Bürkert Fluid Control Systems

Raising the Standard of Iron Measurement in Water Quality Analysis

The Type 8905, equipped with the MS06 iron sensor, offers the opportunity to monitor water quality automatically in both open and closed loop applications and ensure chemical dosing and filtration processes are operating as required

There are numerous parameters that need to be monitored and accuracy as well as repeatability are crucial for operators’ confidence. Bürkert’s compact, modular water quality analysis solution offers an automated process that delivers precision monitoring for a wide variety of applications.

Water is a vital resource, not only for basic living, but also in industrial settings, where it is used for manufacturing, power generation and throughout the food and beverage market. As such, the quality of the water can directly affect product quality, so regular sampling and testing is essential to ensure any remedial actions are taken promptly.

Water quality monitoring can take many forms, from the most basic manual sampling and testing to large-scale automated systems, but in every case, accuracy and repeatability are crucial. Improvements can be achieved by increasing the frequency of testing, calibrating sensors regularly and benchmarking results.

Modular simplicity

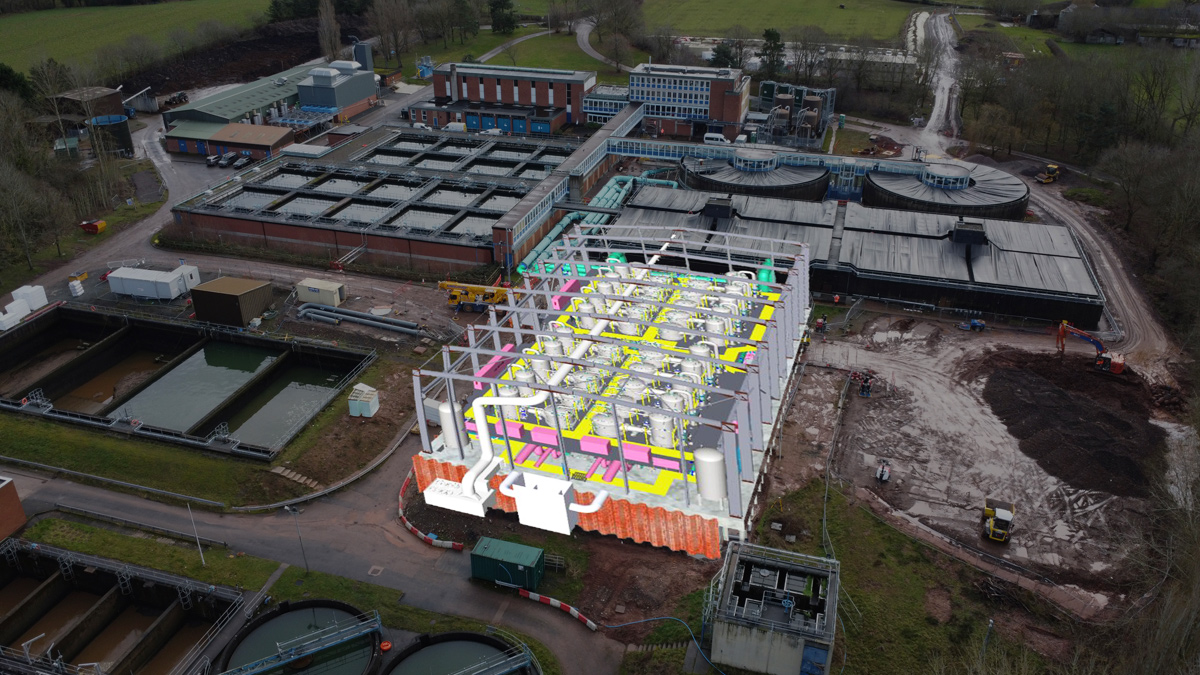

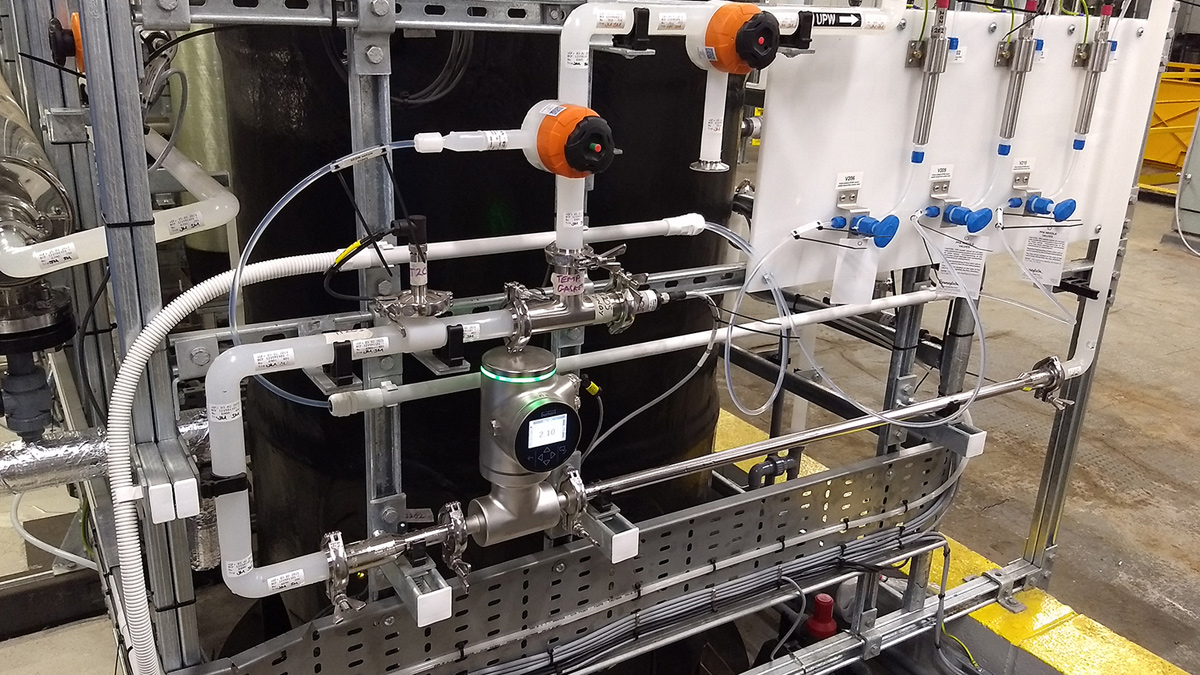

Bürkert’s Type 8905 Online Water Analysis System offers a modular format for analysing water quality, allowing operators to select exactly the parameters they need for each application. Capable of measuring turbidity, iron, chlorine, conductivity, oxidation reduction potential (ORP) and pH, using the same base unit, the 8905 offers simple operation and precision measurement.

A single 8905 unit can handle a multitude of different sample lines, which makes it ideal for monitoring a variety of processes, such as filtration, and identifying any anomalies. For simple operation, each sensor cube can be removed for maintenance without affecting the analysis process for the other parameters, minimising downtime.

