SMR Projects Ltd – Xypex UK Distribution

College Avenue Contact Tank

Courtesy of SMR Projects Ltd - Xypex UK Distributors

The challenge

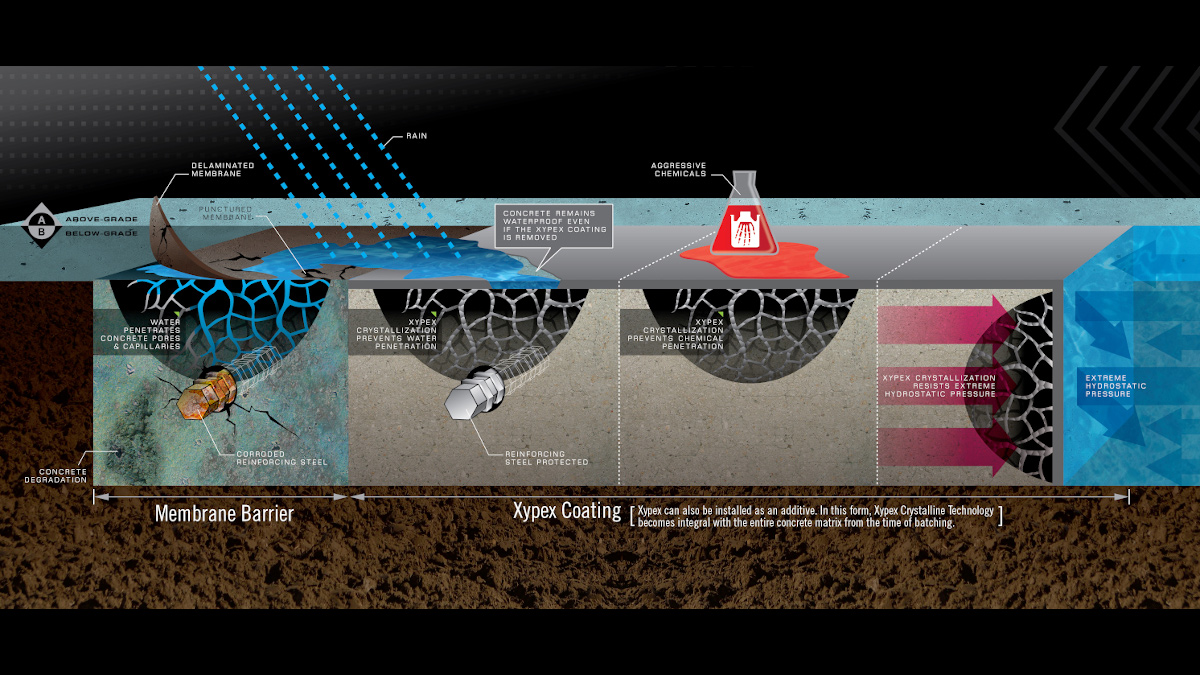

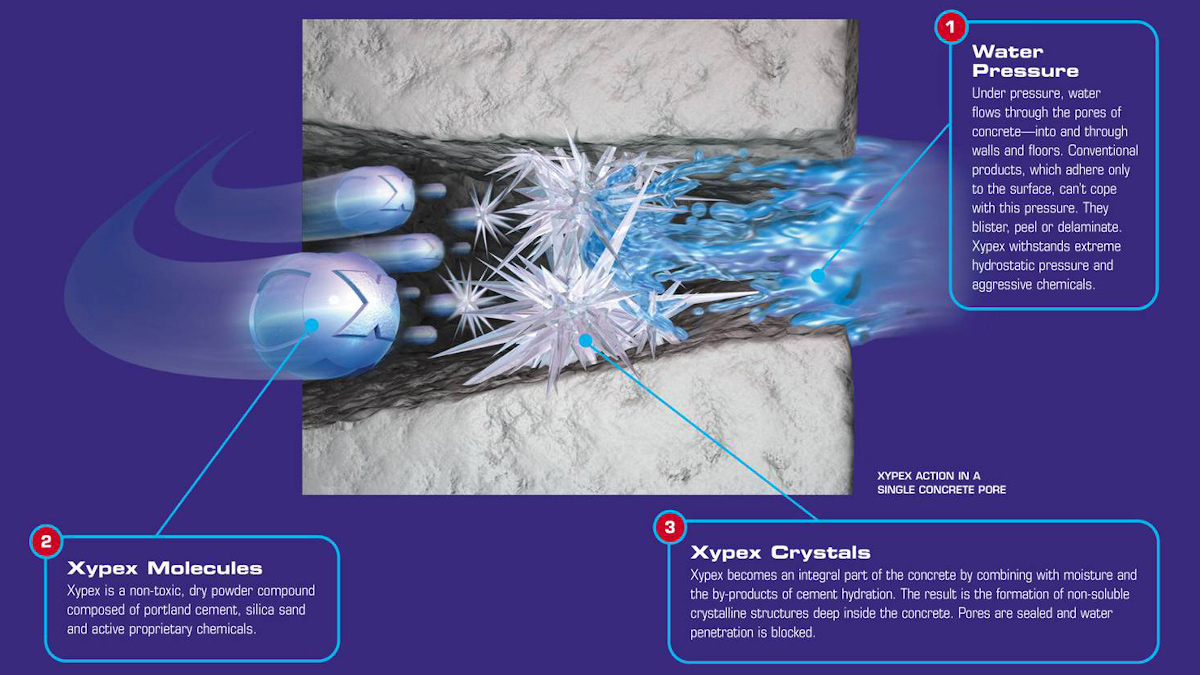

The South East Water contact tank has a constant output of 18.1 million litres per day, it contains water which is treated with Sodium Tripolyphosphate and sodium hypochlorite before entering the distribution network. The structure is of a ‘certain’ age and has a number of active leaks that have progressively worsened over time. As the tank is in constant use, it cannot be taken off-line and so a solution was required which could be undertaken against heavy flow of water with the tank still in use.

