SMR Projects Ltd – Xypex UK Distribution

Thames Tideway Tunnel – West Section

Courtesy of SMR Projects Ltd - Xypex UK Distributors

The waterproofing challenge

Thames Tideway is London’s new “super sewer” which will run from Acton to Beckton and prevent millions of tonnes of pollution reaching the River Thames. The West Section is being It is constructed by the joint venture between BAM, Morgan Sindall and Balfour Beatty.

During the design phase, technical discussions were held between SMR Projects and the JV designers Morgan Sindall Underground Professional Services to explore how Xypex’s crystalline technology could assist in reducing the permeability of the concrete. This was especially important across the construction joints.

Trials were undertaken in conjunction with a ready mix company to establish how the crystalline technology behaved within the very specific mix design. In addition this was to prove its water tightness over standard tunnel construction methods. A number of trials were set up with and without Xypex products for a clear comparison.

Successful trials

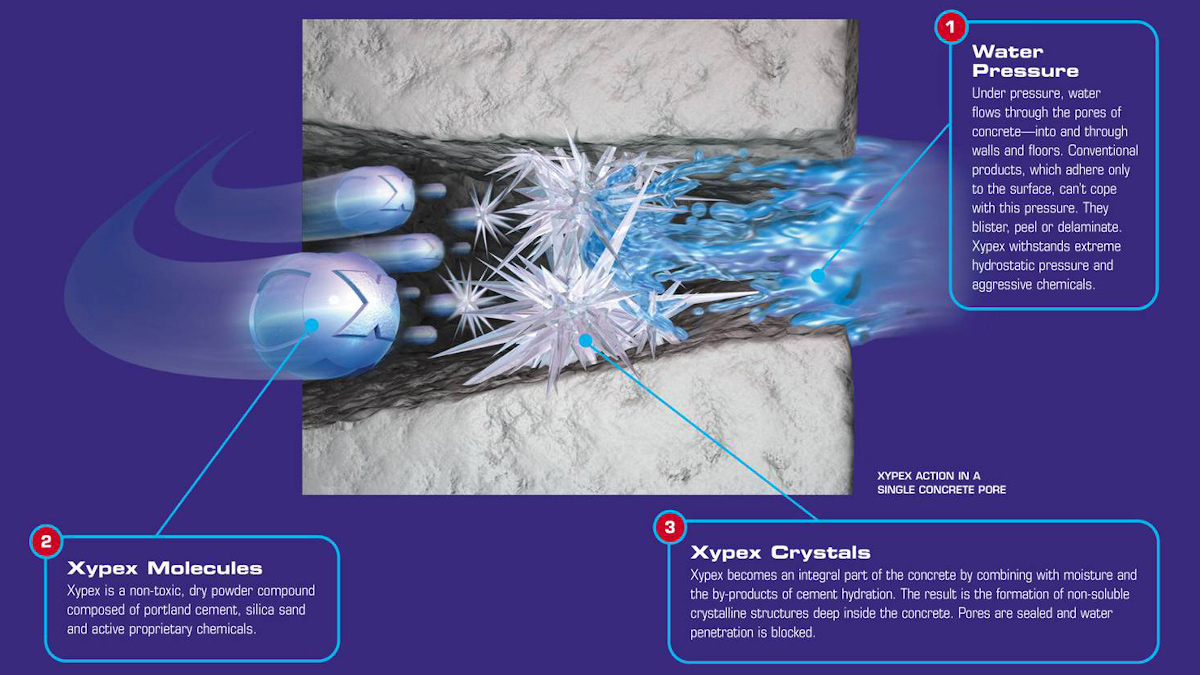

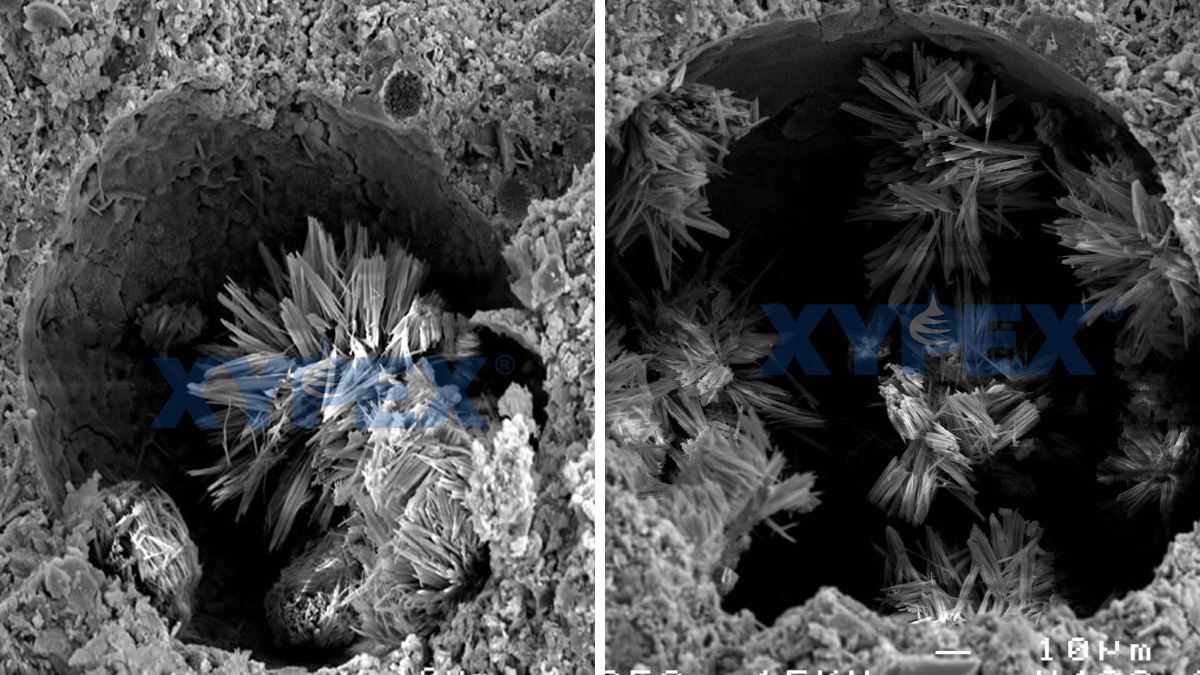

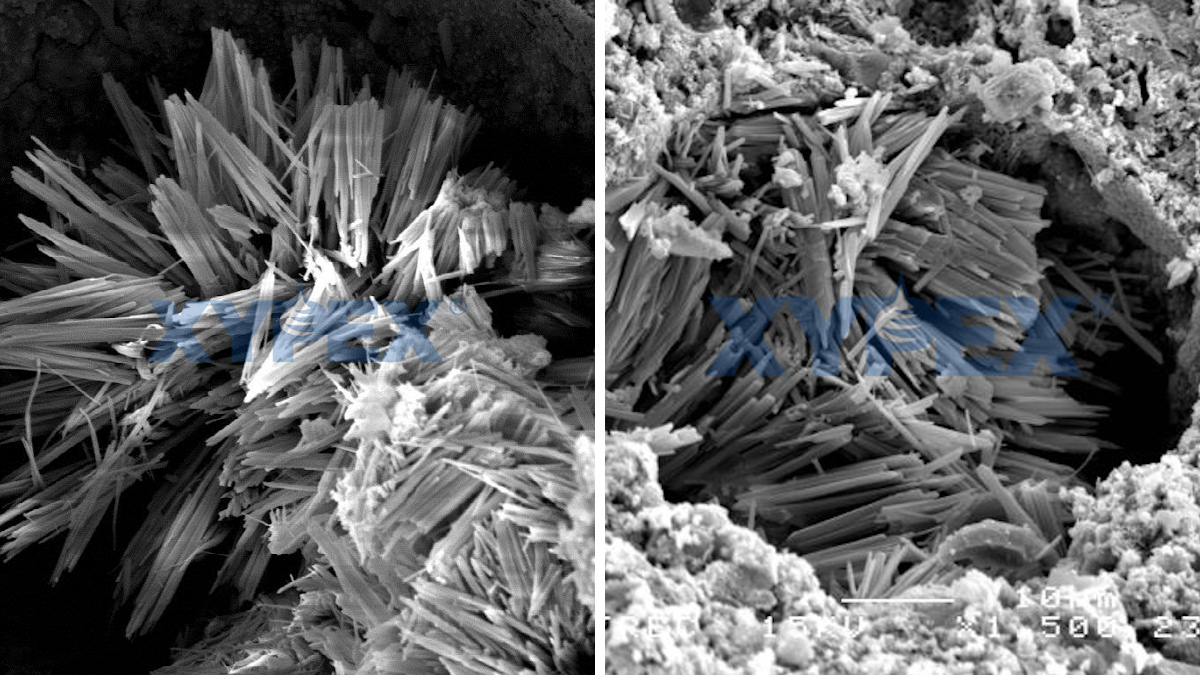

The trial results proved that the addition of Xypex C-Series Admix to the concrete gave the greatest protection against permeability. The growth of the crystals across the joint gave a seal in excess of what was thought possible. When tested across the 45 degree “day” joint, cores were taken through the joint in 3 axis to test for water permeability and the results were more than enough to confirm that this technology was superior.

