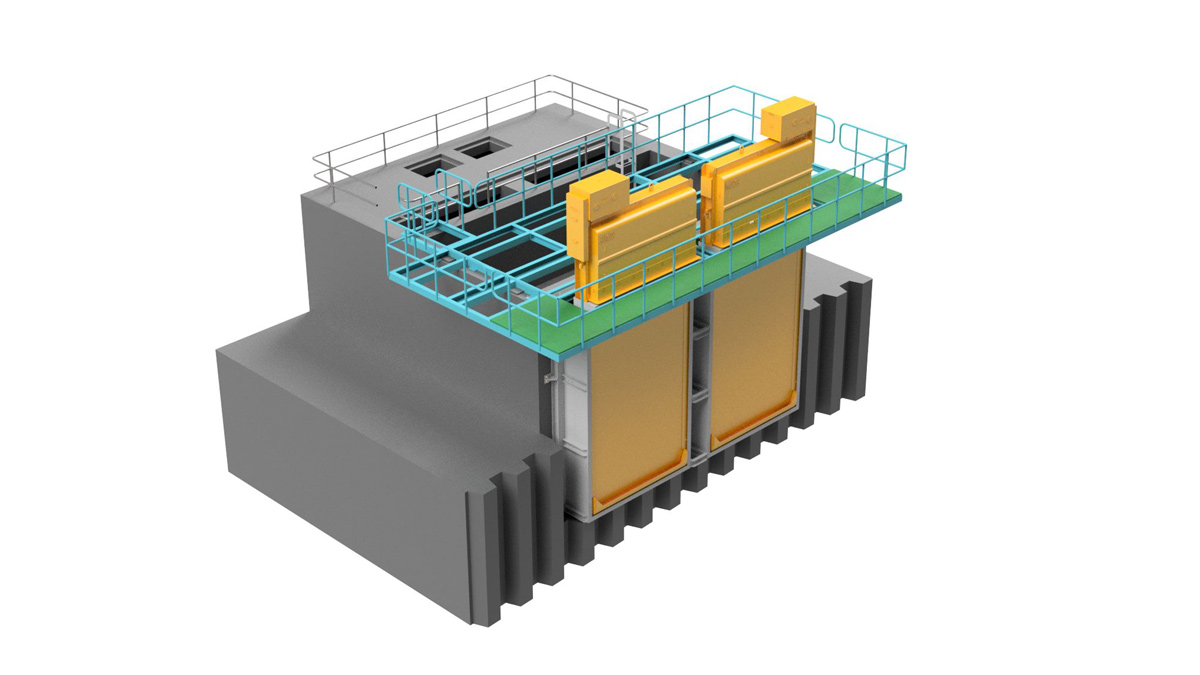

To reduce excavation work, Trant proposed a design using two new glass-coated steel sectional clear water tanks, 6m diameter and 7m high, constructed above ground on a brownfield area of the site. The tanks feed two sets of five, vertical multistage pumps, one set for Brading and one for Shanklin, installed above ground mounted on concrete plinths, with a surrounding steel access platform with staircase at either end. Due to the level of the outlet of the contact tank being below ground, an intermediate ‘re-lift’ pump station was introduced to feed the clear water tanks. The re-lift pumping station used a jacketed shaft construction method to avoid heavy temporary works.

Southern Water’s Senior Project Manager, Kev Fausset said:

“Trant was very pro-active in proposing innovative designs to minimise below-ground works and build off line for least disruption to live process works. That has helped to maintain supply and reduce the overall programme of works.”

Inside one of the new glass-coated steel sectional clear water tanks – Courtesy of Trant Engineering

Looking forward

Trant started on site in September 2023 and the scheme has made a great start with significant progress on the civil construction works. However, a high volume of complex works remains to be delivered on the scheme within what is a challenging programme and site environment.

Tony Jacobson, Trant’s Senior Project Manager said:

“Success will be achieved through ongoing collaboration with our client, supply chain and the wider water industry. The new clearwater tanks will be installed during the summer and the new MCC and electrical work will be completed in time for the arrival of the new pumps in the last quarter of 2024. Simultaneously, we are progressing the mechanical and electrical works for Phases 2 and 3 so that the project delivers on all its objectives and provides an excellent standard of new and upgraded assets.”

For more information: Trant Engineering Ltd | +4423 8066 5544 | www.trant.co.uk |

New MCC kiosk - Courtesy of Trant Engineering