Of particular interest is the MS06 iron sensor, which is compatible with any type 8905 system. It features three bottled fluids, reagent, calibrating and cleaning solutions. Beneath every bottle is a load cell, which measures the volume of liquid in each container and these values can be sent to the central control point in the same way as the water quality data.

Precision monitoring

Testing for iron content can present several challenges, especially when it is only present in small quantities. Manual tests can deliver variable results, especially when they are carried out by different staff. However, the MS06 iron sensor can complete a test every 30 minutes and provide accurate results down to 0.03 ppm by volume.

Furthermore, whereas some iron analysis equipment can require extensive maintenance interventions to keep it operational, the 8905 has almost no need for external support.

The Type 8905, equipped with the MS06 iron sensor, offers the opportunity to monitor water quality automatically in both open and closed loop applications and ensure chemical dosing and filtration processes are operating as required. The accuracy and repeatability of this monitoring solution can help to identify process failings, minimise operational costs and offer peace of mind for the quality of the wider production process.

For more infomation: Bürkert Fluid Control Systems | +44 (0)1285 648720

Bürkert Fluid Control Systems is one of the leading manufacturers of control and measuring systems for fluids and gases. The products have a wide variety of applications and are used by breweries and laboratories as well as in medical engineering and space technology. The company employs over 2,200 people and has a comprehensive network of branches in 35 countries world-wide.