Courtesy of SMR Projects Ltd – Xypex UK Distributors

Change of design

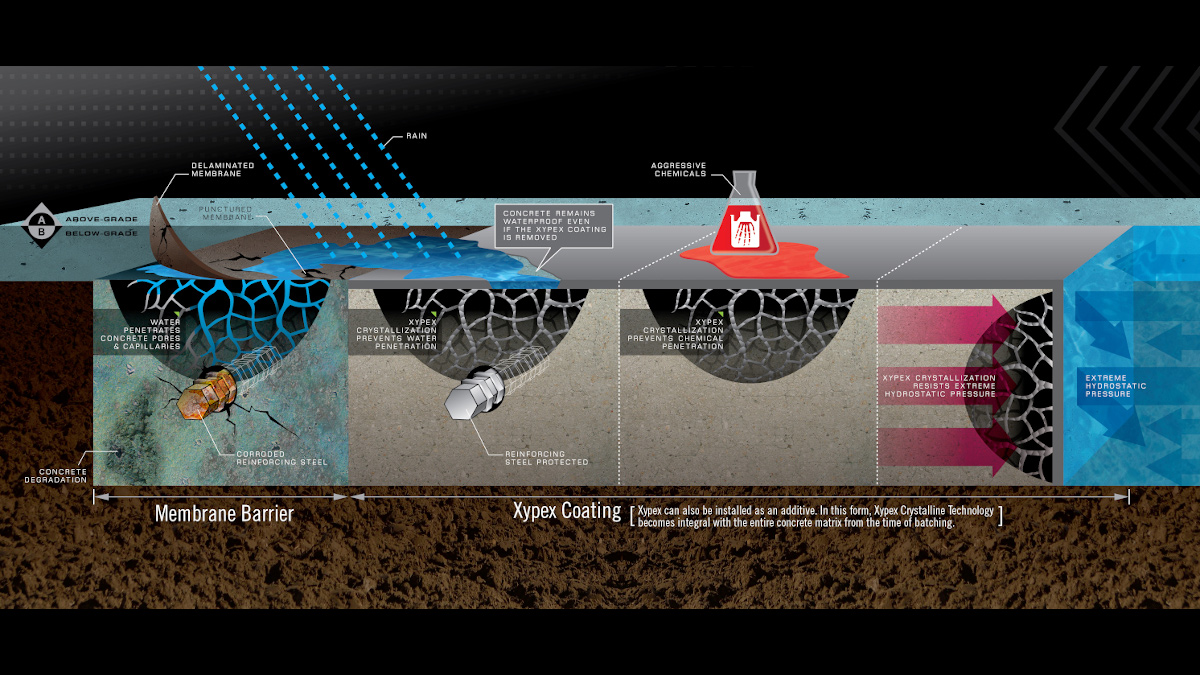

The western section was originally planned to be constructed using a sprayed concrete primary liner and a cast in situ secondary liner with a waterproof membrane placed in between the two layers.

The addition of Xypex C-Series Admix meant that, following the trials, the stakeholders were satisfied enough to remove the membrane in the Hammersmith connection tunnel. The proven benefits of using Xypex C-Series Admix lead to its use throughout the whole of the Western Section.

Added benefits of Xypex

The Xypex C-Series Admix waterproofed the concrete and the joints during the hydration period of the concrete. It also provided additional benefits over and above non-active pore blocking admixtures by having the ability of self-heal cracks up to 0.4mm.

Furthermore, microbial induced corrosion is common to sewage collection and wastewater treatment structures. It’s a challenge well known to engineers as they address the ever-increasing requirement for structures that will meet the growing demands of industry, the environment, economics, and the need for improved water supply and sanitation.

Xypex is proven in new sewage and wastewater treatment structures. It is excellent at handling chemical attack in severe biochemical conditions.

The Xypex solution; Xypex C-Series Admix – Courtesy of SMR Projects Ltd – Xypex UK Distributors

The final specification

SMR Projects supplied 100,000 kilograms of Xypex C-Series Admix. This was used on the primary liner incorporated within the sprayed concrete, awaiting the secondary liner to be cast directly against it.

For more information: SMR Projects Ltd – XYPEX UK Distributors: +44 (0)1295 279747 | www.smrxypex.co.uk