The Xypex solution

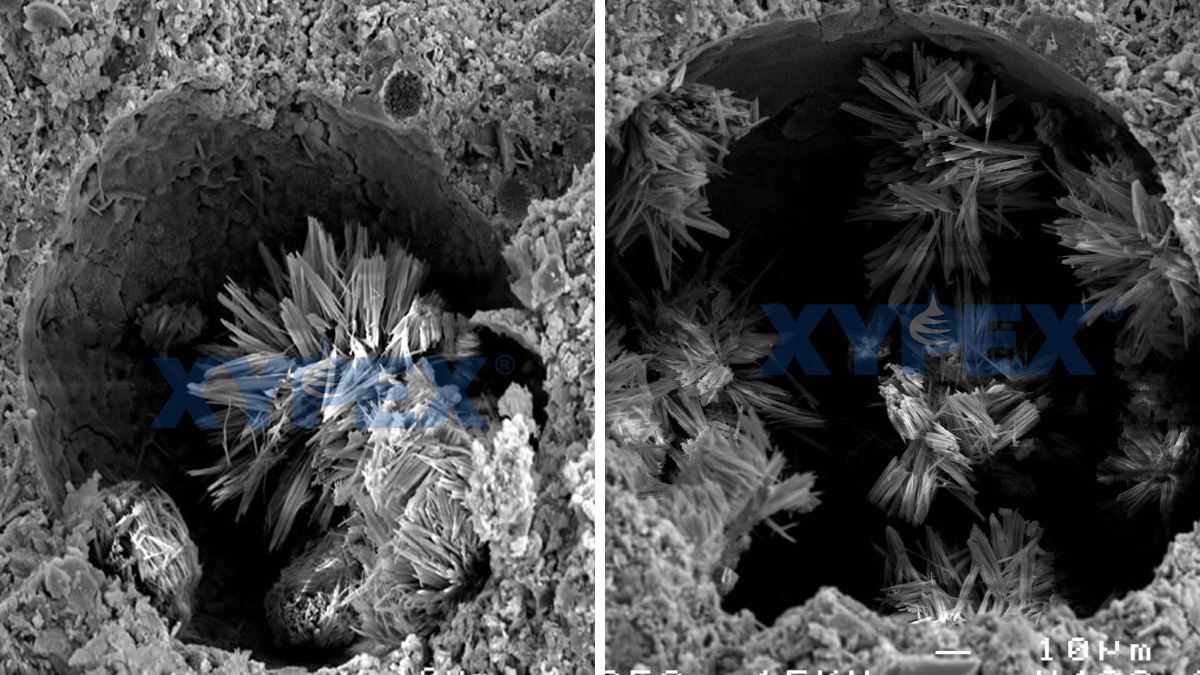

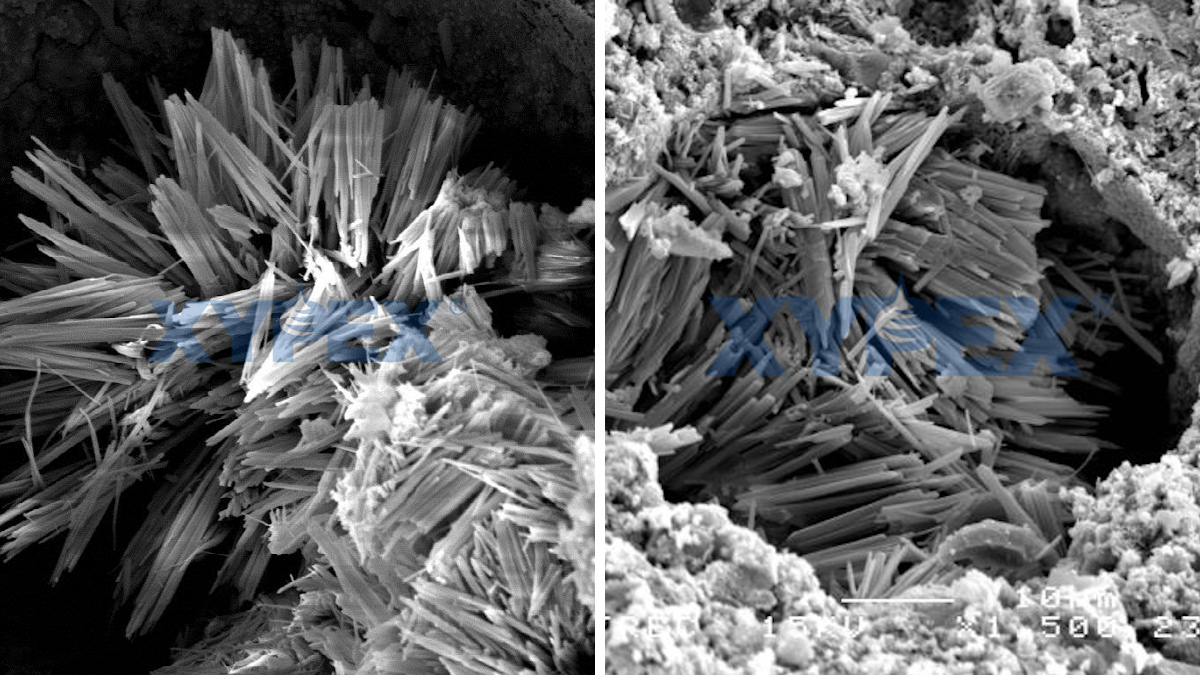

Xypex not only likes water, but the repair method requires a wet environment therefore an active leaking tank is not a problem. The cracks were chased out in accordance with the DWI Reg. 31 approved Instructions for Use Document i.e. a minimum of 37mm depth and 25mm wide, following the line of the crack. Either side of the crack was cleaned and the laitance removed to expose the capillary and pore network.

The Xypex solution; Concentrate and Patch’n Plug – Courtesy of SMR Projects Ltd – Xypex UK Distributors

A bleed pipe was installed and secured with Xypex Patch’n Plug at the lowest point of the crack where water flow was at its greatest. Then the base of the crack was plugged using Xypex Patch’n Plug to stop the flow of water. This was then left to see if there were any additional issues that manifested themselves over night. Once the flow was proven to have stopped, the repair was finished using Xypex Concentrate both as a dry pack and a slurry in line with the IFU and Xypex’s standard repair methodology.

The results

The Xypex methodology using Xypex Patch’n Plug stopped the flow of water instantly and allowed the repair to be undertaken. The crystalline chemistry within the Xypex Concentrate will migrate deep in to the concrete matrix around the repair, driving water out and increasing the life and durability of the tank in those areas.

Courtesy of SMR Projects Ltd – Xypex UK Distributors

As the original repairs were undertaken, additional pressure was transferred to other cracks that were visible, but not leaking, and these were all repaired using the same method.

In all, only 2 materials were used on site and no specialist methods were used. SMR Projects Ltd attended and were on hand for technical help throughout the installation.

For more information: SMR Projects Ltd – XYPEX UK Distributors: +44 (0)1295 279747 | www.smrxypex.co.uk