Bürkert Fluid Control Systems

Water Analysis System Highlights Water Treatment Improvements for Power Station

A water analysis trial with the 8905 water analysis sensor took place at a gas power plant in Ireland - Image source: shutterstock - Courtesy of Bürkert Fluid Control Systems

The trial generated accurate, reliable results for detecting trace-level impurities and chlorine with Bürkert’s 8905 analysis system and sensors. The results of the six-month trial by an environmental monitoring services company have provided confidence in the repeated accuracy of the data, now enabling investigation of wider plant automation.

Bürkert’s client was tasked to run a water analysis trial at a gas power plant in Ireland. Steam, generated from ultra-purified water, is required to drive the plant’s turbines. Water fed from a semi-covered reservoir passes through a treatment plant featuring a reverse osmosis (RO) system and an electric deionization (EDI) process, which create the required ultra-purified water. Water conductivity from the process has to be accurately measured and reduced to approximately 15 µS and the RO system is tasked with the removal of impurities, which can deteriorate the EDI over time. Impurities penetrating the RO system can also cause stress corrosion cracking in the turbine blades.

The environmental services company was required to report on the water treatment plant’s conductivity as well as levels of chlorine, pH, ORP and turbidity. The plant’s existing analysis equipment didn’t provide sufficient data, and measurement clarity as well as repeatable accuracy were essential. Irregular power demand also meant periods of low flow, which impacted stability of measurement. Specialising in reliable online environmental monitoring, the company selected Bürkert to provide the sensors and water analysis capability as a result of the company’s expertise in rapid, accurate and reliable measurement.

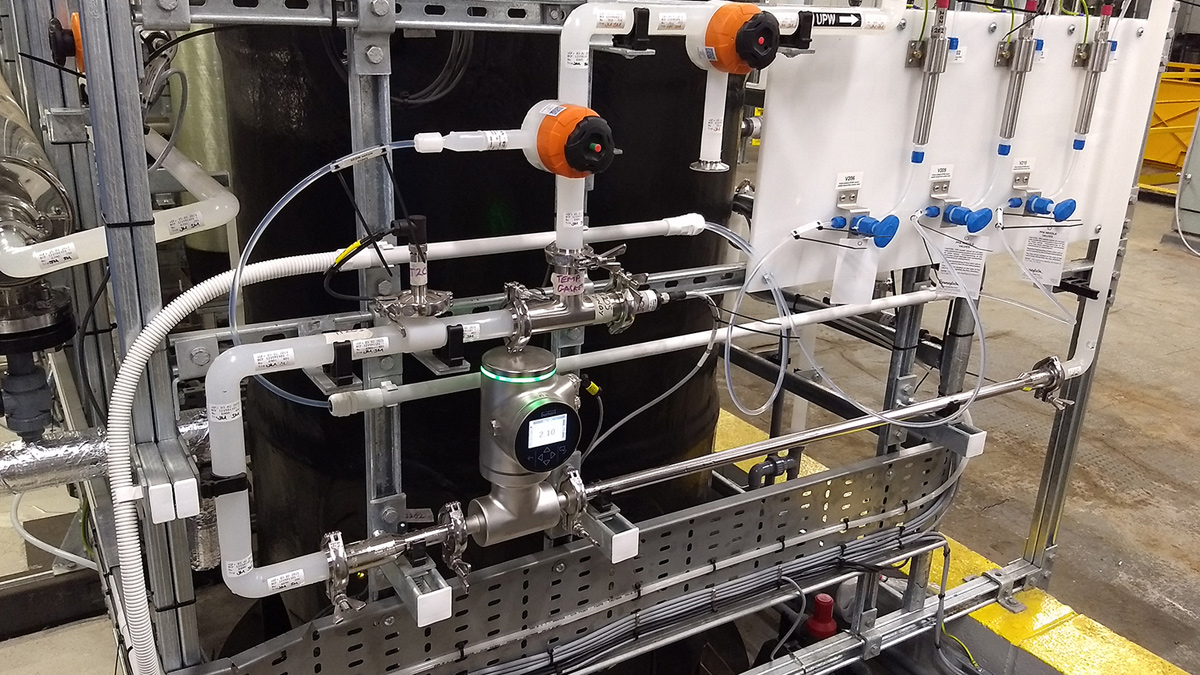

A full suite of Bürkert 8905 Online Analysis System units for monitoring water parameters, combined with Type MS sensor cubes, each suited to monitor a specific characteristic, were installed into a compact panel. The trial monitored the feed into the RO system and while it was originally designed to run for three months, as a result of the Covid pandemic, the sensors were left in place for six months.

The challenge of the reservoir’s low flow was a result of its oversized construction. Designed for a maximum capacity of 50 tonnes of water per hour to support hours of peak power generation, the plant can process as little as 20 tonnes per day when on standby. Typical analytical sensors on a one-inch process line require 2-3,000 litres per hour, whereas Bürkert’s 8905 system, even with five sensors, requires just 30 litres per hour. Even when a continuous pump is required to fulfil the sensors’ minimum flow requirement, the Bürkert system provides significant reduction in wastage and cost.

Throughout the six-month period, the system ran without deviation, not requiring recalibration or inspection, which demonstrated its reliability. This was a crucial requirement for the water monitoring company and also the power plant operator, giving confidence for uninterrupted service and low maintenance requirements.

Bürkert’s 8905 water analysis system and chlorine sensor has a t90 time, the duration that it takes the sensor to measure 90% of the chlorine concentration, of less than 30 seconds.

Crucially, the accuracy and sensitivity of the 8905 system showed chlorine trace not previously identified. Long term, trace levels of chlorine can degrade the RO membranes and ultimately allow the unwanted passage of chlorine through to the EDI, which it can also damage. Furthermore, the customer wanted to avoid any flow of chlorine back into the river system. A carbon filter can now be used upstream of the RO to prevent the inbound flow of chlorine.

For detection accuracy, Bürkert’s 8905 water analysis system and chlorine sensor has a t90 time, the duration that it takes the sensor to measure 90% of the chlorine concentration, of less than 30 seconds, whereas typical industry standards for chlorine sensors have a t90 time from 60 to 180 seconds.

The fast reaction time also means that the 8905 sensor is unaffected by polarization, whereby a sensor measuring zero chlorine for long periods of time can take several hours to react and measure with reliability when small amounts of chlorine are reintroduced. Typical sensors can therefore be unable to measure trace chlorine levels, which can pass through the system before they are able to react. Instead, Bürkert’s 8905 sensor is able to accurately and reliably measure chlorine even at µg/l trace level.

Faster reaction is a result of the chlorine sensor design, which features only a single membrane compared to a typical chlorine sensor which incorporates a membrane pair surrounding an electrolyte buffer. The single membrane of the 8905’s chlorine sensor means that the ions buffer through reduced resistance before chlorine trace is detected by the sensor, creating the faster response rate.

The accuracy of the Type 8905’s additional sensors also identified new data that would be useful to the plant, including pH levels up to pH12, which can be used to pursue further improvements in performance and reliability across the water treatment plant. The sensors also detected a caustic solution used as part of the cleaning process, the results of which will be used to assess the long term impact to the RO system.

Cost was also reduced in system installation. The 8905 system can be installed into a single compact panel, approximately one meter square, as opposed to utilising several larger boards, complete with transmitters. This reduces wiring costs and installation time, as well as footprint. The potential for Ethernet connectivity for plant automation will also reduce the cost of sensor outputs and increase the ease of system integration. The system can be operated by the seven-inch touch display or remotely using Bürkert’s Communicator PC tool.

The results of the trial have identified accurate, repeatable and reliable readings across the analytics, which have identified potential for a more effective water treatment system. These results can then be utilised to deliver improvements across the plant for better reliability and reduced downtime.

For more infomation: Bürkert Fluid Control Systems | +44 (0)1285 648720

Bürkert Fluid Control Systems is one of the leading manufacturers of control and measuring systems for fluids and gases. The products have a wide variety of applications and are used by breweries and laboratories as well as in medical engineering and space technology. The company employs over 2,200 people and has a comprehensive network of branches in 35 countries world-wide.